Jam Blister Verpakkingsmachine

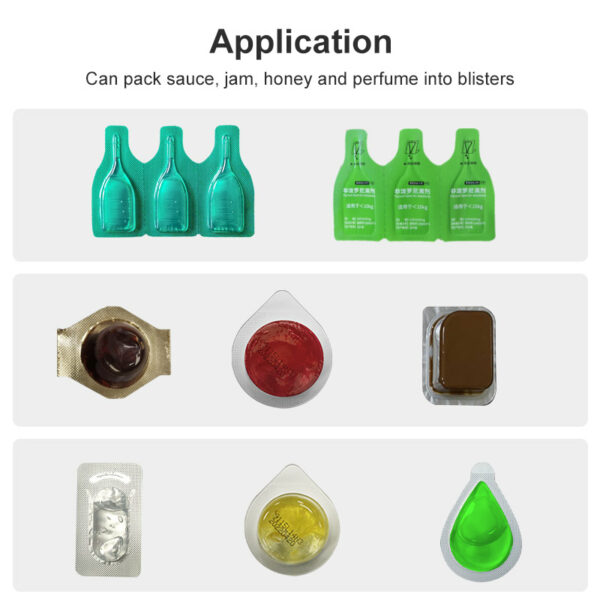

Blisterverpakkingsmachine voor honing met functies zoals volledig automatisch vormen, invoeren, sealen, ponsen, tellen en batchnummercodering. Deze machine kan parfum, jam en honing automatisch sealen in een aluminium-kunststof composiet paneel of aluminium plaat. Een ideale manier om uw product efficiënt en kosteneffectief te verpakken.

Specificatie:

Tot 9.600 blaren/u

Geschikt voor parfum, jam, honing…

Snelle levering binnen 15 dagen

Geschikt voor PVC, PS en PET-materiaal