Giới thiệu

Vitamin và kẹo dẻo chức năng đang bùng nổ, nhưng nhiều nhà máy phát hiện ra rằng nút thắt cổ chai thực sự của họ không phải là quá trình nấu chảy hay đúc kẹo dẻo – mà là việc đếm và đóng chai chúng một cách chính xác với tốc độ cao. A Máy đếm kẹo dẻo Nằm ở trung tâm của đoạn đường dây này. Nếu máy không thể xử lý các viên kẹo dẻo dính và không đều, bạn sẽ nhanh chóng gặp phải các vấn đề như đếm sai, vón cục, phải làm lại và thời gian ngừng hoạt động. Hướng dẫn này giải thích máy đếm kẹo dẻo là gì, sự khác biệt giữa máy đếm kẹo dẻo và máy đếm viên nén/viên nang, các thiết kế chống vón cục và thông số kỹ thuật quan trọng nào thực sự cần thiết, cũng như cách các loại nhà máy khác nhau – từ startup đến thương hiệu đã thành lập và nhà sản xuất hợp đồng – có thể lựa chọn giải pháp phù hợp cho dây chuyền đóng gói kẹo dẻo của mình.

1. Tại sao Máy đếm kẹo dẻo lại quan trọng vào thời điểm này?

Thực phẩm bổ sung dạng kẹo dẻo Đã trở thành dạng bào chế phổ biến cho vitamin, khoáng chất và các thành phần chức năng. Người lớn và trẻ em đều ưa thích hương vị và kết cấu của chúng, và các thương hiệu liên tục ra mắt các hương vị và hình dạng mới mỗi năm. Đồng thời, các cơ quan quản lý và nhà bán lẻ vẫn yêu cầu liều lượng chính xác và bao bì sạch sẽ, tuân thủ quy định.

Việc đếm thủ công hoặc sử dụng máy đếm kẹo thông thường không thể đáp ứng được các yêu cầu này khi khối lượng và số lượng biến thể sản phẩm tăng lên. Một máy đếm kẹo dẻo chuyên dụng và, trong nhiều trường hợp, một dây chuyền đếm và đóng chai hoàn chỉnh là cần thiết để:

- Kiểm soát chính xác số lượng sản phẩm trong mỗi chai.

- Chạy nhiều sản phẩm khác nhau mà không mất quá nhiều thời gian chuyển đổi.

- Giữ nguyên sản lượng khi xử lý các sản phẩm dính, mềm.

2. Máy đếm kẹo dẻo là gì?

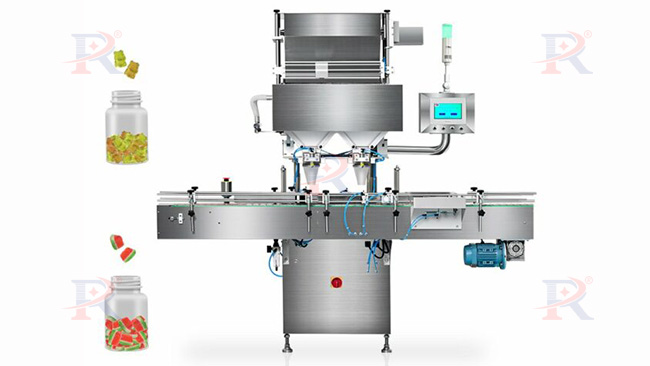

Máy đếm kẹo dẻo là một thiết bị đếm điện tử có khả năng tách riêng từng viên kẹo dẻo, phát hiện và đếm chúng, sau đó giải phóng số lượng mục tiêu vào từng chai hoặc lọ. Thiết bị này thường được đặt giữa Máy sắp xếp chai và máy chèn chất hút ẩm trên một Dây chuyền đóng chai kẹo dẻo.

2.1 Sự khác biệt so với máy đếm viên nén và viên nang

Máy đếm viên nén và viên nang được thiết kế cho các chất rắn không dính, đồng nhất. Kẹo dẻo có hành vi rất khác biệt:

- Chúng mềm mại và đàn hồi, thường được phủ một lớp đường, dầu hoặc bột chua.

