In pharmaceutical and nutraceutical manufacturing, dosage accuracy isn’t just a metric—it’s a regulatory imperative. cGMP (current Good Manufacturing Practice) guidelines enforced by the FDA, EMA, and ICH mandate strict uniformity in drug products. Per USP General Chapter <905> “Uniformity of Dosage Units,” oral solid dosage forms must achieve acceptance values (AV) ≤15.0—translating to ≤5% variability for critical APIs. For high-potency drugs (hormones, cytotoxins), deviations beyond ±2% risk therapeutic failure or toxicity, making precision machinery non-negotiable.

The automatic capsule filling machine for liquid meets—and exceeds—these standards through a synchronized electro-mechanical system engineered for zero-compromise accuracy:

1. cGMP’s Precision Mandate: Why ±1-2% Matters

Temperature-sensitive biologics (peptides, live probiotics) degrade with overfilling.

Underfilled lipid-based drugs (isotretinoin) compromise bioavailability.

±2% tolerance ensures batch-to-batch consistency, eliminating QA rejections per 21 CFR 211.110.

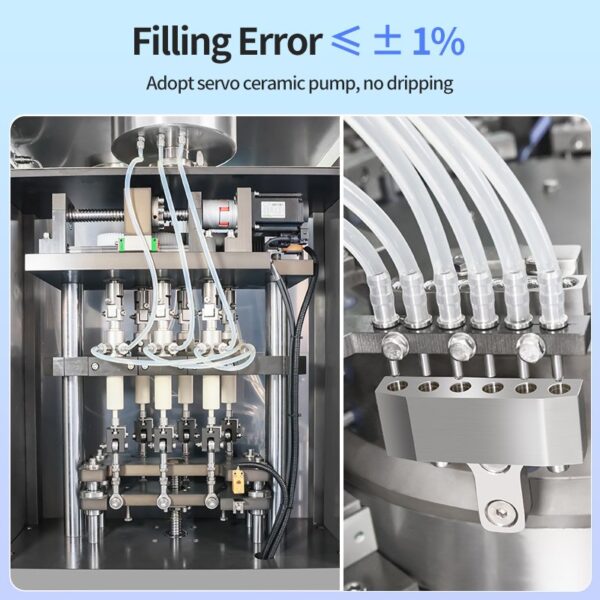

2. The Core Precision Triad: Ceramic Pumps + Dual Servo Synergy

Japan Yaskawa Ceramic Dosing Pumps

Engineered with 0.1-µm surface roughness (vs. stainless steel’s 1.5µm) to prevent material adhesion.

Chemically inert zirconia construction resists corrosion from acids/alkalis (pH 1–14).

Maintains viscosity stability for shear-sensitive fluids (0.5–3,000 cP).

Dual Schneider Electric Lexium 32 Servo Motors

Motor A (Fill Control)

Governs piston displacement with 0.001mm resolution, digitally adjusting volume per capsule weight feedback.

Compensates for density changes in suspensions (40% solid-content probiotics).

Motor B (Anti-Drip & Retraction)

Executes 5ms reverse suction post-fill, creating negative pressure to retract droplets.

Prevents cross-contamination and capsule seal failure from residual liquid.

Environmental Stability Assurance

Temperature-controlled filling zone (±0.5°C) prevents thermal expansion/contraction of liquids.

Vibration-dampened mounts isolate pumps from machine oscillations.

Industry Impact: From Compliance to Competitive Edge

A major EU nutraceutical manufacturer reduced liquid capsule batch rejections from 12% to 0.3% after adopting the NJPL-330C—saving €380,000/year in wasted APIs. For injectable-grade fish oil encapsulation, ±1.5% accuracy enabled ICH Q3D elemental impurity compliance without over-engineering formulations.

“Precision isn’t a luxury—it’s the bedrock of patient safety. The NJPL-330C’s servo-ceramic architecture sets the new GMP benchmark.” — Dr. Elena Vogt, Pharmaceutical Manufacturing Consultant

Certified Precision: Validated per ASTM E2709/E2810 standards with 3x consecutive 0.98% RSD (Relative Standard Deviation).

Key Takeaways for Quality Directors

Regulatory Defense: Full electronic records (ERP integration) satisfy FDA 21 CFR Part 11.

Cost Control: ±1% accuracy = 7–9% API savings vs. volumetric fillers.

Zero Contamination: Anti-drip servos reduce cleaning validations by 30%.

Ruidapacking also offers complete back-end packaging solutions. For example, for packaging liquid capsules into aluminum-plastic blisters, macchine per il confezionamento in blister can meet your packaging needs. From the DPP-90R to the DPH-270Max, we offer a wide range of models, covering small, medium, and large production volumes. For packaging liquid capsules into bottles, a multi-capsule bottling line is the best choice. With 60 capsules per bottle as the standard, the RD-SLL-16H can produce up to 100 bottles per minute. Back-end cartoners, case packers, and palletizers are also available.