O que é a linha de envase de garrafas Count

Linha de enchimento de garrafas de contagem é uma linha de produção automatizada usada nas indústrias farmacêutica, nutracêutica e alimentícia para contar e encher com precisão produtos, como comprimidos, cápsulas, gomas ou géis moles, em garrafas.

Em que consiste a linha de envase de garrafas Count?

A linha de envase de garrafas inclui: desembaralhador de garrafas, alimentador de elevação, contador de cápsulas de comprimidos, controlador de peso, inseridor de dessecante, tampadora, seladora de papel alumínio e etiquetadora. Como funciona a máquina?

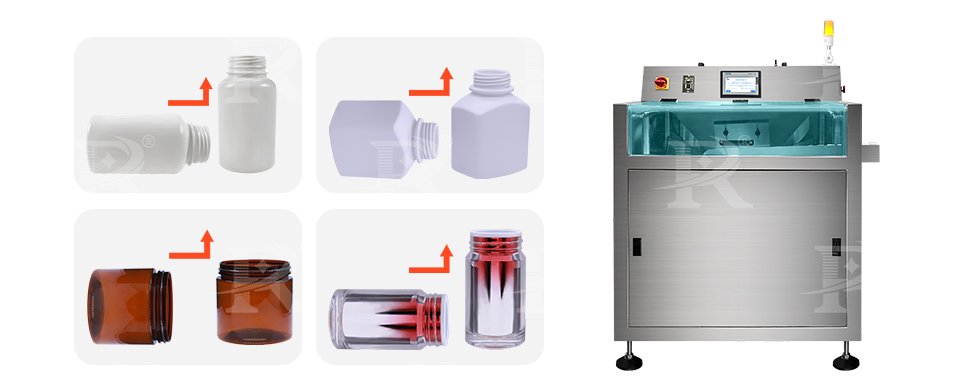

Desembaralhador de garrafas

Desembaralhador de garrafas é uma máquina projetada para orientar e posicionar automaticamente as garrafas corretamente na linha de contagem de cápsulas. O princípio de funcionamento de um desembaralhador de garrafas normalmente envolve as seguintes etapas:

Carregamento de garrafas: garrafas vazias são carregadas em um alimentador ou funil de granel, geralmente em uma orientação aleatória.

Mecanismo de triagem: As garrafas são transferidas da tremonha para um disco giratório, onde são classificadas e guiadas para canais específicos. Esse mecanismo utiliza gravidade, força centrífuga ou vibração para mover as garrafas para o próximo estágio.

Orientação e Alinhamento: À medida que as garrafas se movem pelos canais, elas são guiadas para a posição vertical por trilhos, guias ou funis. As garrafas desalinhadas são corrigidas ou devolvidas à tremonha para outra passagem pelo sistema.

Detecção e Ajuste: Sensores ou detectores mecânicos garantem que apenas garrafas corretamente orientadas passem. As garrafas que não estiverem corretamente alinhadas são redirecionadas de volta para a etapa de triagem.

Descarga e transferência: depois que as garrafas estiverem corretamente orientadas, elas são liberadas em uma correia transportadora em um único arquivo, prontas para serem enchidas ou processadas posteriormente na linha de produção.

Controle de velocidade: o desembaralhador opera em velocidades ajustáveis para acompanhar o ritmo dos processos de enchimento e embalagem, garantindo um fluxo contínuo de garrafas.

Máquina de elevação e alimentação

Alimentador elevatório é uma máquina usada para elevar e alimentar materiais, como comprimidos, cápsulas, gomas ou outros itens pequenos, de um nível inferior para uma posição mais alta na linha de produção. O princípio de funcionamento de um alimentador elevatório geralmente envolve as seguintes etapas:

Carregamento de Material: Os materiais (comprimidos, cápsulas, gomas ou outros itens pequenos) são carregados em uma tremonha ou bandeja de alimentação na base do alimentador de elevação. Isso normalmente é feito manualmente ou automaticamente a partir de uma etapa anterior do processo de produção.

Mecanismo de Transporte: O alimentador de elevação utiliza um mecanismo de transporte, como uma correia, uma caçamba ou um sistema vibratório, para mover os materiais para cima. Em um transportador de caçambas, por exemplo, os materiais são coletados em pequenas caçambas presas a uma correia ou corrente, que gira para elevar os materiais até a altura desejada.

