- Heim

- Kapselfüllmaschine

- Halbautomatische Kapselfüllmaschine

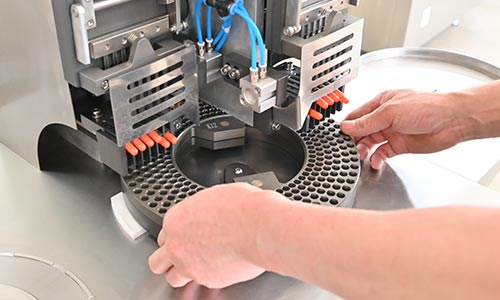

Halbautomatische Kapselfüllmaschine

Die Herstellung einer halbautomatischen Kapselfüllmaschine erfordert die Unterstützung eines Bedieners, indem er die Füllplatten zwischen den verschiedenen Abschnitten im Prozess bewegt. Das ist kostengünstiger und benutzerfreundlicher.

Geeignete Kapselgrößen:

|  |  |  |  |  |  |  | |

| Kapselgröße | #000 | #00 | #0 | #1 | #2 | #3 | #4 | #5 |

| Gesperrte Länge | 26,14 mm | 23,30 mm | 21,7 mm | 19,4 mm | 18,0 mm | 15,9 mm | 14,3 mm | 11,1 mm |

| Kapselvolumen | 1,37 ml | 0,91 ml | 0,68 ml | 0,5 ml | 0,37 ml | 0,3 ml | 0,21 ml | 0,13 ml |

(Die Füllmenge kann aufgrund unterschiedlicher Pulverzusammensetzungen variieren.)

Funktionsweise einer halbautomatischen Kapselfüllmaschine?

Das komplette Sortiment an halbautomatischen Kapselfüllmaschinen

Halbautomatische Kapselfüllmaschine

Halbautomatische Kapselfüllmaschine kann Pulver, Granulat, Pellets und Flüssigkeit in Hartkapseln füllen, geeignet für Kapselgröße ...

| Modell | CGN-208 | CGNT-209 |

| Ausgabe | 28.000 Stück/h | 40.000 Stück/h |

| Anwendbare Kapsel | 000#, 00#, 0#, 1#, 2#, 3#, 4#, 5# | |

| Stromversorgung | 2,12 kW | 2,2 kW |

| Leistung | 380/220 V 50 Hz (anpassbar) | |

| Nettogewicht | 400 kg | 405 kg |

| Packmaß | 1640*720*1700 mm | 1640*720*1700 mm |

Eine kluge Investition für die Pharmaindustrie

Einfach zu verwenden

Kostenfreundlich

Genau

Sicher im Betrieb

Keine Umweltverschmutzung

Wir unterstützen Sie mit umfassendem Service

Lebenslange Garantie

Schnelle Lieferung in 7 Tagen

24/7 Online-Service

Häufig gestellte Fragen

- Schmieren Sie die Nocke regelmäßig, um sie in gutem Zustand zu halten.

- Demontieren und reinigen Sie die Füllstation, um überschüssiges Material zu entfernen und so Verstopfungen und Rost nach Abschluss der Produktion zu verhindern.

- Geben Sie der Vakuumpumpe regelmäßig Schmieröl hinzu und reinigen Sie sie vom Staub.

- Füllen Sie regelmäßig ausreichend Wasser über die Hälfte des Fasskörpers in den Wassertank.

Funktionsprinzip der halbautomatischen Kapselfüllmaschine

Eine halbautomatische Kapselfüllmaschine vereinzelt leere Kapseln, füllt sie mit dem gewünschten Material und verschließt sie.

Es umfasst die folgenden Schritte:

- Kapseltrennung

- Tankstellenaufbau

- Füllen des Hopperials

- Ausrichtung und Orientierung der Kapseln

- Dosisanpassung

- Befüllen der Kapseln

- Kapselverschluss

- Auswerfen der gefüllten Kapseln

Automatische vs. halbautomatische Kapselfüllmaschine

Automatische Kapselfüllmaschine

Vorteile:

Automatische Maschinen ermöglichen eine Hochgeschwindigkeitsproduktion und füllen Kapseln schnell und effizient, was für die Produktion im großen Maßstab von Vorteil ist.

Sie erfordern nur minimale manuelle Eingriffe, wodurch der Bedarf an umfangreicher menschlicher Arbeit reduziert und die Produktivität gesteigert wird.

Automatische Maschinen sind für eine präzise Dosierung ausgelegt und gewährleisten eine gleichmäßige und genaue Befüllung der Kapseln.

Sie verfügen häufig über zusätzliche Funktionen wie Kapselsortierung, automatische Kapselausrichtung und Online-Inspektionssysteme, wodurch die allgemeine Betriebseffizienz verbessert wird.

Nachteile:

Automatische Maschinen weisen im Vergleich zu halbautomatischen Maschinen tendenziell höhere Anschaffungskosten auf und stellen daher eine erhebliche Investition dar.

Aufgrund der Komplexität automatischer Maschinen können für den Betrieb und die Wartung dieser Maschinen spezielle Schulungen und technisches Fachwissen erforderlich sein.

Bei der Kleinserienproduktion oder bei häufigen Produktwechseln können diese Maschinen an ihre Grenzen stoßen.

Automatische Maschinen sind im Allgemeinen größer und benötigen mehr Platz in der Produktionsanlage.

Halbautomatische Kapselfüllmaschine

Vorteile:

Halbautomatische Maschinen sind im Allgemeinen kostengünstiger und daher eine sinnvolle Option für kleinere Hersteller oder Startups mit begrenztem Budget.

Sie bieten mehr Flexibilität hinsichtlich der Produktionsvielfalt und ermöglichen eine einfachere Anpassung an kleine oder vielfältige Produktlinien.

Halbautomatische Maschinen sind relativ einfacher zu bedienen und erfordern weniger technisches Fachwissen, was eine einfachere Schulung und Wartung ermöglicht.

Diese Maschinen sind normalerweise kleiner und nehmen im Produktionsbereich weniger Platz ein.

Nachteile:

Halbautomatische Maschinen erfordern mehr manuelle Handhabung und sind mit der Einbindung von Bedienern in den Kapselfüllvorgang verbunden. Dies kann zeitaufwändig sein und zu Fehlern führen.

Die Füllgeschwindigkeit wird durch die manuelle Handhabung begrenzt, was im Vergleich zu automatischen Maschinen zu langsameren Produktionsraten führt.

Aufgrund der manuellen Durchführung des Prozesses kann es zu leichten Abweichungen bei der Füllgenauigkeit oder der Kapselqualität kommen.

Einige halbautomatische Maschinen sind möglicherweise weniger langlebig oder neigen häufiger zu Ausfällen als ihre automatischen Gegenstücke.