- Kích thước và hình dạng có sự biến đổi lớn hơn so với các viên thuốc tiêu chuẩn.

- Họ thường tụ tập với nhau.

Do đó, một máy có thể hoạt động hoàn hảo với viên nén có thể dễ dàng bị tắc nghẽn hoặc đếm sai khi sử dụng kẹo dẻo. Máy đếm kẹo dẻo cần có tính năng chống dính.

2.2 Các thành phần chính và vị trí đường dây

Hầu hết các máy đếm kẹo dẻo bao gồm:

- Một phễu và bộ cấp liệu.

- Các kênh rung giúp phân tán kẹo dẻo.

- Một phần đếm sử dụng cảm biến quang điện hoặc camera.

- Ống dẫn hoặc vòi phun để hướng các viên kẹo dẻo đã đếm vào chai.

- Hệ thống điều khiển đồng bộ với quy trình xử lý chai.

Trong một dây chuyền sản xuất tiêu chuẩn, chai lọ được sắp xếp lại, định vị dưới các vòi phun, được đổ đầy bởi máy đếm kẹo gấu, sau đó được chuyển sang công đoạn chèn chất hút ẩm, đóng nắp, hàn kín bằng cảm ứng, dán nhãn và in mã.

3. Các loại máy đếm kẹo dẻo

Khi so sánh các thiết bị đếm kẹo dẻo, việc xem xét từ hai khía cạnh sau sẽ hữu ích: mức độ tự động hóa và công nghệ đếm mà thiết bị sử dụng.

3.1 Bán tự động so với Tự động hoàn toàn

Máy đếm kẹo dẻo bán tự động Kết hợp đếm điện tử với thao tác thủ công hoặc đơn giản trên chai. Người vận hành đặt chai dưới vòi phun, khởi động chu trình và lấy chai đã được đổ đầy. Cấu hình này phù hợp cho các phòng thí nghiệm, startup và các đơn hàng nhỏ, nơi khối lượng sản xuất không lớn và tính linh hoạt quan trọng hơn tốc độ.

Máy đếm kẹo dẻo tự động hoàn toàn Được tích hợp vào hệ thống băng tải. Chai được vận chuyển, định vị và đồng bộ hóa với chu kỳ đếm mà không cần can thiệp thủ công. Đây là lựa chọn tiêu chuẩn cho các thương hiệu thực phẩm chức năng trung bình và lớn cũng như các nhà sản xuất gia công cần năng suất cao hơn và hiệu suất hoạt động tổng thể (OEE) ổn định.

3.2 Công nghệ đếm

Hầu hết các máy đếm kẹo dẻo đều sử dụng các kênh rung động kết hợp với cảm biến quang điện. Dao động giúp phân tán kẹo dẻo thành một lớp duy nhất, và các cảm biến sẽ phát hiện từng viên kẹo khi chúng đi qua một điểm đã được định trước.

Các hệ thống tiên tiến hơn sử dụng công nghệ đếm dựa trên hình ảnh, trong đó camera quét các viên kẹo dẻo trên băng tải hoặc đĩa, và phần mềm thực hiện việc đếm. Các thiết bị đếm dựa trên hình ảnh có thể xử lý các màu sắc và hình dạng hỗn hợp, đồng thời có thể phát hiện các viên kẹo bị biến dạng hoặc hỏng, nhưng chúng có giá thành cao hơn và yêu cầu vệ sinh và hiệu chuẩn cẩn thận để duy trì hiệu suất.

4. Các yếu tố quan trọng trong việc lựa chọn và Thông số kỹ thuật Người mua nên tập trung vào

Không phải mọi thông số trên bảng dữ liệu hoặc báo giá đều có tầm quan trọng như nhau. Các thông số kỹ thuật và yếu tố lựa chọn sau đây thường có ảnh hưởng lớn nhất đến quá trình sản xuất thực tế.