Elevação e Elevação: À medida que o mecanismo de transporte opera, ele eleva os materiais da tremonha para um nível mais alto. A velocidade e o ângulo de elevação geralmente podem ser ajustados para controlar a vazão e atender às necessidades do equipamento a jusante.

Descarga: No topo do elevador, os materiais são descarregados do transportador para uma tremonha de recebimento, rampa ou diretamente para a máquina de contagem de engarrafamento.

Retorno e Recarga: O mecanismo de transporte retorna à posição inicial, pronto para coletar mais materiais do funil e repetir o processo.

Sistema de controle: O alimentador de elevação normalmente é equipado com sensores e um sistema de controle que monitora o nível do material na tremonha e ajusta a taxa de alimentação para garantir um fornecimento contínuo e consistente.

Máquina de contagem de cápsulas de comprimidos

Máquina de contagem de cápsulas de comprimidos Pode contar comprimidos, cápsulas e gomas de 3 a 40 mm em frascos. O princípio de funcionamento de uma máquina de contagem de envase envolve as seguintes etapas:

Alimentação: Comprimidos ou cápsulas são introduzidos na máquina a partir de um funil ou alimentador. Os produtos são normalmente direcionados para uma placa vibratória ou transportador que os distribui uniformemente.

Orientação e Separação de Produtos: Os produtos são distribuídos e alinhados na esteira ou placa vibratória. São guiados em filas únicas, garantindo que cada item seja separado para uma contagem precisa.

Mecanismo de contagem: A máquina utiliza sensores, geralmente ópticos ou infravermelhos, para contar cada item à medida que passa por um ponto designado. Esses sensores detectam e registram cada produto, garantindo uma contagem precisa antes de ser dispensado na garrafa.

Posicionamento das garrafas: As garrafas vazias são alimentadas na esteira e posicionadas sob a calha de distribuição. A máquina garante que cada garrafa esteja corretamente alinhada para receber os produtos contados.

Processo de Envase: Após a contagem do número correto de produtos, eles são dispensados na garrafa. A máquina controla o fluxo para garantir que apenas a quantidade exata de itens seja envasada em cada garrafa.

Máquina de verificação de peso

O controlador de peso é uma máquina utilizada em linhas de produção para garantir que o peso dos produtos embalados atenda aos padrões especificados. O princípio de funcionamento de um controlador de peso envolve as seguintes etapas:

Alimentação do Produto: Após a contagem da máquina de envase, as garrafas passam pela esteira transportadora e entram na balança de controle de peso. A esteira transportadora movimenta os produtos a uma velocidade constante.

Mecanismo de Pesagem: À medida que cada garrafa passa pela plataforma de pesagem ou balança integrada à correia transportadora, o controlador de peso mede seu peso. Isso normalmente é feito usando uma célula de carga de alta precisão, que converte o peso em um sinal elétrico para processamento.

Processamento de Dados: O sistema de controle do controlador de peso compara o peso medido de cada produto com os limites de peso predefinidos. Esses limites definem a faixa de peso aceitável (por exemplo, pesos mínimo e máximo permitidos).

Classificação ou Rejeição: Se o peso do produto estiver dentro da faixa aceitável, ele segue pela esteira até o inseridor de dessecante. Se o produto estiver abaixo ou acima do peso, ele é automaticamente desviado para uma área de rejeição por um empurrador.

Feedback e Ajuste: O controlador de peso pode fornecer feedback em tempo real para a linha de envase de garrafas de contagem, permitindo ajustes no processo de envase ou embalagem caso sejam detectadas inconsistências de peso. Isso ajuda a manter a qualidade consistente do produto e reduz o desperdício.

Registro e Relatório de Dados: O controlador de peso frequentemente registra os dados de pesagem e gera relatórios para fins de controle de qualidade. Esses dados podem ser usados para monitorar tendências de produção, garantir a conformidade com as regulamentações e otimizar o processo de produção.

