- Lar

- Máquina de enchimento de cápsulas

Máquina de enchimento de cápsulas

Classificação da máquina de enchimento de cápsulas

| Modelo de Máquina | NJP-400C | NJP-800C | NJP-1500D | NJP-2600C | NJP-3800D | NJP-5500C |

| Saída Máxima | 24000 peças/h | 48000 peças/h | 90000 peças/h | 150000 pcs/h | 228000 peças/h | 330000 peças/h |

| Compatibilidade de tamanhos de cápsulas | 000,00,0,1,2,3,4,5# | |||||

| Poder | 3KW | 5KW | 5.5KW | 8KW | 10,5KW | 11KW |

| Peso | 600 kg | 900 kg | 1200Kg | 1500 kg | 2200Kg | 3000Kg |

| Dimensão | 1000×710×1900mm | 1100×910×2100 mm | 1490×1260×2150mm | 1650×1490×2150mm | 1980×1850×2200mm | 2400x2050x2300mm |

| Modelo | CGN-208 | CGNT-209 |

| Saída | 15000-30000pcs/h | 40000pcs/h |

| Cápsula aplicável | 000#、00#、0#、1#、2#、3#、4#、5# | |

| Fonte de energia | 2,12 kW | 2,2kw |

| Poder | 380/220V 50Hz (personalizável) | |

| Peso líquido | 400 kg | 405 kg |

| Tamanho da embalagem | 1640*720*1700 mm | 1640*720*1700 mm |

| Modelo | CGNL-300 | NJPL-100C | NJPL-300C | NJPL-600C |

| Saída | 15000-28000pcs/h | 100 peças/min | 300 peças/min | 600 peças/min |

| Compatibilidade de tamanhos de cápsulas | 00#, 0#, 1#, 2#, 3# | |||

| Potência total | 2,12 kW | 3,5KW | 5KW | 6KW |

| Poder | 380/220V 50Hz (personalizável) | |||

| Peso | 400KG | 500KG | 750KG | 900KG |

| Dimensão (L*W*H) | 1300*800*1750mm | 700*800*1700mm | 860*960*1800mm | 960*1000*1900mm |

Não tem a certeza de qual a melhor máquina para si? A nossa equipa pode apresentar uma proposta com base nas suas necessidades e orçamento!

Máquina automática de enchimento de cápsulas

Benefícios

- Menos custos de mão de obra

- Produção superior à semi-automática com um operador

- Automação integrada para completar a cápsula

- Todo o processo sem poluição

Aplicação:

- tamanho:#000 a #5

- Ingredientes: pellets, pó, grânulos

Máquina de enchimento de cápsulas semiautomática

- Fácil de utilizar

- Custos de máquina mais baixos

- Maior rendimento com mais operadores

- tamanho:#000 a #5

- Ingredientes: pellets, pó, grânulos

Máquina de enchimento de cápsulas semiautomática

A máquina envasadora de cápsulas semi-automática pode encher pó, grânulos, pellets e líquidos em cápsulas duras, adequadas para cápsulas de tamanho ...

