In today’s fast-paced food and pharmaceutical industries, packaging efficiency is no longer just an operational target—it is a decisive factor that determines product quality, cost control, and customer satisfaction. Among various automated packaging systems, the multihead weigher premade pouch packing machine has become one of the most versatile and efficient solutions for handling granular, small-piece, or irregularly shaped products.

However, investing in such advanced equipment requires more than just comparing prices. A good purchasing decision should be guided by a deep understanding of the machine’s technical specifications, its compatibility with your products, and the long-term return on investment. This guide will walk you through the key details you need to consider before purchasing a multihead weigher premade pouch packaging machine.

1. Product Characteristics

The first step in choosing the right packaging machine is to thoroughly understand the nature of your product. Different materials behave differently during weighing and filling.

Material type: Whether your product is granular (tablets, capsules, gummies, nuts), powdery (milk powder), or irregular in shape (dried fruit or candy), it will influence the design of the feeding and weighing system.

Flowability: Products with poor flowability need additional vibration feeders or timing hoppers to ensure stable feeding and accurate weighing.

Moisture and stickiness: Sticky or oily products can cause clumping or residue buildup. To prevent this, consider weighers with Teflon-coated contact surfaces or anti-stick hoppers.

Fragility: For delicate products such as chips or cookies, gentle drop angles and cushioning mechanisms are essential to prevent breakage during filling.

A reliable supplier will typically request product samples for a trial test before recommending the best configuration.

2. Pouch Specifications

The type of bags you use plays a crucial role in choosing the right model. Common options include flat pouches, stand-up pouches (Doypacks), zipper bags, and spout pouches. Each style requires specific handling features.

Please ensure that the machine is suitable for the size range of your packaging bags—including width and length. If your business plans to switch between small snack packs and larger family-size pouches, a model with adjustable bag grippers and changeable forming parts will offer more flexibility.

You should also verify the bag material compatibility. Laminated films such as PET/AL/PE or paper-based materials require different sealing temperatures and pressures. For zipper pouches, confirm that the equipment includes automatic zipper opening, cleaning, and sealing functions.

3. Evaluate the Weigher’s Performance and Configuration

The multihead weigher is the heart of the packaging system. Its design and performance directly determine your weighing accuracy, speed, and product giveaway rate.

Number of heads: The most common configurations are 10, 14, 16, or 20 heads. More heads mean faster operation and greater precision since the machine can combine multiple weight combinations to achieve the target weight.

Accuracy and speed: Typical weighing precision ranges from ±0.1 g to ±1.0 g, depending on the product. A well-tuned system can reach speeds of 40–80 bags per minute, with high-speed models exceeding 100.

Intelligent combination algorithms: Advanced systems automatically calculate the best weight combinations, minimizing waste and ensuring product consistency.

When comparing models, don’t just focus on theoretical speed. Instead, ask for real test results with your actual product and pouch type.

4. Check System Integration and Control

Doypack pouch packing machine rely on seamless communication between different core components. The coordination between the multihead weigher and the premade pouch packaging machine is crucial.

Machines equipped with servo motors offer smoother motion, higher precision, and better synchronization. Look for equipment with a PLC (Programmable Logic Controller) and a touchscreen HMI—ideally from reputable brands such as Siemens or Schneider—for intuitive operation and easier troubleshooting.

If you plan to integrate the system with upstream or downstream equipment—such as conveyors, metal detectors, or checkweighers—ensure the control panel includes compatible communication ports like Ethernet or RS-485.

5. Operation and Maintenance

In continuous production environments, downtime is costly. Therefore, ease of cleaning, maintenance, and changeover should be major considerations.

Select a design that allows tool-free disassembly, especially for hoppers and product-contact parts. Some advanced models offer automatic cleaning modes, using vibration or air-blowing systems to remove product residue between runs.

For food and pharmaceutical applications, insist on stainless steel 304 or 316 contact surfaces to ensure hygiene and corrosion resistance. Additionally, check that the manufacturer provides easy access to spare parts and clear operation manuals or training programs.

6. Examine Sealing and Packaging Quality

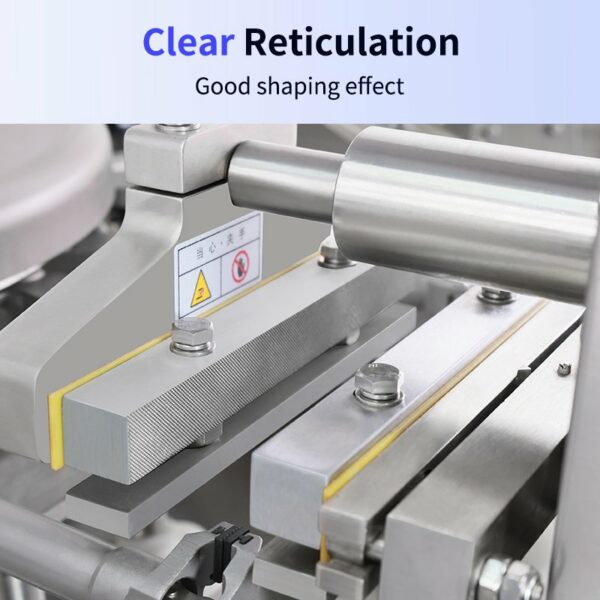

A perfect pouch is the final reflection of your production quality. Poor sealing not only affects appearance but also compromises shelf life.

Your chosen machine should offer precise temperature control (preferably via PID systems) to ensure consistent sealing strength across various film materials. If your product requires air removal or nitrogen flushing, confirm that the equipment supports these optional features.

Optical sensors and mechanical alignment systems are also valuable for ensuring that each pouch is properly positioned before filling and sealing.

7. Safety and Compliance Standards

Never overlook safety and regulatory compliance. The packaging machine should comply with international safety standards such as CE, UL, or GMP.

For food-grade applications, confirm that all product-contact parts are FDA-approved or equivalent.

8. Evaluate the Supplier’s Reliability and Support

A machine is only as good as the company behind it. Ruidapacking offer customization services to tailor the machine to your product and pouch requirements. They also provide on-site installation, operator training, and after-sales technical support.

9. Always Conduct a Trial Test

Finally, before confirming your order, request a trial run at the manufacturer’s facility using your actual product and packaging materials. This allows you to assess:

The real packaging speed and accuracy

The sealing strength and visual appearance of pouches

Ease of cleaning and operation

Power compatibility (220V/380V, 50/60Hz)

A proper test ensures that what you see in the specification sheet matches real-world performance.

Conclusie

Purchasing a multihead weigher premade pouch packing machine is a significant investment—but with careful consideration, it can deliver exceptional long-term value. By paying attention to product compatibility, weigher accuracy, system integration, hygiene standards, and supplier reliability, you can make a well-informed decision that supports your business growth for years to come.

In short, a good packaging machine is not merely a piece of hardware—it’s a strategic asset that transforms how your company brings quality products to market efficiently and professionally.