Macchina confezionatrice per blister di miele

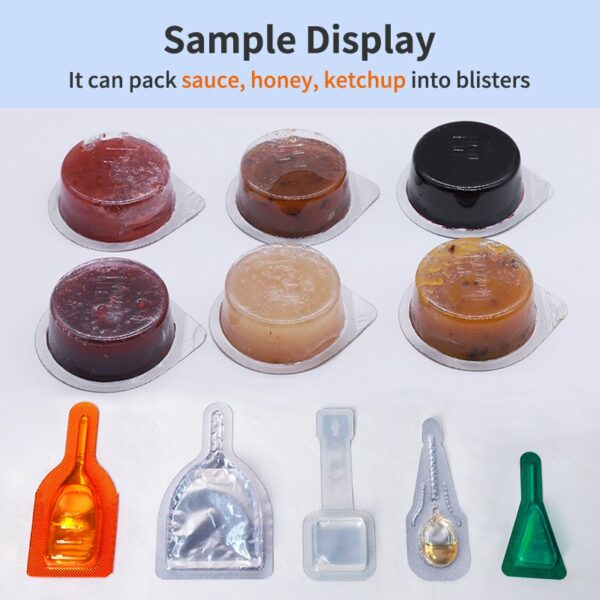

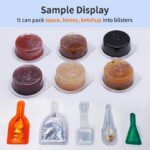

Confezionatrice blister per miele con funzioni completamente automatiche di formatura, alimentazione, sigillatura, punzonatura, conteggio e codifica del numero di lotto. Può sigillare automaticamente profumi, marmellate e miele in un pannello composito di alluminio-plastica o in una piastra di alluminio.

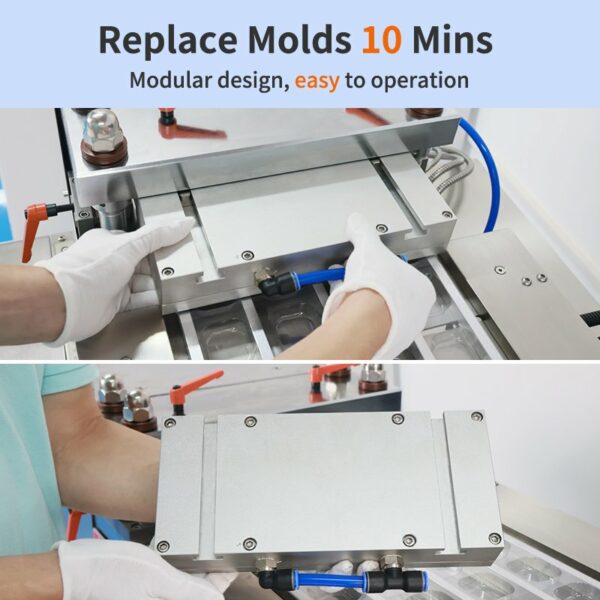

Formazione di blister: la macchina riscalda e forma le cavità per i blister nella pellicola. Queste cavità conterranno il miele.

Riempimento del miele: una volta formate le vesciche, la pompa peristaltica inietta il liquido al loro interno. Le pompe vengono selezionate in base alle diverse materie prime.

Sigillatura: Dopo il riempimento, una pellicola superiore, spesso un foglio di alluminio, viene srotolata e posizionata sopra i blister riempiti. La macchina applica quindi calore e pressione per sigillare la pellicola superiore a quella inferiore, racchiudendo il miele in blister ermetici.

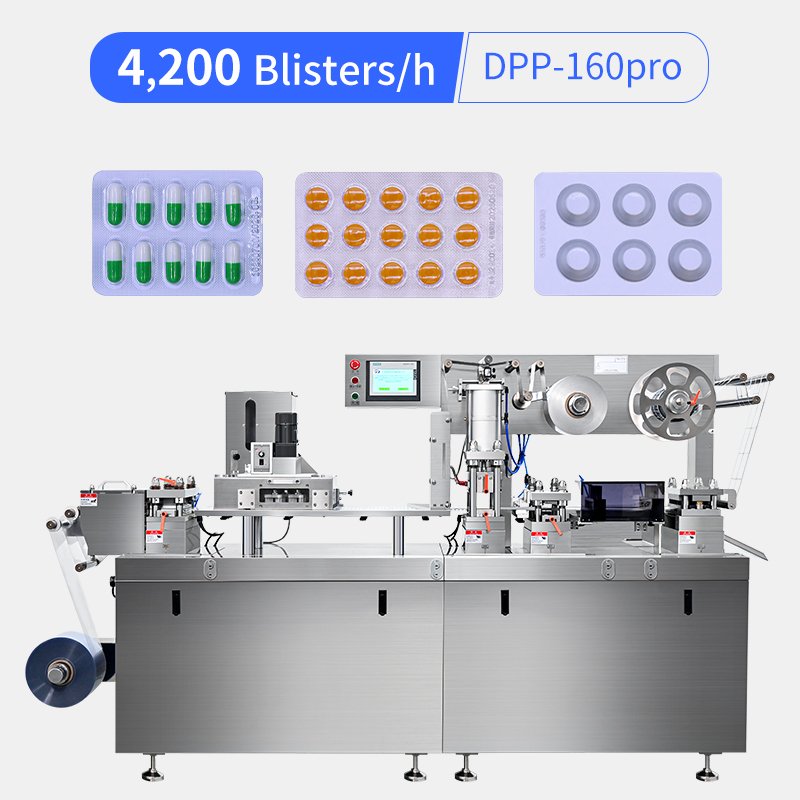

Nel blister in alluminio-pvc non possono essere inseriti solo liquidi, ma anche medicinali, come macchina blister per capsule e compresse.

Specifica:

Fino a 9.600 blister/h

Applicabile per marmellata, miele, profumo…

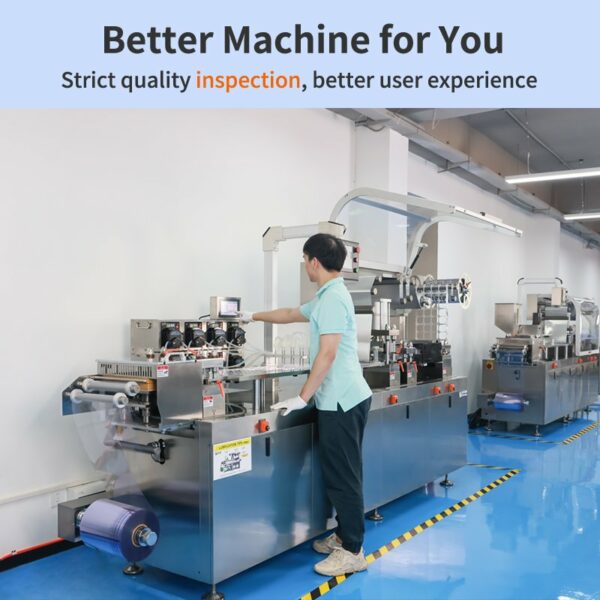

Consegna rapida in 15 giorni