ハニーブリスター包装機

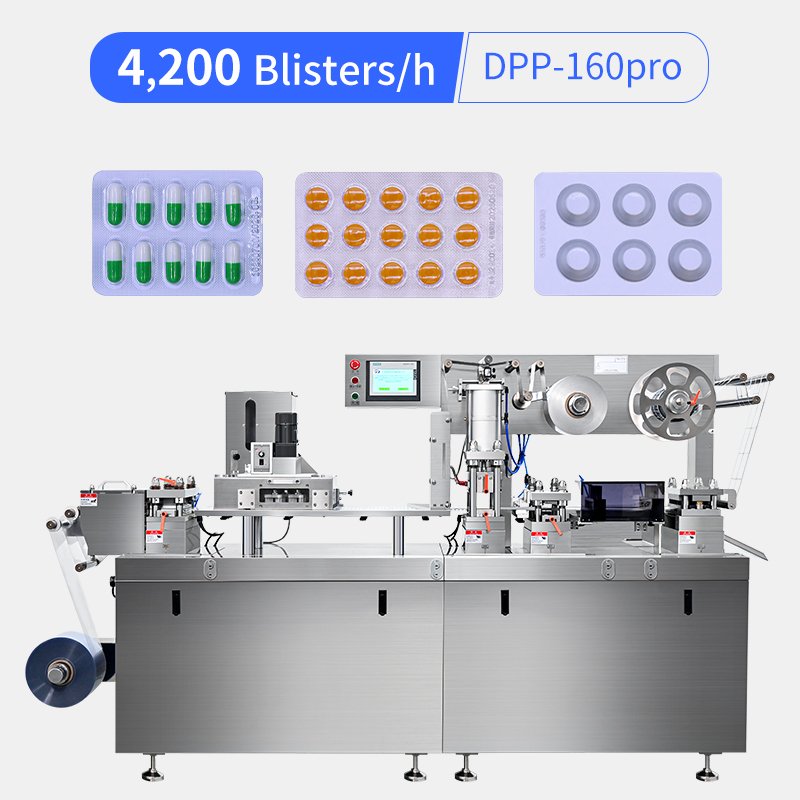

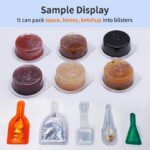

蜂蜜ブリスター包装機は、全自動成形、供給、密封、打ち抜き、計数、バッチ番号コーディングの機能を備えており、香水、ジャム、蜂蜜をアルミニウムプラスチック複合パネルまたはアルミニウム板に自動的に密封できます。

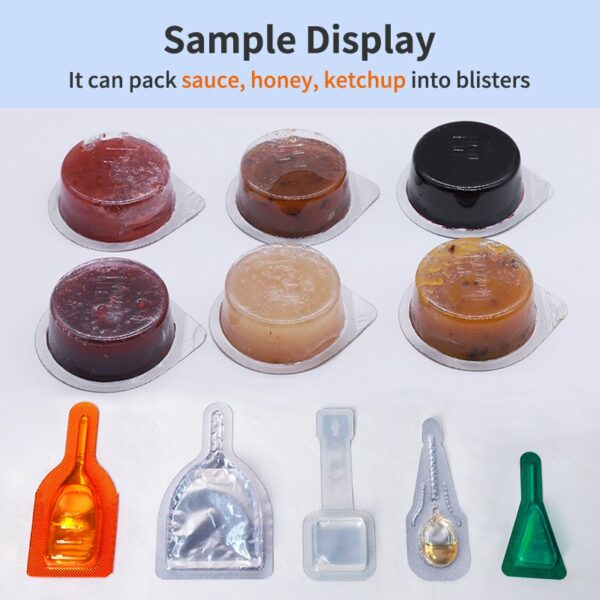

ブリスター形成:機械がフィルムを加熱し、ブリスターの空洞を形成します。この空洞に蜂蜜が閉じ込められます。

蜂蜜の充填:ブリスターが形成されると、蠕動ポンプが液体をブリスター内に注入します。原料の種類に応じて、異なるポンプが選択されます。

密封:蜂蜜を充填した後、上部フィルム(通常はアルミホイル)を広げ、充填されたブリスターの上に被せます。機械が熱と圧力を加えて上部フィルムと下部フィルムを密封し、蜂蜜を気密性の高いブリスターに封入します。

アルミPVCブリスターには液体だけでなく、薬品なども入れることができます。 錠剤カプセルブリスター機.

仕様:

最大9,600ブリスター/時

ジャム、蜂蜜、香水などにも応用可能

15日間の迅速な配送