4.1 Thiết kế chống dính

Kẹo dẻo dính là nguyên nhân chính gây tắc nghẽn và đếm sai. Vì vậy, cách máy xử lý tình trạng vón cục là rất quan trọng. Hãy tìm:

- Bộ khuấy có gai cho phễu

Giúp làm tan các cục trước khi chúng đi vào các kênh rung, để kẹo dẻo đến dưới dạng các mảnh rời thay vì các cục lớn.

- Hệ thống chống vón cục

Giữ cho sản phẩm di chuyển trong dòng chảy có kiểm soát, giảm thiểu nguy cơ hình thành các cầu trong các kênh.

- Tấm panel có vết lõm làm từ Teflon

Các tấm panel có vết lõm làm từ Teflon (PTFE) giúp giảm diện tích tiếp xúc và ma sát bề mặt, do đó các viên kẹo dẻo trượt dễ dàng.

- Cổng xả được phủ PTFE

Giúp kẹo dẻo rơi vào chai một cách gọn gàng.

Quầy kẹo dẻo của Ruidapacking Kết hợp các thành phần chống vón cục này để giữ cho các viên kẹo dẻo dính chảy mượt mà, giúp giảm đáng kể tình trạng kẹt và dừng máy không mong muốn trong quá trình sản xuất thực tế.

4.2 Đầu ra và Tốc độ

Nhà sản xuất thường tập trung vào số chai tối đa mỗi phút, nhưng tốc độ hiệu quả mới là yếu tố quan trọng hơn. Hãy xem xét:

- Sản lượng hàng ngày và hàng tháng bắt buộc.

- Số lượng sản phẩm khác nhau và số lần thay đổi sản phẩm trong mỗi ca làm việc.

- Thời gian dừng thông thường để kiểm tra và vệ sinh.

Một máy móc hoạt động chậm hơn một chút nhưng ổn định hơn có thể sản xuất được nhiều chai bán được hơn mỗi ca làm việc so với một mô hình tốc độ cao lý thuyết nhưng thường xuyên bị kẹt.

4.3 Độ chính xác của việc đếm

Độ chính xác có ảnh hưởng trực tiếp đến cả chi phí và tuân thủ quy định. Việc đổ quá mức tích lũy qua hàng triệu chai; việc đổ thiếu gây ra khiếu nại và rủi ro tuân thủ quy định. Yêu cầu các số liệu độ chính xác đã được chứng minh với sản phẩm của chính bạn và kiểm tra xem máy có thể duy trì chúng ở tốc độ bạn cần hay không.

4.4 Khả năng tương thích của sản phẩm

Kiểm tra phạm vi đã chỉ định cho:

- Kích thước và hình dạng của kẹo dẻo (ví dụ: 3–40 mm, hình gấu, hình vòm, hình vòng, hình dạng tùy chỉnh).

- Lớp phủ như đường hoặc dầu.

- Nhân đơn vị vị so với nhân hỗn hợp vị.

Nếu bạn sản xuất kẹo dẻo có độ dính cao hoặc đặc biệt, hãy yêu cầu nhà cung cấp thực hiện các thử nghiệm và cung cấp cho bạn video và dữ liệu thực tế.

4.5 Thay đổi và vệ sinh

Hầu hết các nhà máy sản xuất kẹo dẻo đều sản xuất nhiều kích cỡ và số lượng chai khác nhau. Mỗi lần chuyển đổi đều gây mất thời gian sản xuất. Bạn muốn:

- Các bộ phận có thiết kế nhẹ, dễ thao tác.

- Dấu hiệu rõ ràng hoặc vạch chia cho các bộ phận hướng dẫn và cảm biến.

- Lưu trữ công thức cho các kết hợp sản phẩm và chai.

- Các bộ phận tiếp xúc có thể tháo rời và vệ sinh nhanh chóng.

Cho Kẹo dẻo vitamin, Vệ sinh không chỉ liên quan đến thẩm mỹ; nó còn giúp ngăn ngừa sự lây lan của đường, dầu và hương vị, đồng thời giảm thiểu rủi ro vi sinh vật.

