- Dom

- Maszyna do pakowania gotowych torebek

Maszyna pakująca Doypack

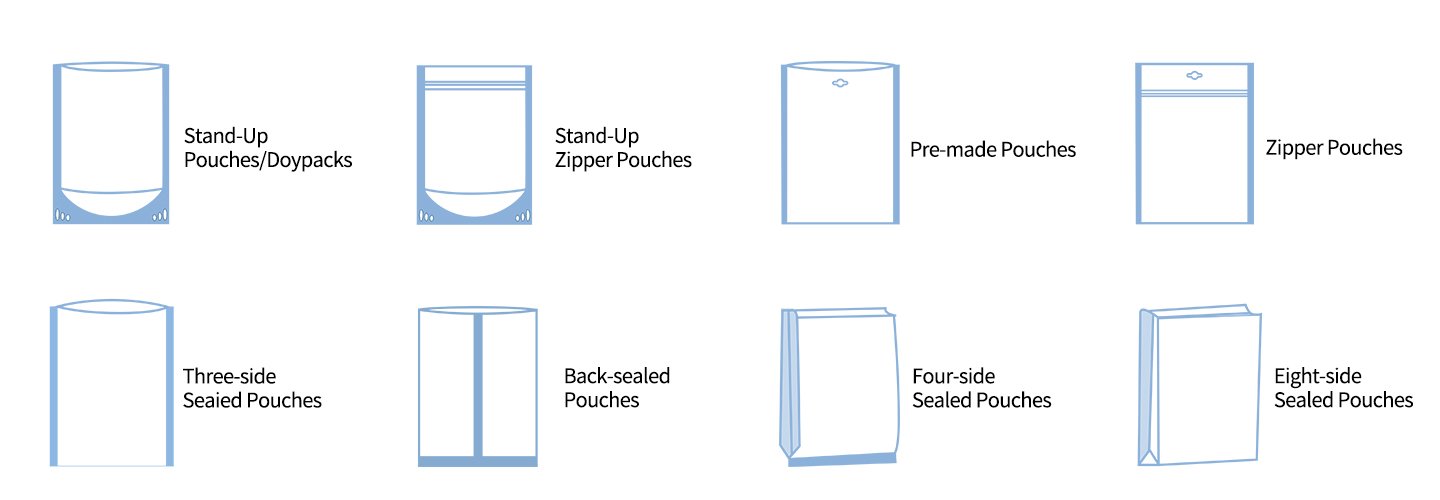

Gotowe maszyny pakujące w saszetki automatyzują szybkie napełnianie i zamykanie stojących saszetek, płaskich saszetek i saszetek z wylewką. Są niezbędne do wydajnego pakowania produktów stałych, płynnych i półstałych w różnych branżach. Kluczowe zastosowania obejmują farmaceutyki (tabletki, kapsułki, proszki), żywność i napoje (żelki, cukierki, przekąski, kawa, sosy), pielęgnację osobistą i kosmetyki (balsamy, szampony, kremy), karmę dla zwierząt, chemikalia. Te maszyny doskonale radzą sobie z obsługą gotowych, zadrukowanych saszetek, oferując precyzyjne dozowanie, solidne uszczelnienie dla integralności produktu i higieniczną obsługę. Idealne do średnich i dużych wolumenów produkcji, gotowe maszyny pakujące w saszetki usprawniają operacje, poprawiają prezentację produktu, zapewniają świeżość i bezpieczeństwo produktu oraz znacznie obniżają koszty pracy ręcznej.

Aplikacja:

Gotowa stojąca maszyna pakująca w torebki z zamkiem błyskawicznym może pakować kapsułki, żelki, cukierki i kawę do różnego rodzaju torebek.

Przepływ pracy na każdym stanowisku roboczym

Maszyna pakująca w torebki to profesjonalna, gotowa maszyna pakująca w torebki do pakowania proszków, płynów i średnich torebek w większe torebki, takie jak torebki stojące i torebki z suwakiem. Maszyna oferuje w pełni zautomatyzowane funkcje, w tym pobieranie torebek, kodowanie, otwieranie torebek, otwieranie zamka błyskawicznego, napełnianie materiałem, dozowanie, wydmuchiwanie powietrza (lub przepłukiwanie azotem w celu zachowania świeżości), układanie torebek, siatkowanie i wydawanie gotowego produktu.

Cechy maszyny

Firma Ruidapacking zobowiązuje się do produkcji maszyn o najwyższej jakości, spełniających standardy GMP, a jednocześnie charakteryzujących się wydajnością i użytecznością.

