Máy đóng gói vỉ phẳng DDP

Máy đóng gói vỉ phẳng DDP được thiết kế để đóng gói viên nén, viên nang và các sản phẩm dược phẩm dạng rắn khác. Máy hoạt động dựa trên sự kết hợp của nhiệt, áp suất và chuyển động cơ học để tạo hình, làm đầy và niêm phong vỉ thuốc.

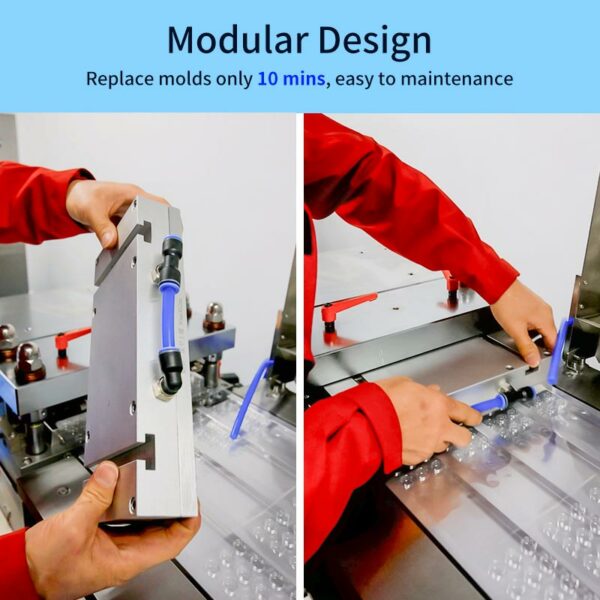

Quá trình tạo hình: Màng phim được nung nóng được kéo vào một bộ khuôn bằng tác động chân không, tạo thành các vỉ. Các khuôn xác định hình dạng và độ sâu của vỉ.

Chiết rót: Sau khi vỉ được hình thành, các sản phẩm (viên nén, viên nang, v.v.) được đặt vào các túi đã hình thành.

Niêm phong: Vỉ đã tạo hình và làm đầy sau đó được đưa qua trạm niêm phong, tại đây nhiệt độ và áp suất được sử dụng để liên kết lớp màng nắp với lớp màng nhựa.

Đục lỗ & Cắt: Sau khi niêm phong, máy có thể đục lỗ để tạo ra từng vỉ riêng lẻ hoặc cắt dải vỉ liên tục thành từng gói riêng lẻ.

Đặc điểm kỹ thuật:

Lên đến 11.200 vỉ/giờ

Áp dụng cho viên nén, viên nang và thuốc lá điện tử

Phù hợp với vật liệu PVC、PS、PET