4.6 Tích hợp đường dây và chi phí tổng thể

Cuối cùng, hãy đảm bảo rằng máy đóng gói kẹo dẻo phù hợp với dây chuyền sản xuất và ngân sách của bạn trong dài hạn:

- Kích thước và điều kiện tiếp cận cho nhân viên vận hành và bảo trì.

- Tín hiệu và giao tiếp với thiết bị ở phía trên và phía dưới.

- Tình trạng sẵn có của phụ tùng thay thế và khoảng thời gian bảo dưỡng thông thường.

Một máy móc chắc chắn, được hỗ trợ tốt có thể có chi phí ban đầu cao hơn nhưng thường dẫn đến chi phí sở hữu tổng thể thấp hơn trong suốt vòng đời của dây chuyền sản xuất.

5. So sánh giữa phương pháp đếm kẹo dẻo và phương pháp cân đo

Hệ thống cân như cân đa đầu kiểm soát tổng trọng lượng, không phải số lượng chính xác từng viên. Điều này có thể chấp nhận được đối với nhiều sản phẩm kẹo, nhưng tiềm ẩn rủi ro đối với các loại kẹo dẻo vitamin và chức năng, nơi nhãn mác cam kết số lượng cố định kẹo dẻo trong mỗi phần ăn.

Một nguyên tắc chung:

- Sử dụng cân đo cho các túi kẹo không yêu cầu liều lượng chính xác và các gói lớn đóng gói theo khối lượng.

- Sử dụng máy đóng gói dạng kẹo dẻo cho chai và lọ, trong đó mỗi viên đóng góp vào liều lượng đã công bố.

Một số nhà máy sử dụng cả hai phương pháp: đếm cho các sản phẩm bổ sung và cân cho các sản phẩm kẹo.

6. Cách chọn máy đếm kẹo dẻo phù hợp

6.1 Khởi nghiệp và các thương hiệu nhỏ

Đối với các startup và thương hiệu nhỏ:

- Số lượng sản phẩm không lớn nhưng sự kết hợp các biến thể sản phẩm có thể thay đổi thường xuyên.

- Ngân sách có hạn.

Một máy đếm kẹo dẻo bán tự động hoặc tự động tốc độ thấp đến trung bình thường là đủ. Ưu tiên tính dễ sử dụng, thời gian chuyển đổi nhanh và khả năng tương thích rộng rãi hơn là tốc độ cực cao.

6.2 Các thương hiệu đang phát triển và đã được khẳng định

Đối với các thương hiệu kẹo dẻo vitamin đã có uy tín:

- Đầu ra phải hỗ trợ nhiều kênh và các chiến dịch quảng cáo.

- Sai sót trong tính toán và thời gian ngừng hoạt động là rất tốn kém.

Bạn nên tìm kiếm thiết bị tự động hoàn toàn có tốc độ cao với:

- Độ chính xác đã được chứng minh trong dòng sản phẩm của bạn.

- Hiệu suất OEE cao và các công cụ chẩn đoán hữu ích.

- Tích hợp tốt với quy trình xử lý chai, đóng nắp và dán nhãn.

Trong nhiều trường hợp, một dây chuyền đếm và đóng chai hoàn chỉnh, thay vì một máy đơn lẻ, mang lại sự cân bằng tối ưu giữa tốc độ, lao động và độ tin cậy.

6.3 Nhà sản xuất theo hợp đồng

Các nhà sản xuất gia công xử lý nhiều loại kẹo dẻo, chai lọ và nhãn mác trong thời gian gấp rút. Họ cần:

- Các máy móc rất linh hoạt có thể xử lý nhiều loại sản phẩm và chai lọ khác nhau.

- Thay đổi công cụ không cần dụng cụ hoặc ít dụng cụ với các thiết lập được ghi chép đầy đủ.

- Các quy trình vệ sinh nhanh chóng hỗ trợ việc thay đổi sản phẩm thường xuyên.