Szerokie zastosowanie

Nadają się do pakowania różnorodnych materiałów do gotowych torebek, w tym cukierków, orzechów, przetworów, proszków, granulek, saszetek i płynnych pulp.

Całkowicie zamknięta konstrukcja

Ze stali nierdzewnej 316L używanej do części mających kontakt z materiałami, spełniającej wymagania cGMP. Wysoka wodoodporność umożliwia łatwe czyszczenie wodą i wygodną konserwację.

Regulacja jednym przyciskiem

Regulacja szerokości worka odbywa się automatycznie za pomocą silnika z synchronizacją 8 stacji roboczych, co umożliwia wymianę worka w ciągu 2 minut.

Parametry techniczne

Wybierz najlepszą maszynę biorąc pod uwagę rozmiar saszetek.

| Model | RD-GD-200Pro | RD-GD-260Pro | RD-GD-300Pro | RD-GD-360Pro |

| Wyjście | 60 saszetek/min | 50 saszetek/min | 50 saszetek/min | 50 saszetek/min |

| Rozmiar saszetek | Dł.: 90-360 mm Szer.: 100-220 mm | Dł.: 150-360 mm Szer.: 150-270 mm | Dł.: 190-460 mm Szer.: 200-310 mm | Dł.: 260-510 mm Szer.: 250-360 mm |

| Moc | 3,5 kW | 4,5 kW | 4,5 kW | 4,5 kW |

Produkty wspomagające

Automatyczna maszyna do liczenia cukierków butelkowanych

Automatic Bottling Candy Counting Machine with its efficient and accurate counting capabilities are widely used in pharma, food, Health care ...

Automatyczna maszyna do kapsułek farmaceutycznych

Automatic Pharmaceutical Capsule Machine: GMP-compliant, 90,000 capsules/h, ±1% dosing accuracy, supports 000#-5# capsules. Ideal for pharma & nutraceuticals.

Automatyczna maszyna do tabletkowania

Automatic tablet press machine involves compressing powder or granulated into uniform quality tablets through a series of precisely controlled ...

Dostawca jakości Fortune 500

Klienci mówią, że jesteśmy dobrzy

Pochwały od SINOPHARMA, GSK, USPharma, Atlantic Grupa, Robinson Pharma...

Zarządzanie 6S

Sprawdzamy każdy proces, aby upewnić się, że maszyny spełniają wymagania CE, cGMP, ROHS, FDA ...

Forma może być dostosowana

Dostępne w różnych rozmiarach i wymiarach kapsułek i tabletek w zależności od potrzeb.

Projekty współpracy

Wystarczy podać rozmiar pęcherzy, a nasi inżynierowie zajmą się resztą.

Debugowanie na miejscu na całym świecie

Globalne centrum obsługi klienta w Stanach Zjednoczonych jest w gotowości. Powinieneś być odpowiedzialny za bilety lotnicze inżynierów w obie strony, zakwaterowanie i wyżywienie + $350/godz.

Często zadawane pytania

Bezpłatny projekt układu niestandardowego: Zoptymalizuj swój plan piętra, skorzystaj z bezpłatnego doradztwa ekspertów w zakresie planowania rozmieszczenia maszyn.

Kompleksowa dokumentacja techniczna i przewodniki rozwiązywania problemów: Zminimalizuj przestoje dzięki natychmiastowemu dostępowi do instrukcji i rozwiązań typowych problemów.

Zdalna pomoc wideo w czasie rzeczywistym:Nawiąż bezpośredni kontakt ze starszymi inżynierami w celu szybkiego rozwiązania złożonych problemów.

Uproszczona wysyłka globalna:Bezproblemowa dostawa DDP/DDU pod Twoje drzwi, na całym świecie.

Lokalna instalacja i szkolenie: Konfiguracja na miejscu, uruchomienie i szkolenie operatora przez naszych certyfikowanych techników. Ciesz się prawdziwym spokojem ducha.

Roczna ocena wyników:Proaktywne kontrole w celu zapewnienia, że Twój sprzęt działa z maksymalną wydajnością rok po roku.

W przypadku linii pakujących gotowe torebki, kluczowa decyzja o wyborze wagi wielogłowicowej lub maszyny liczącej kapsułki tabletkowe jako sprzętu pomocniczego zależy od atrybutów obsługiwanego materiału. Te dwie technologie oferują wyraźne zalety i są dostosowane do konkretnych zastosowań. Wybór niewłaściwej maszyny może prowadzić do obniżenia wydajności, niewystarczającej dokładności, dużego marnotrawstwa materiału, a nawet awarii operacyjnej.

