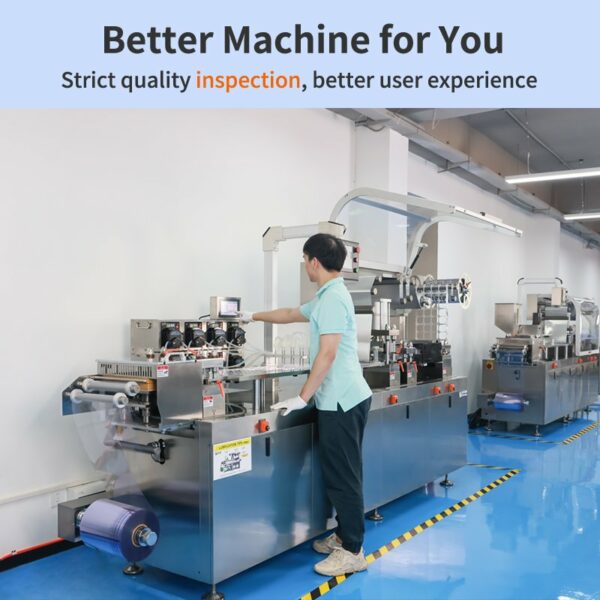

Блистерная упаковочная машина для соусов DPP-270L

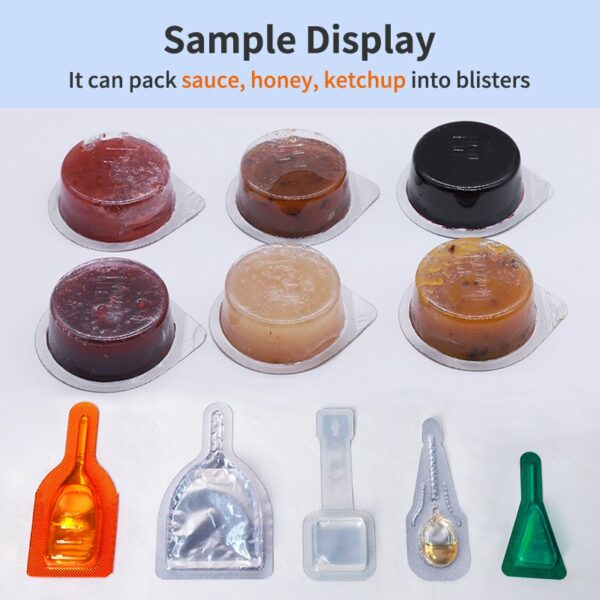

Машина для блистерной упаковки соусов DPP-270L предназначена для упаковки жидких продуктов (таких как сиропы, масла или кремы) в индивидуальные блистерные упаковки.

Нагрев и формование: пленка нагревается до определенной температуры, чтобы стать мягкой и гибкой. Затем она поступает на формовочную станцию, где с помощью набора форм из нее формируются отдельные ячейки (блистеры). Вакуум или давление воздуха используются для формирования в пленке полостей, в которых будет находиться жидкий продукт.

Механизм дозирования: может включать насос, насадку или объемную систему, обеспечивающую точное наполнение каждого блистера необходимым количеством жидкости.

Процесс герметизации: заполненные блистерные упаковки проходят через станцию герметизации, где под воздействием тепла и давления защитная пленка соединяется с основной пленкой. Это создает герметичный карман, защищающий жидкий продукт от загрязнения, утечки или порчи.

Резка: После запечатывания машина разрезает непрерывную полосу блистеров на отдельные упаковки.

Спецификация:

До 9600 тарелок/ч

Применимо для духов, джема, меда…

Подходит для материалов ПВХ, ПС, ПЭТ