Máquina de inserção de dessecante

A máquina de inserção de dessecante é usada para inserir automaticamente pacotes de dessecante em garrafas ou recipientes, normalmente nas indústrias farmacêutica, alimentícia ou de embalagens, para manter o conteúdo seco e livre de umidade. O princípio de funcionamento de uma máquina de inserção de dessecante envolve as seguintes etapas:

Fornecimento de dessecante: os pacotes de dessecante são carregados em um sistema de alimentação, geralmente um funil ou compartimento, onde são armazenados e alimentados na máquina.

Separação e Orientação: Os pacotes dessecantes são separados do suprimento a granel e orientados para inserção. Isso geralmente é feito por meio de um mecanismo vibratório ou rotativo que garante que cada pacote seja alimentado individualmente no sistema de inserção.

Posicionamento da garrafa ou recipiente: As garrafas são posicionadas sob o ponto de inserção do dessecante. Um sensor ou sistema de posicionamento garante que cada recipiente esteja corretamente alinhado e pronto para receber o pacote de dessecante.

Mecanismo de inserção: inserido na garrafa ou recipiente. O momento dessa inserção é sincronizado com o movimento das garrafas na esteira para garantir uma operação precisa.

Operação contínua: a máquina opera continuamente, inserindo automaticamente pacotes dessecantes nos recipientes conforme eles passam pela linha, garantindo que o processo de embalagem seja eficiente e consistente.

Máquina de tampar

Máquina de tampar foi projetada para colocar e fixar tampas automaticamente em garrafas ou recipientes como parte de uma linha de produção. O princípio de funcionamento de uma máquina de fechamento envolve as seguintes etapas:

Alimentação com mamadeiras: As garrafas são alimentadas em uma esteira transportadora e movidas em direção à estação de fechamento. A máquina garante que as garrafas estejam corretamente espaçadas e orientadas para o fechamento.

Classificação e Alimentação de Tampas: As tampas são carregadas em um alimentador ou classificador de tampas, que as organiza e alinha. As tampas são então alimentadas em uma calha ou trilho que as guia até o cabeçote de fechamento. Isso garante que as tampas estejam corretamente orientadas antes de serem colocadas nas garrafas.

Colocação da tampa: conforme cada garrafa passa sob a cabeça de fechamento, uma tampa é pega e colocada na abertura da garrafa.

Mecanismo de fechamento: A máquina de fechamento aperta ou fixa a tampa na garrafa. Diferentes tipos de mecanismos de fechamento podem ser usados, dependendo do tipo de tampa e da garrafa:

Tampa de Rosca: A máquina aplica força rotacional para rosquear a tampa na garrafa, garantindo que ela esteja firme e segura.

Tampas de encaixe: para tampas de encaixe, a máquina aplica pressão para baixo para encaixar a tampa no lugar.

Tampas de crimpagem: para tampas de crimpagem, a máquina usa uma ferramenta de crimpagem para selar a tampa no gargalo da garrafa.

Controle de Torque: Em máquinas de fechamento por rosca, o torque aplicado à tampa pode ser controlado com precisão para garantir que ela não fique nem muito frouxa nem muito apertada. Isso é importante para manter a integridade do produto e garantir a segurança do consumidor.

Controle e Verificação de Qualidade: Algumas máquinas incluem sensores ou sistemas de visão para verificar se cada tampa está corretamente colocada e fixada. Se uma tampa estiver faltando, colocada incorretamente ou não apertada conforme as especificações corretas, a garrafa pode ser rejeitada automaticamente ou enviada para recolocação da tampa.

Máquina de selagem de papel alumínio

A máquina de selagem com papel alumínio é usada para selar recipientes com uma camada de papel alumínio, criando um lacre hermético e inviolável. É comumente utilizada nas indústrias alimentícia, farmacêutica e cosmética. O princípio de funcionamento de uma máquina de selagem com papel alumínio envolve as seguintes etapas:

Alimentação de Contêineres: Os contêineres são alimentados em uma correia transportadora e movidos em direção à estação de selagem. A máquina garante que cada contêiner esteja corretamente posicionado para a selagem.

Tampa com papel-alumínio: Os recipientes geralmente têm tampas com um revestimento interno de papel-alumínio. A tampa é colocada no recipiente, com o papel-alumínio posicionado sobre a abertura do recipiente.