Poniżej szczegółowo analizujemy kryteria doboru, mocne strony i ograniczenia każdego urządzenia na podstawie kluczowych cech materiałowych:

1. Właściwości materiału

Forma fizyczna

Granulki, płatki, pałeczki, kawałki (regularne/nieregularne ciała stałe): Możliwymi opcjami są zarówno waga wielogłowicowa, jak i maszyna napełniająca licząca; ostateczny wybór zależy od innych właściwości.

Drobne cząstki: Zwykle lepiej nadają się do maszyn liczących.

Proszki, pasty, płyny, materiały lepkie: Ani wielogłowicowa napełniarka wagowa, ani automatyczne maszyny liczące nie są odpowiednie. Wymagają one sprzętu do napełniania objętościowego (napełniacze ślimakowe, napełniacze tłokowe, napełniacze do cieczy) lub wag netto.

Waga/rozmiar indywidualny

Duża i stosunkowo jednolita waga jednostkowa: (duże ciasteczka, tabliczki czekolady, całe owoce, części zabawek) Wielogłowicowe wagi kombinowane zazwyczaj oferują zalety w zakresie wydajności i opłacalności.

Bardzo mała lub bardzo zmienna waga jednostkowa: (małe pigułki, nasiona, żelki, mały sprzęt) Automatyczne elektroniczne maszyny liczące wyróżniają się precyzją i minimalizacją odpadów. Wagi wielogłowicowe mają problemy z kontrolą dokładności w przypadku bardzo lekkich przedmiotów, a małe przedmioty są podatne na utratę poprzez „odlatywanie” (napowietrzanie) w pojemnikach ważących podczas pracy.

2. Wagi wielogłowicowe

Materiał jest rozprowadzany z głównego podajnika wibracyjnego do wielu (zwykle 8–24) niezależnych wiader wagowych (lejów wagowych). System komputerowy stale odczytuje wagę w każdym wiadrze i używa algorytmu łączonego ważenia, aby szybko zidentyfikować grupę wiader, których łączna waga jest najbliższa wadze docelowej. Wybrane wiadra są rozładowywane jednocześnie do leja zbiorczego poniżej, kierując materiał do woreczka opakowaniowego.

Zalety

Duża prędkość: Zasada łączonego ważenia umożliwia wyjątkowo dużą prędkość ważenia (zwykle 100–200 torebek/minutę, przy czym modele o dużej prędkości przekraczają 300 torebek/minutę), co sprawia, że jest to preferowany wybór w celu maksymalizacji wydajności produkcji.

Wysoka dokładność: W przypadku materiałów sypkich o umiarkowanej wadze jednostkowej wagi wielogłowicowe osiągają bardzo wysoką dokładność ważenia (±0,1 g do ±1 g lub lepszą, w zależności od materiału i wagi docelowej). Algorytm łączony skutecznie kompensuje indywidualne wahania wsadu.

Szeroki zakres wagowy: Możliwość obsługi opakowań o wadze od kilku gramów do kilku kilogramów poprzez dostosowanie docelowej wagi i rozmiaru wiadra, co zapewnia dużą wszechstronność.

Idealny do materiałów sypkich: umożliwia płynne i wydajne przetwarzanie granulek, płatków, brył i innych materiałów sypkich.

Relatywnie łatwe czyszczenie i konserwacja: Posiada stosunkowo standaryzowaną konstrukcję; części mające kontakt z materiałem (podajnik wibracyjny, pojemniki) są zazwyczaj odłączalne w celu czyszczenia.

Wady

Problemy z materiałami o słabym przepływie: Materiały podatne na przywieranie, zbrylanie, tłuste lub wilgotne mogą łatwo zatykać podajnik wibracyjny, zasobniki buforowe lub pojemniki wagowe, co prowadzi do nierównomiernego podawania, zmniejszenia dokładności, a nawet zatrzymania maszyny.

Wyzwania związane z małymi/bardzo lekkimi materiałami: Ekstremalnie małe lub lekkie przedmioty (drobne nasiona, małe pigułki) są podatne na rozproszenie przepływu powietrza („odlatywanie”) w pojemnikach ważących, co powoduje utratę materiału. Zalety dokładności również maleją w przypadku bardzo małych wag docelowych.

