In the modern pharmaceutical industry, tablet coating is more than just a cosmetic enhancement — it’s a science that protects, perfects, and transforms. High-efficiency coating machines (also known as tablet coaters) play a critical role in ensuring consistent coating quality, improved product performance, and scalable production.

Among all coating techniques, film coating and sugar coating remain the two most widely used processes. While both techniques serve the same purpose of applying a protective layer to tablets, they vary greatly in terms of how they work, where they are used, and how the market adopts them. Recognizing these distinctions enables manufacturers to choose the optimal coating approach and enhance overall production performance.

1. Principio di funzionamento

1.1. Film Coating

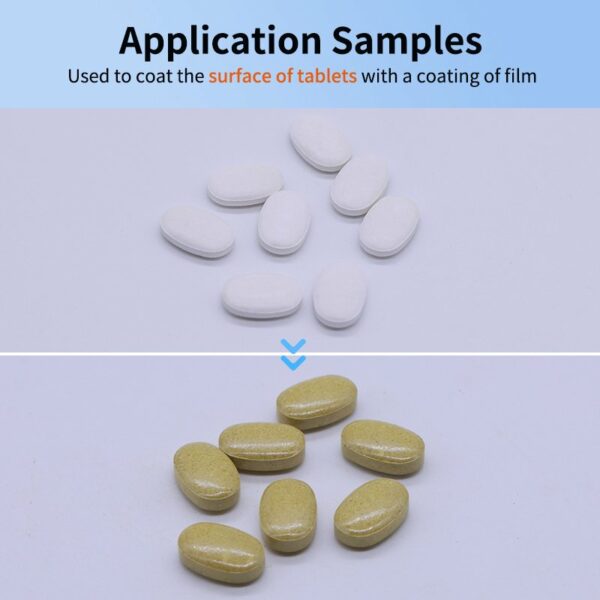

Film coating is a thin polymer-based coating process in which a solution or suspension containing film-forming polymers, plasticizers, and pigments is sprayed onto rotating tablets inside a perforated coating drum.

As the hot air passes through the tablet bed, the solvent evaporates, leaving behind a uniform, thin, and smooth film layer on each tablet. The process is controlled by precise parameters such as spray rate, inlet air temperature, atomizing pressure, and drum speed.

Modern high-efficiency film coating machines, integrate advanced systems for automatic temperature control, adjustable spray guns, and optimized air circulation, ensuring consistent coating quality even at large production scales.

Key features of film coating

Thin, smooth coating layer (typically 20–100 microns)

Short coating time

Precise process control

Minimal material waste

Compatible with moisture-sensitive or heat-sensitive tablets

1.2. Sugar Coating

Sugar coating, on the other hand, is the classic technique that has been used for decades in the pharmaceutical and confectionery industries. In this process, tablets are coated with multiple layers of syrup (sugar solution) and other excipients such as colorants, opacifiers, and polishing agents.

The process involves several stages — sealing, subcoating, smoothing, coloring, and polishing — each requiring time and skill. The tablets gradually gain weight and volume as the sugar layers build up.

While modern equipment automates much of the process, sugar coating still demands longer processing times and higher material consumption compared to film coating. However, it produces tablets with an appealing glossy appearance and pleasant taste, which are desirable in certain product categories.

Key features of sugar coating:

Thick, shiny, and colorful coating

Longer production cycle

Excellent taste masking

Traditional and visually appealing finish

2. Application Scenarios

2.1. Film Coating

Film coating has become the standard coating method for most modern pharmaceutical and nutraceutical products. It offers strong protection and precise functionality while maintaining production efficiency.

Typical applications include:

Functional coating (controlled-release, enteric coating, moisture barrier)

Herbal and nutraceutical supplements

Tablets requiring rapid coating and high throughput

Film coating is ideal for manufacturers who aim for high productivity, lower costs, and compliance with cGMP standards. The coating process can be smoothly expanded from small-scale trials to full-scale manufacturing, maintaining uniform quality from one batch to the next.

2.2. Sugar Coating

Although film coating dominates today’s market, sugar coating still holds its ground in certain niches. Its aesthetic appeal and taste-masking properties make it popular in nutraceutical, herbal, and pediatric formulations, as well as in markets where consumer preference favors traditional or glossy tablets.

