Máquina de prensagem de comprimidos de alta velocidade tem as vantagens de alta pressão, fácil operação, manutenção simples, etc. É o produto preferido para produção em massa em empresas farmacêuticas, químicas, eletrônicas, alimentícias e outras, e também um modelo adequado para materiais moldados difíceis de prensar e materiais corrosivos, que atende aos requisitos de produção cGMP.

Capacidade da máquina de prensagem de comprimidos de alta velocidade

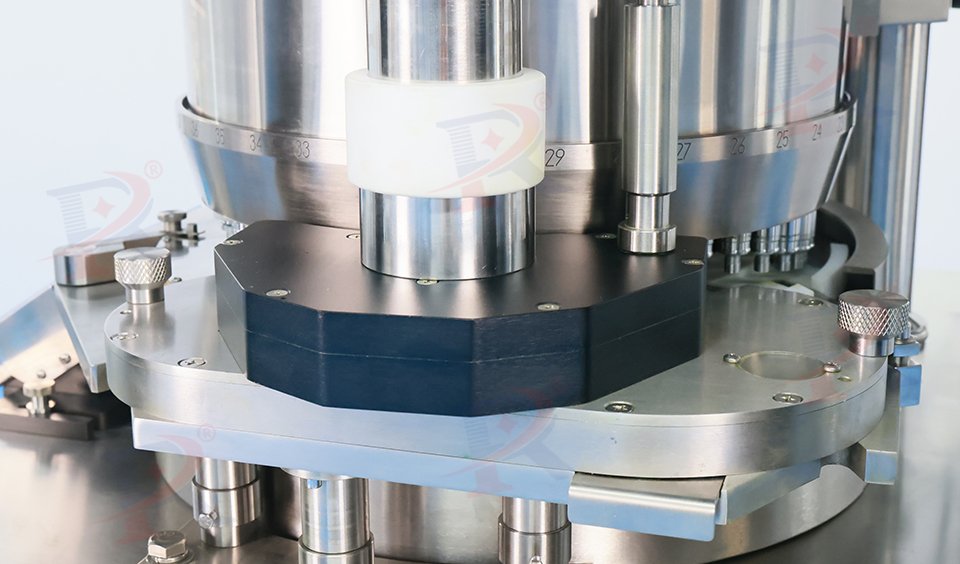

A produção de uma prensa de comprimidos de alta velocidade é geralmente de 100.000 comprimidos/h. A produção é determinada pela velocidade de rotação da mesa giratória e pelo número de punções. A prensa de comprimidos de alta velocidade RQ-HGZP-40 possui uma velocidade de rotação de 110 rpm, 40 punções e uma produção de 264.000 comprimidos/h, que são dados de laboratório. O processo de produção certamente não atinge essa velocidade, afetado pelo material. A produção das prensas de comprimidos no mercado pode ser descontada pela 80% em geral, e isso ainda se aplica a comprimidos redondos comuns, e se forem comprimidos irregulares, a produção ainda é discutível. Se não tiver certeza, entre em contato. Ruidapacking engenheiros.

Função de máquina de prensagem de comprimidos de alta velocidade

É claro que, além da diferença na produção, também existem diferenças na função. As principais características são rejeição única/rejeição em lote, compensação automática do peso do comprimido, controle totalmente automático por CLP e sistema automático de abastecimento de óleo.