Możliwe uszkodzenia delikatnych produktów: Ruch obrotowy podajnika wibracyjnego i pojemnika wyładowczego może powodować uderzenia i tarcie, co może prowadzić do uszkodzenia bardzo delikatnych produktów (chipsy ziemniaczane).

Trudności z materiałami o nieregularnym/splątanym kształcie: Długie, płaskie lub włókniste przedmioty mogą zaplątać się lub zablokować w prowadnicach podajnika wibracyjnego lub wlotach pojemników.

Podaje wagę, nie liczbę: Wyprowadza docelową wagę, a nie dokładną liczbę sztuk. Nieodpowiednie do zastosowań wymagających dokładnych ilości (przedmioty sprzedawane według liczby sztuk).

3. Elektryczny Maszyny liczące

Maszyny do butelkowania zliczają poszczególne elementy, wykorzystując separację fizyczną lub technologię rozpoznawania obrazu, i je liczą. Typowe typy obejmują:

Maszyna licząco-napełniająca: Przedmioty ustawiają się w kolejce na wibrujących szynach i są liczone za pomocą czujników fotoelektrycznych.

Maszyna inspekcyjna z kamerą CCD i funkcją liczenia: Szybkie kamery rejestrują obrazy spadających przedmiotów, a oprogramowanie do przetwarzania obrazu identyfikuje i liczy poszczególne jednostki.

Zalety

Zapewnia dokładną liczbę sztuk: Jedyne rozwiązanie dla zastosowań wymagających precyzyjnej liczby (produkty farmaceutyczne, żelki, cukierki, komponenty elektroniczne).

Doskonała obsługa materiałów o słabym przepływie: ogólnie rzecz biorąc przewyższa wagi wielogłowicowe w przetwarzaniu materiałów wilgotnych, oleistych lub lepkich, przy zmniejszonym ryzyku zatykania.

Doskonale sprawdza się w przypadku małych granulek: Idealnie nadaje się do precyzyjnego i mało marnowanego liczenia małych tabletek, nasion i cukierków.

Skuteczne radzenie sobie z nieregularnymi kształtami: Zaawansowani liczniki wzrokowe potrafią dokładnie identyfikować i liczyć przedmioty o zróżnicowanej i trudnej geometrii.

Małe straty materiału: Liczenie zazwyczaj pozwala uniknąć odwracania pojemnika wagowego, minimalizując straty spowodowane „odlatywaniem” lub resztkami produktu.

Niski poziom hałasu: Mniejsza liczba elementów wibracyjnych w porównaniu do wag wielogłowicowych zazwyczaj przekłada się na niższy poziom hałasu.

Wady

Niższa prędkość: Prędkość absolutna jest zazwyczaj niższa niż w przypadku wag wielogłowicowych (szczególnie w przypadku małych przedmiotów). Szybkie liczniki wizyjne mogą osiągać 100-150 sztuk, ale przekłada się to na niższe prędkości pakowania (60-90 saszetek/minutę dla opakowań po 100 sztuk) w porównaniu z szybkimi wagami.

Dokładność wagi zależy od jednorodności jednostki: Dokładność liczenia wynosi 100%, ale dokładność wagi paczki zależy wyłącznie od spójnej wagi poszczególnych przedmiotów. Znaczne wahania wagi (nieregularne rozmiary suszonych owoców, orzechów) powodują duże wahania wagi paczki.

Wrażliwość na zlepianie się przedmiotów: Jeśli dwa lub więcej przedmiotów skleja się ze sobą i jest liczone jako jeden, następuje zaniżenie wyniku. (Przykład rozwiązania: Nasz specjalistyczny licznik słodyczy radzi sobie z zlepianiem się dzięki 4 kluczowym cechom:)

Mieszadło z kolcami do podawania żelków: zapobiega układaniu się żelków w pionie.

Wałek rozprowadzający zapobiegający zbrylaniu: zapewnia równomierne rozprowadzanie partii materiału, zapobiegając przywieraniu.

Panele z wgłębieniami teflonowymi: całkowicie oddzielają żelki i umożliwiają płynne, szybkie przesuwanie.

Powiększony otwór wylotowy PTFE: zmniejsza zatykanie, zwiększając prędkość o 58%.

Dobór skomplikowanego sprzętu: Różne typy liczników różnią się znacząco pod względem przydatności materiałów, dlatego dobór optymalnych rozwiązań wymaga specjalistycznej wiedzy i testów.