Trong phân khúc này, việc đầu tư vào một dây chuyền sản xuất kẹo dẻo đa năng và được hỗ trợ tốt thường là yếu tố quan trọng để duy trì tính cạnh tranh.

7. Ví dụ về dây chuyền đếm và đóng chai kẹo dẻo

Một cấu hình điển hình cho kẹo dẻo vitamin có thể bao gồm:

- Máy sắp xếp chai nhựa và chai.

- Máy đếm kẹo dẻo tự động đa kênh được thiết kế dành cho các sản phẩm dính.

- Thiết bị chèn chất hút ẩm tùy chọn.

- Máy đóng nắp điều khiển bằng servo và hàn kín bằng cảm ứng.

- Dán nhãn bao quanh và mã Videojet.

Các nhà cung cấp chuyên nghiệp như Cremer, Bellatrx và Ruidapacking cung cấp các dây chuyền đếm và đóng chai kẹo dẻo hoàn chỉnh được cấu hình theo cách này. Sử dụng cấu hình đã được chứng minh giúp giảm rủi ro dự án và dễ dàng mở rộng sản lượng khi nhu cầu tăng cao.

8. Câu hỏi thường gặp về máy đếm kẹo dẻo

Q1: Làm thế nào để Ngăn chặn kẹo dẻo bị vón cục trong keo Quầy?

Chọn máy đếm kẹo dẻo được thiết kế chuyên dụng để xử lý các sản phẩm dính. Tìm kiếm các tính năng như bộ khuấy có gai trong phễu để phá vỡ các cục dính, hệ thống chống vón cục giúp sản phẩm di chuyển liên tục, các tấm lỗ Teflon giảm ma sát bề mặt và cổng xả phủ PTFE giúp kẹo dẻo trượt dễ dàng.

Q2Một máy đếm kẹo dẻo có thể xử lý các hình dạng kẹo dẻo và kích thước chai khác nhau không?

Đúng vậy, hầu hết các máy móc có thể xử lý nhiều kích thước và hình dạng khác nhau miễn là chúng nằm trong giới hạn quy định (3-40mm). Các kích thước chai khác nhau được quản lý thông qua các bộ phận định dạng và công thức lưu trữ. Các viên kẹo dẻo cực nhỏ, quá lớn hoặc dính có thể cần các kênh hoặc cài đặt đặc biệt.

Câu 3: Tôi nên vệ sinh máy đếm kẹo dẻo bao lâu một lần?

Viên kẹo vitamin thường yêu cầu vệ sinh hàng ngày các bộ phận tiếp xúc và cảm biến. Các sản phẩm có hàm lượng đường cao hoặc chứa nhiều dầu mỡ có thể cần vệ sinh nhanh giữa ca làm việc. Tuân thủ các hướng dẫn của nhà cung cấp và quy trình kiểm soát chất lượng của riêng bạn.

9. Kết luận

Sản phẩm kẹo dẻo có sức hấp dẫn đối với người tiêu dùng nhưng đòi hỏi cao về thiết bị sản xuất. Một máy đếm kẹo dẻo được lựa chọn kỹ lưỡng có thể biến quá trình đóng chai kẹo dẻo dính, không đều thành một quy trình ổn định và tốc độ cao. Bằng cách tập trung vào các yếu tố hiệu suất thực tế – thiết kế chống vón cục, độ chính xác đếm, năng suất và tốc độ, thời gian chuyển đổi và vệ sinh, tích hợp dây chuyền và chi phí tổng thể – và đào tạo nhân viên vận hành với các quy tắc khắc phục sự cố đơn giản, bạn có thể duy trì dòng chảy của kẹo dẻo dính, giảm sai sót đếm và dừng máy không mong muốn, đồng thời vận hành dây chuyền đóng chai kẹo dẻo một cách đáng tin cậy khi doanh nghiệp của bạn phát triển.

Tham khảo

Fortune Business Insights – Quy mô thị trường và dự báo tăng trưởng của thị trường thực phẩm bổ sung dạng kẹo dẻo toàn cầu.

https://www.fortunebusinessinsights.com/gummy-supplements-market-109478