Aquecimento por indução: o recipiente passa por uma bobina de indução, que gera um campo eletromagnético de alta frequência. Esse campo induz uma corrente elétrica na folha de alumínio, causando seu aquecimento.

Transferência de calor: O calor gerado na folha de alumínio derrete o revestimento de polímero sensível ao calor na parte inferior da folha. Essa camada de polímero se liga à borda do recipiente, formando uma vedação.

Aplicação de pressão (opcional): Em algumas máquinas, uma almofada ou mecanismo de pressão pode ser usado para pressionar a folha firmemente contra a abertura do recipiente durante o aquecimento, garantindo uma vedação uniforme e segura.

Resfriamento e Solidificação: Após o processo de aquecimento, o polímero esfria e solidifica, criando uma vedação hermética e inviolável entre a folha de alumínio e o recipiente. O recipiente é então liberado da estação de selagem.

Controle e Verificação de Qualidade: Os contêineres lacrados podem passar por uma estação de controle de qualidade, onde sensores ou câmeras verificam a integridade do lacre. Contêineres com lacres defeituosos podem ser rejeitados automaticamente.

Máquina de etiquetagem

Máquina de etiquetagem é usado para aplicar rótulos automaticamente em garrafas. As máquinas de etiquetagem são amplamente utilizadas em indústrias como alimentos e bebidas, farmacêutica, cosmética e de embalagens. O princípio de funcionamento de uma máquina de etiquetagem envolve as seguintes etapas:

Alimentação do produto: As garrafas são alimentadas em uma esteira transportadora que as move em direção à estação de etiquetagem. A máquina garante que cada item esteja corretamente espaçado e orientado para uma aplicação precisa da etiqueta.

Alimentação de Etiquetas: As etiquetas são fornecidas em rolo ou em folha e alimentadas na etiquetadora. A máquina desenrola as etiquetas e as posiciona para aplicação. Um sensor detecta o início de cada etiqueta para garantir o posicionamento preciso.

Detecção e Alinhamento de Etiquetas: Sensores ou marcadores na bobina da etiqueta detectam a posição de cada etiqueta, garantindo que elas estejam alinhadas corretamente antes da aplicação. As etiquetas são descoladas do material de suporte ao chegarem ao ponto de aplicação.

Aplicação da etiqueta: À medida que o produto passa pela estação de etiquetagem, a máquina aplica a etiqueta na superfície do produto. Dependendo do tipo de etiquetadora, são utilizados diferentes métodos:

Etiquetagem Envolvente: A etiqueta envolve produtos cilíndricos ou redondos, como garrafas ou latas. O produto pode girar durante a aplicação para garantir cobertura total.

Etiquetagem frontal e traseira: etiquetas separadas são aplicadas nas superfícies frontal e traseira do produto. A máquina posiciona precisamente cada etiqueta no lado correto.

Etiquetagem superior ou inferior: as etiquetas são aplicadas nas superfícies superior ou inferior de produtos planos ou recipientes.

Etiquetagem de cantos ou bordas: para embalagens ou caixas, as etiquetas podem ser aplicadas em cantos ou bordas, envolvendo duas superfícies adjacentes.

Aplicação de pressão: Um rolo ou pincel pode aplicar uma leve pressão para garantir que a etiqueta adira suavemente e com segurança à superfície do produto, sem rugas ou bolhas.

Sistema de Sensores e Controle: A máquina utiliza sensores para monitorar o processo de etiquetagem, garantindo que cada etiqueta seja aplicada corretamente e na velocidade ideal. O sistema de controle pode ajustar a velocidade, a posição e o alinhamento das etiquetas para corresponder a diferentes tamanhos e formatos de produtos.

Inspeção e Controle de Qualidade: Após a etiquetagem, o produto passa por uma estação de inspeção onde sensores ou câmeras verificam o posicionamento, o alinhamento e a aderência das etiquetas. Produtos com etiquetas incorretas ou ausentes podem ser rejeitados ou enviados para nova etiquetagem.

Seja uma única máquina ou uma linha de enchimento de contagem de cápsulas inteiras, ruidapacking pode fornecer serviços completos.