Wysoki koszt systemów wizyjnych: Początkowa inwestycja w wydajne systemy wizyjnego liczenia może być znacząca i często przekraczać koszty wag wielogłowicowych.

Ograniczone możliwości w przypadku dużych/ciężkich przedmiotów: Liczenie bardzo dużych kawałków (całych tabliczek czekolady, dużych zabawek) jest często niepraktyczne pod względem konstrukcyjnym, wolniejsze i mniej opłacalne niż stosowanie wag wielogłowicowych.

4. Podsumowanie i przewodnik po wyborze sprzętu

| Funkcja | Poleć wagę wielogłowicową | Poleć maszynę do automatycznego liczenia |

| Wymagania podstawowe | Priorytetem jest docelowa waga; dąż do maksymalnej prędkości i wydajności | Dokładna liczba sztuk jest niezbędna, a właściwości materiału uniemożliwiają ważenie |

| Płynność materiału | Dobry (suchy, sypki) | Słaby/średni (tłusty, wilgotny, lepki, podatny na tworzenie się mostków) |

| Forma materiału | Głównie granulki, płatki, kawałki | Głównie drobne cząstki, mikrogranulki, kształty nieregularne, płaskie, wydłużone przedmioty |

| Waga indywidualna | Cząsteczki średnie do dużych lub małe, ale jednorodne | Bardzo małe przedmioty lub przedmioty o dużej zmienności wagi, wymagające liczenia sztuk |

| Dokładność pakowania | Wysoka dokładność pomiaru wagi (±0,1 g – ± 1 g) | Dokładność liczenia 100% (Dokładność ważenia zależy od jednorodności poszczególnych sztuk) |

| Prędkość | Bardzo wysokie (100-300+ saszetek/minutę) | Średnio-wysoki (zależy od rozmiaru przedmiotu i technologii liczenia; zwykle niższy niż w przypadku wag) |

| Aplikacje | Przekąski (chipsy ziemniaczane/orzechy/słodycze), mrożonki, karma dla zwierząt, ziarna kawy, sprzęt, granulaty chemiczne | Produkty farmaceutyczne (tabletki/kapsułki), suplementy, nasiona, żelki, komponenty elektroniczne, artykuły o dużej wartości sprzedawane na sztuki |

5. Najlepsze zalecenia dotyczące praktyk wspierających wybór produktów

Przeprowadź rygorystyczne testy materiałowe: Przekaż rzeczywiste próbki materiałów do ruidapacking w celu przeprowadzenia testów. Zobacz z pierwszej ręki możliwości przetwarzania sprzętu, dokładność, szybkość i utratę materiału w przypadku konkretnego produktu.

Zaplanuj przyszłe potrzeby produkcyjne: Jeśli w przyszłości będziesz pakować materiały o różnych właściwościach, priorytetem będzie sprzęt kompatybilny lub elastyczny, umożliwiający obsługę różnorodnych produktów.

Zapewnij bezproblemową integrację linii produkcyjnej: Zagwarantuj, że wybrany przez Ciebie sprzęt dozujący będzie płynnie integrował się zarówno z systemami podawania w górnym biegu linii (podnośniki, zasobniki magazynowe), jak i z maszyną pakującą w dolnym biegu linii.

Wydajność meczu: sprawdź zgodność prędkości i interfejsów mechanicznych/fizycznych, aby zapobiec powstawaniu wąskich gardeł.

Priorytetem jest wsparcie i serwis dostawców: Wybierz dostawcę posiadającego duże doświadczenie techniczne i udokumentowaną historię responsywnego, wysokiej jakości serwisu i wsparcia posprzedażowego.

Dzięki starannej ocenie kluczowych właściwości materiału i dogłębnemu zrozumieniu podstawowych zalet i ograniczeń wag wielogłowicowych oraz automatycznych maszyn do liczenia butelek, możesz pewnie wybrać najwłaściwsze, najskuteczniejsze i najbardziej ekonomiczne rozwiązanie dozujące dla Twojej linii pakującej gotowe woreczki.

Potrzebujesz maszyny farmaceutycznej ze szczególnymi potrzebami?

Nasi doświadczeni inżynierowie rozwiążą Twój problem!

Rozwiązania

Skontaktuj się z nami

© 2024 Ruida Packing Machinery Co., Ltd. Wszelkie prawa zastrzeżone. | Polityka prywatności

Przyjazne linki: Bogate pakowanie | Producenci maszyn do napełniania kapsułek