30 maja 2025 r., Guangzhou, Ruida Packing ustanowiła nowy punkt odniesienia w kompleksowych rozwiązaniach farmaceutycznych dzięki udanemu wdrożeniu dwóch w pełni zintegrowanych linii produkcyjnych dla klienta Aslam z siedzibą w Zjednoczonych Emiratach Arabskich. Projekt obejmujący linię do szybkiego liczenia i precyzyjnego napełniania proszkiem pokazuje zaangażowanie Ruida w profesjonalną obsługę techniczną i doskonałość usług pod klucz.

Wyzwanie klienta: Ograniczenia budżetowe spełnione z zachowaniem integralności inżynierskiej

Mając do dyspozycji ograniczony kapitał na sprzęt, Aslam ocenił 5 chińskich dostawców. Ruida wygrała kontrakt nie dzięki najniższej cenie, ale dzięki niezachwianej postawie Business Managera Owena:

„Owen odpowiedział natychmiast, nawet o północy swojego czasu. Gdy rozwiązania nie były wykonalne, mówił to wprost. Inni sprzedawcy obiecywali wszystko z góry, ale potem się wycofywali”. Aslam.

Awaria techniczna: dwie linie produkcyjne

1. Linia liczenia i butelkowania (zgodna z cGMP)

Rozszyfrowywacz butelek, elektroniczny licznik tabletek i kapsułek(100 butelek/min), waga kontrolna, podajnik pochłaniacza wilgoci, zakręcarka, zgrzewarka indukcyjna, etykieciarka.

2. Linia napełniania proszkiem (dokładność 0,1 g)

Podajnik wibracyjny, automatyczna maszyna do napełniania proszkiem (zakres 25-500 g), zakręcarka gwiazdowa, zgrzewarka folii z zabezpieczeniem przed naruszeniem, etykieciarka wrażliwa na położenie, maszyna do pakowania w rękawy.

Różnica w usłudze Ruida: gwarancja 4-filarowa

Przejrzystość produkcji w czasie rzeczywistym

Owen co tydzień udostępniał zdjęcia i materiały wideo z produkcji, co rozwiało obawy międzynarodowych nabywców związane z „czarną skrzynką”.

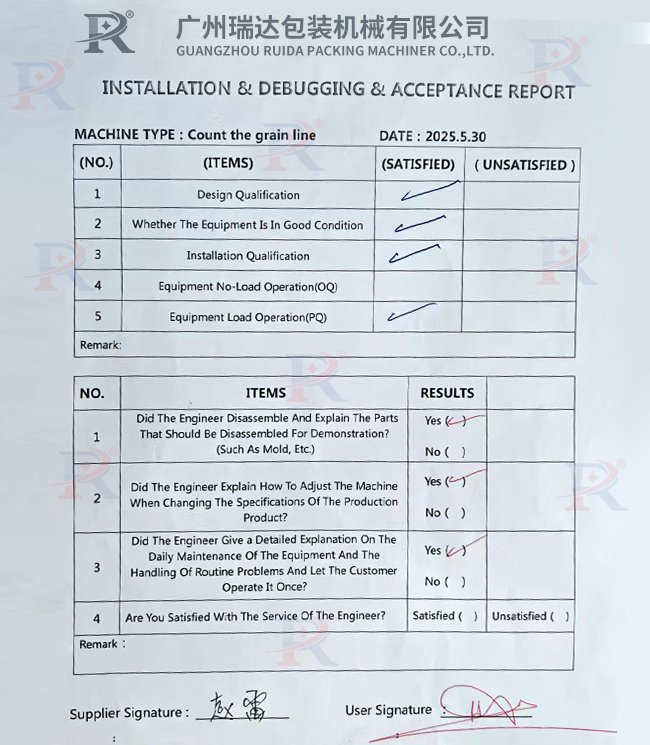

3-etapowe szkolenie na miejscu (prowadzone przez inżyniera Zhao)

| Faza | Proces | Wynik dla klienta |

| Demonstracja | Konfiguracja maszyny na próbę i dostrajanie parametrów | Zrozumieć logikę operacyjną |

| Operacja kierowana | Praktyczna regulacja różnych materiałów | Główne protokoły przełączania |

| Niezależna Walidacja | Inżynierowie klienta działają pod nadzorem | Ocena kompetencji zaliczona/niezaliczona |

„Inżynier Zhao szkolił nas, aż mogliśmy wykonywać 8-godzinne partie bez błędów. To nie było szkolenie, to był transfer wiedzy”. Opinia zespołu Aslam.

Integracja konserwacji zapobiegawczej

Zdalna diagnostyka umożliwia rozwiązanie problemów 70% bez konieczności wizyty na miejscu.

Pełna dokumentacja

Instrukcje wielojęzyczne (arabski/angielski).

Pełny zestaw filmów instruktażowych dotyczących rozwiązywania problemów.

Dlaczego warto wybrać Ruidapacking

Brak ukrytych możliwości: Ograniczenia maszyny są udokumentowane przed podpisaniem umowy.

Pełna odpowiedzialność od FOB do uruchomienia: Jeden punkt odpowiedzialności od fabryki do uruchomienia produkcji.

Wbudowana zgodność z cGMP: Wszystkie maszyny zawierają możliwe do walidacji szablony IQ/OQ/PQ.

Wpływ na branżę

Ten projekt podkreśla rosnący trend: 62% firm farmaceutycznych na rynkach wschodzących obecnie stawia na pierwszym miejscu uczciwość techniczną, a nie najniższe ceny (badanie PharmaTech 2025). Rozwiązanie Ruidy wyeliminowało:

Obawy logistyczne (niedopasowanie sprzętu)

Luki w szkoleniu (operatorzy liniowi po raz pierwszy)

Ryzyko przestoju (nieplanowana konserwacja)

Werdykt klienta: Redefinicja wartości

„Ruida udowodniła, że 'opłacalność' oznacza niezawodność na całe życie — nie tylko początkowe oszczędności. Ich inżynierowie zostali 3 dodatkowe dni, aż nasza linia proszkowa osiągnęła 99,2% OEE. To prawdziwe partnerstwo”. powiedział Aslam.