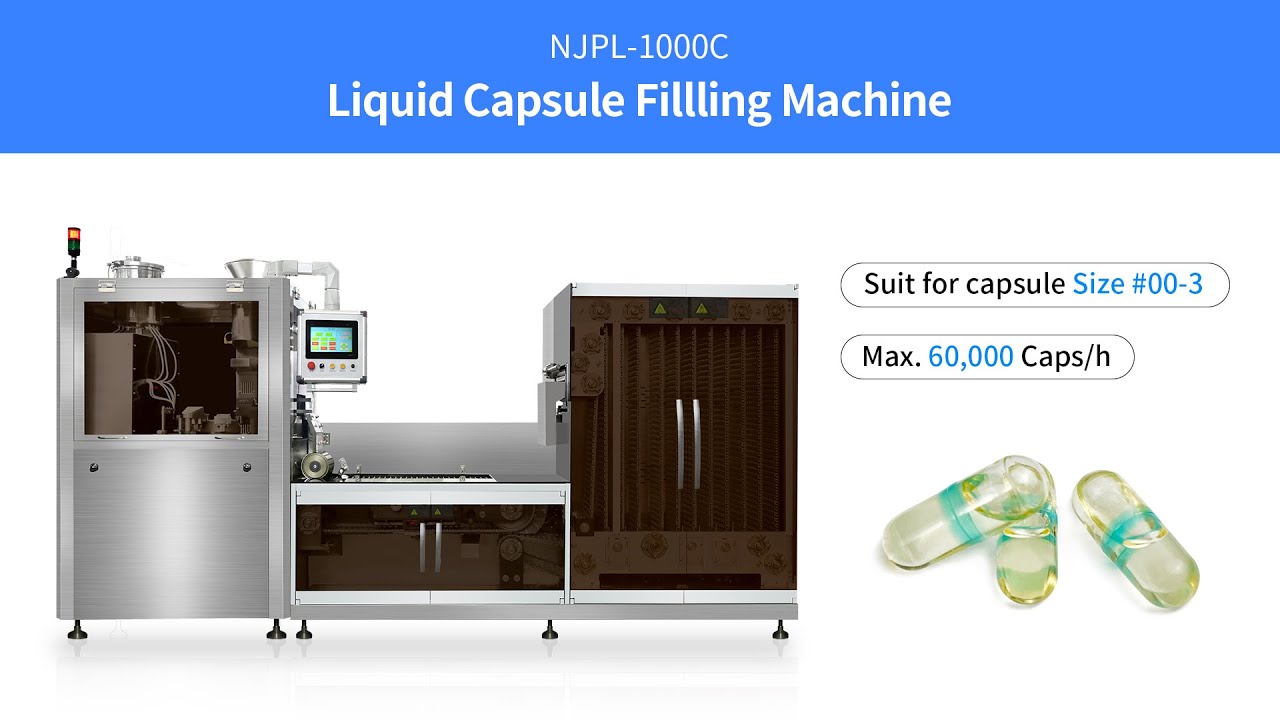

Máquina de enchimento de cápsulas líquidas

Benefícios

- Tecnologias de ponta sem fugas

- Todo o processo sem poluição

- Aplicação de vários líquidos

Aplicação:

- tamanho: #000 a #3

- Ingredientes: líquido, óleo, líquido/mini cápsula, líquido/mini comprimido, líquido/pellets

Máquina de enchimento de cápsulas líquidas automática NJPL-330C

A máquina automática de enchimento de cápsulas para líquidos NJPL-330C enche e sela óleos, suspensões, pastas e soluções viscosas em cápsulas duras (tamanhos ...

Um investimento inteligente para a indústria farmacêutica

Ampla aplicação

Alta precisão

Custo-efetivo

Oficina sem confusão

Nós cuidamos de você com um serviço completo

Garantia vitalícia

Entrega rápida em 7 dias

Serviço online 24 horas por dia, 7 dias por semana

Perguntas frequentes

- Lubrificar regularmente o excêntrico para o manter em bom estado.

- Desmontar e limpar a estação de enchimento para retirar o excesso de material, a fim de evitar entupimentos e ferrugem, após a conclusão da produção.

- Adicionar regularmente óleo lubrificante à bomba de vácuo e limpar o pó.

- Encher regularmente o depósito de água com água suficiente para cobrir metade do corpo do barril.

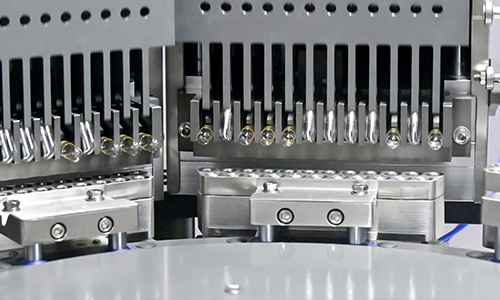

Princípio de funcionamento da máquina de enchimento de cápsulas

Etapa #1: Separação de cápsulas

A máquina separa as cápsulas vazias em metades individuais, normalmente utilizando mecanismos mecânicos ou de vácuo.

Etapa #2: Material de enchimento

O material de enchimento desejado, como pós ou grânulos, é carregado numa tremonha.

Etapa #3: Fecho da cápsula

A máquina junta as metades da cápsula, alinha-as e fecha-as de forma segura utilizando pressão mecânica, sucção por vácuo ou uma combinação de ambos.

Etapa #4: Ejeção

Uma vez fechadas, as cápsulas são libertadas da máquina, quer para um recipiente, quer para uma embalagem posterior.

O que é uma máquina de enchimento de cápsulas?

Uma máquina de enchimento de cápsulas é um dispositivo utilizado na farmacêutico, nutracêutico, e indústrias de ervas para automatizar o processo de enchimento de cápsulas vazias com várias substâncias, tais como pós, grânulos, pellets ou líquidos.

É constituída por diferentes componentes, incluindo um depósito de cápsulas, um mecanismo para separar e orientar as cápsulas, um sistema de enchimento, um mecanismo de fecho e um sistema de ejeção.

A máquina permite um enchimento eficaz e preciso das cápsulas, garantir uma dosagem exacta e uniforme. Ajuda a aumentar a velocidade de produção, a reduzir os custos de mão de obra e a manter o controlo de qualidade nos processos de fabrico de cápsulas.

Principais tipos de cápsulas

Cápsulas de casca dura

- As cápsulas de invólucro duro, também conhecidas como cápsulas de duas peças, são compostas por secções separadas de tampa e corpo que se encaixam para envolver o material de enchimento. A tampa e o corpo são normalmente feitos de gelatina ou de materiais vegetais.

- As cápsulas duras oferecem uma excelente proteção do produto, estabilidade e caraterísticas invioláveis. São normalmente utilizadas para pós secos, grânulos ou pequenas partículas sólidas.

Cápsulas de casca mole

- As cápsulas de invólucro mole são compostas por um invólucro único e flexível de gelatina ou de origem vegetal. São frequentemente designadas por cápsulas moles ou cápsulas de gelatina mole. As cápsulas moles são normalmente preenchidas com materiais líquidos ou semi-sólidos, tais como óleos, suspensões ou pastas.

- O invólucro mole oferece vantagens como uma maior biodisponibilidade para formulações à base de lípidos, uma maior estabilidade para compostos sensíveis à luz e facilidade de deglutição.