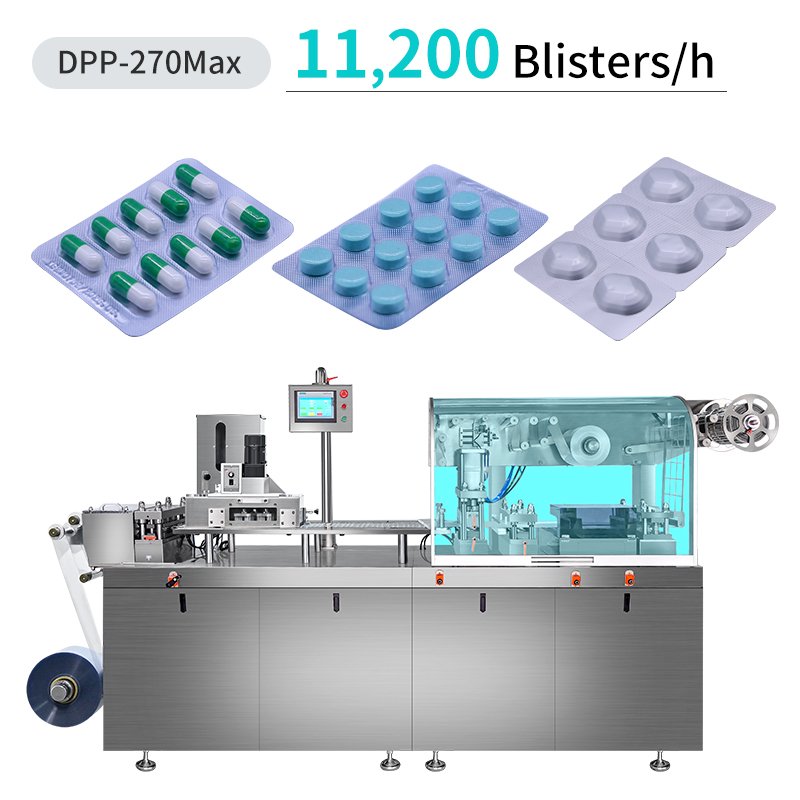

High speed tablet compression machine (typically rotary press capable of producing hundreds of thousands of tablets per hour) ensure consistent tablet quality through weight of each tablet is ensured by monitoring the pressure of each punch in real time. The core objective is to maintain uniformity in weight, thickness, hardness, and disintegration for every tablet—even at high production speeds. Below are the key technologies and measures that make this possible.

1. Precision Mechanical Design

A robust mechanical foundation is essential—no control system can compensate for poor hardware.

Multi-Tooling Rotary System

The tablet press use multiple sets of punches and dies (26, 32, or 40 stations) arranged in a circular configuration. As the turret rotates, each station sequentially performs filling, compression, and output. High-precision machining ensures uniform dimensions and minimal clearance between punches and dies, reducing mechanical variability.

Pre-Compression and Main Compression

Nén trước: Eliminates air pockets in the powder, minimizing capping and laminating—especially critical for complex formulations.

Main compression: Delivers the final pressure. Main press wheel ensure smooth, even force distribution, preventing punch breakage.

Filling and Output Mechanisms

Precision feeders ensure consistent, segregation-free powder flow into die cavities.

Smooth output guides prevent tablet damage during discharge.

2. Advanced Automation & Control Systems

Modern high-speed tablet making machine rely on automation for real-time adjustments.

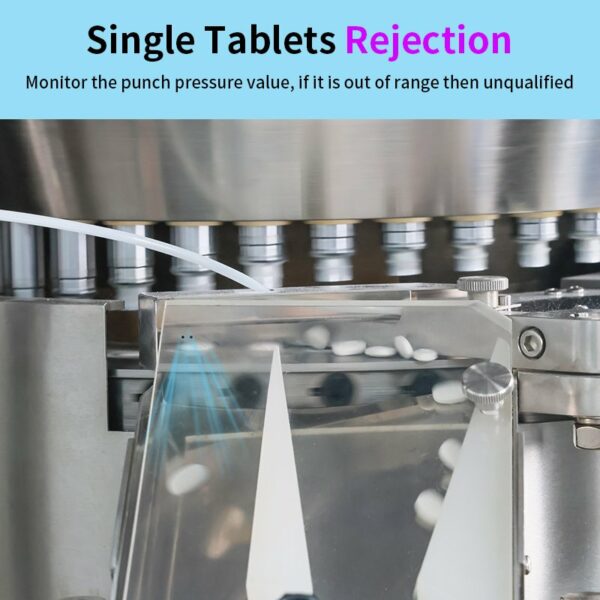

Pressure Sensors & Closed-Loop Control

The pressure sensor on the main press wheel monitors the pressure on each punch.

How it works: The system compares real-time pressure readings against a target value. If pressure is too high (indicating excess fill depth), the system reduces it automatically—and vice versa.

This closed-loop feedback operates in milliseconds, ensuring uniform hardness and thickness.

Weight Control

Since tablet weight correlates with pressure (assuming consistent powder flow), controlling pressure indirectly regulates weight.

Some advanced models include in-line weighing systems for periodic verification and fine-tuning.

Servo Motor Drive Technology

Traditional presses use mechanical clutches, which can cause shock and over-compression during speed changes.

High speed tablet machine employ servo motors for precise turret positioning, acceleration, and deceleration. This enables “soft starts” and “soft stops,” reducing mechanical stress and protecting tooling.

Process Analytical Technology (PAT) & Data Logging

Human-machine interfaces (HMIs) display real-time metrics like pressure, production rates, and weight deviations.

Compliant with cGMP, all data is traceable for audits.

Advanced systems use machine learning (ML) for predictive maintenance and process optimization.

3. Powder Material Requirements

Even the best tablet press cannot produce quality tablets from poor-quality powder.

Flowability

Powders must flow uniformly into dies. Granulation (wet, dry, or fluidized bed) or glidants (colloidal silica) can improve flow.

Compressibility

The blend must form stable tablets under pressure. Excipients like microcrystalline cellulose or lactose enhance compactibility.

Particle Size Distribution

Uniform particle size prevents segregation during handling, ensuring content uniformity.

4. Strict Operational & Maintenance Protocols

Tooling Management

High-wear-resistant tooling (premium steel) must be inspected and replaced regularly to maintain tablet dimensions.

Cleaning & Maintenance

Regular cleaning prevents cross-contamination and residue buildup.

Critical moving parts require lubrication to sustain precision.

Setup & Process Validation

Pre-production calibration (fill depth, pressure, speed) must meet IQ/OQ/PQ standards.

Conclusion

High speed tablet presses achieve consistent quality by:

Hardware: Precision-machined components parts.

Control: Real-time pressure monitoring controlling the stability of tablet weight.

Drive: Servo motors for smooth, precise operation.

Management: AT-driven monitoring, traceability, and strict maintenance.

Ultimately, this combination of innovations transforms the tablet press process into a digitally controlled, data-driven operation, enabling the production of high-quality tablets at astonishing speeds.