Typical applications include:

Chewable or flavored tablets

Herbal and traditional medicine

Dietary supplements

Decorative or brand-differentiated products

In addition, some companies use sugar coating to preserve brand identity — associating the glossy appearance with heritage, quality, and consumer trust.

3. Performance Comparison: Efficiency, Cost, and Quality

| Aspect |

Rivestimento in pellicola |

Rivestimento di zucchero |

| Spessore del rivestimento |

20–100 µm |

0.5–1 mm |

| Process Time |

1–2 hours |

8–24 hours |

| Weight Gain |

2–3% |

30–50% |

| Costo del materiale |

Inferiore |

Più alto |

| Efficienza produttiva |

Alto |

Basso |

| Aspetto |

Smooth, matte or glossy |

Bright, glossy |

| Mascheramento del gusto |

Moderare |

Eccellente |

| Functional Coating |

Possible (enteric, sustained-release) |

Limitato |

| Market Trend |

Growing rapidly |

Declining but stable niche |

4. Market Trends

In recent years, film coating has become the global standard, driven by its efficiency, scalability, and environmental benefits. Pharmaceutical companies are moving away from sugar coating due to its long process time, higher labor cost, and lack of functional performance.

Key market trends include:

Automation and digitization: Modern high-efficiency coating machines feature intelligent control systems, real-time monitoring, and recipe management for stable, repeatable results.

Sustainability: Film coating uses less water and energy, aligning with green manufacturing initiatives.

Functional innovation: The rise of enteric coatings, controlled-release systems, and multi-layer coatings expands the role of film coating beyond aesthetics.

Global compliance: Film coating technology meets cGMP, FDA, and EU regulatory standards, supporting international market access.

Meanwhile, sugar coating remains valuable in niche sectors, particularly where consumer experience, color richness, or flavor are marketing priorities — for example, in traditional herbal medicine markets in Asia or in children’s supplements.

5. Choosing the Right Tablet Coating Machine

Selecting the right coating technology depends on the product formulation, target market, and production goals.

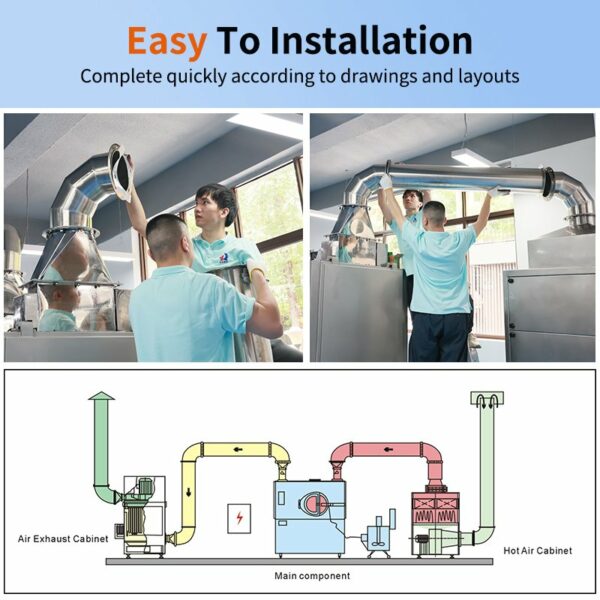

Modern high-efficiency coating machines like those produced by Ruidapacking offer flexibility for both film and sugar coating applications. Equipped with:

Advanced spray systems ensuring uniform coating

Optimized air circulation for fast drying

Intelligent temperature and humidity control

CIP (Cleaning-In-Place) systems for easy maintenance

These features help manufacturers achieve superior coating quality while minimizing downtime and production waste.

The RD-HGBY-80 high-efficiency coater is engineered for pharmaceutical, nutraceutical, and food applications, delivering coating solutions that balance high speed, accuracy, and flexibility. Whether your goal is to enhance tablet appearance or develop functional coatings, we’re offers reliable technology tailored to your needs.

6. Conclusion

Film coating and sugar coating represent two eras of tablet coating technology — one defined by efficiency and function, the other by artistry and tradition.

While film coating leads the modern market with its speed, precision, and sustainability, sugar coating continues to shine in niche applications that value aesthetics and taste.

For manufacturers, the right choice depends on the balance between production efficiency and market preference. And with the evolution of high-efficiency coating machines, it’s now possible to master both — preserving the beauty of the past while embracing the innovation of the future.