Rejeição única

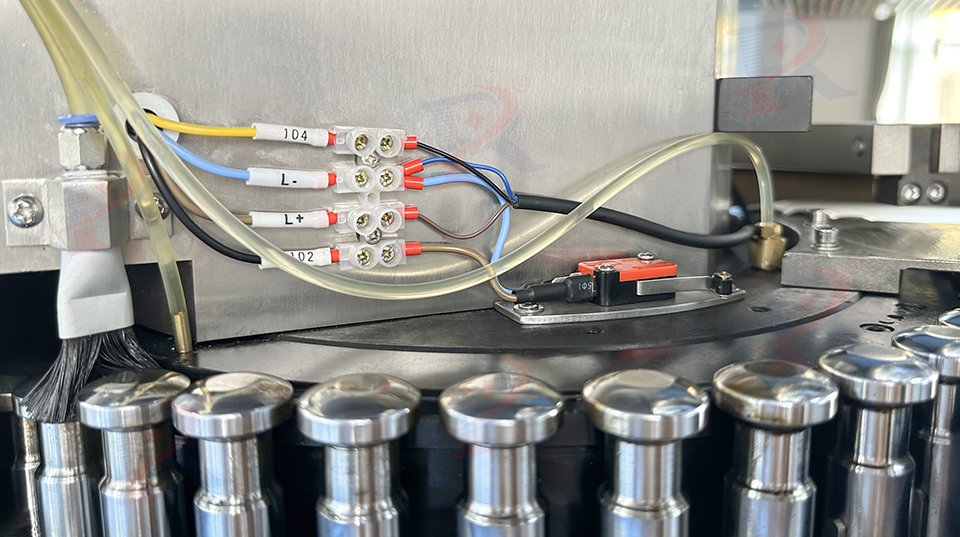

This model has a single piece reject function, which is the biggest difference from other tablet presses. The working principle is based on the mass production of the pressure value of each die, the physical signal through the OMRON sensor into an electronic signal feedback to the PLC, so that you can set the average pressure of a single die tablet, the maximum pressure, the minimum pressure. If the pressure value is within the range of maximum pressure and minimum pressure, the system considers the tablets produced as qualified products. If the pressure value of the die is greater than the set maximum pressure or less than the minimum pressure value, then the tablets pressed by the modified die are unqualified products and are rejected. If the number is reached the machine stops and displays the specific problem on the PLC, and you can react according to this prompt. If the tablets produced by multiple punching dies are unqualified, the machine will also stop when the quantity you set is reached.

Outras prensas rotativas para comprimidos não são precisas o suficiente e só conseguem rejeitar por lote. No entanto, a maioria dos comprimidos rejeitados por rejeição por lote é qualificada, o que causa desperdício de matéria-prima e, invariavelmente, aumenta o custo de produção.

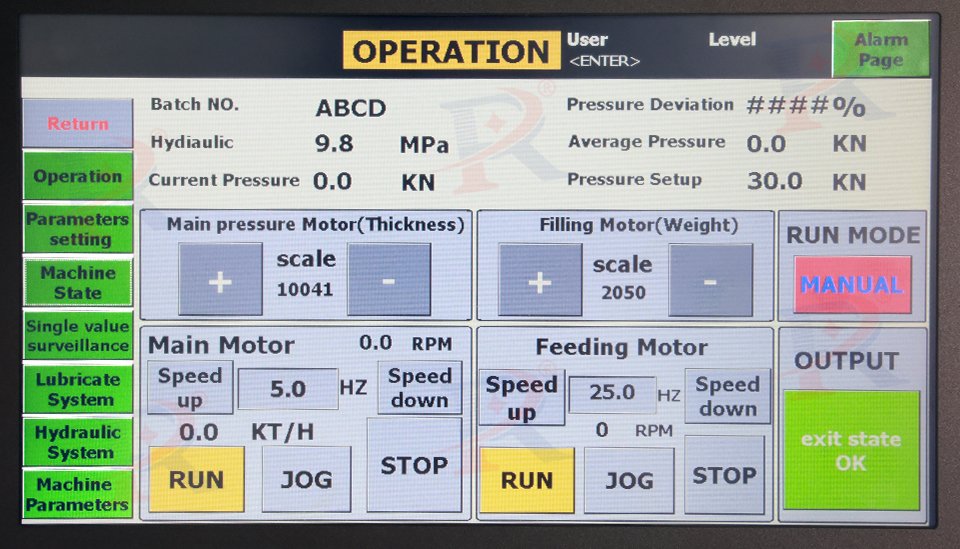

Compensação automática de peso do tablet

Esta função é a personificação da inteligência da prensa de comprimidos. Mesmo que apenas acione um alarme, ainda cabe a você encontrar o problema e corrigi-lo. A compensação automática do comprimido ajusta o valor da pressão de cada punção de acordo com a pressão média dos punções, de modo que a pressão do punção seja mantida dentro de ±3% da pressão média. O princípio de funcionamento é ajustar o enchimento de pó da matriz central de acordo com o valor da pressão de cada punção. Se o valor da pressão for alto, indicando mais pó, o comprimido ficará mais pesado para prensar, e o alimentador forçado reduzirá automaticamente o enchimento do furo da matriz central, e vice-versa.

Esta função pode aprender automaticamente, para que você não precise ficar de olho na produção, de acordo com a qualidade dos tablets para tomar medidas automaticamente, em linha com o padrão inteligente da indústria 4.0.

Controle totalmente automático PLC

Quando você compra o prensa para comprimidosA Ruidapacking foi depurada na fábrica, mas para facilitar o transporte, é necessário desmontar a máquina. Ao receber a prensa de comprimidos, é necessário reinstalá-la e depurá-la. A pressão principal, a pré-pressão e o motor de enchimento de uma prensa de comprimidos de alta velocidade são controlados por servomotores, e todas as operações podem ser realizadas em um CLP. Outras prensas de comprimidos ainda podem ser ajustadas por volante. Se você não tem muita experiência em depurar prensas de comprimidos, é difícil ajustar o equipamento ao estado ideal de produção, pois a parte de controle do motor comum é usada. Todos esses são depurados pela experiência; o nosso não é o mesmo, todos os números são a realidade no CLP, como ajustar rapidamente. É claro que todas as falhas podem ser exibidas no CLP, o que evita que você encontre o problema, e o problema pode ser resolvido diretamente; se não resolver a falha, a prensa de comprimidos não funcionará.

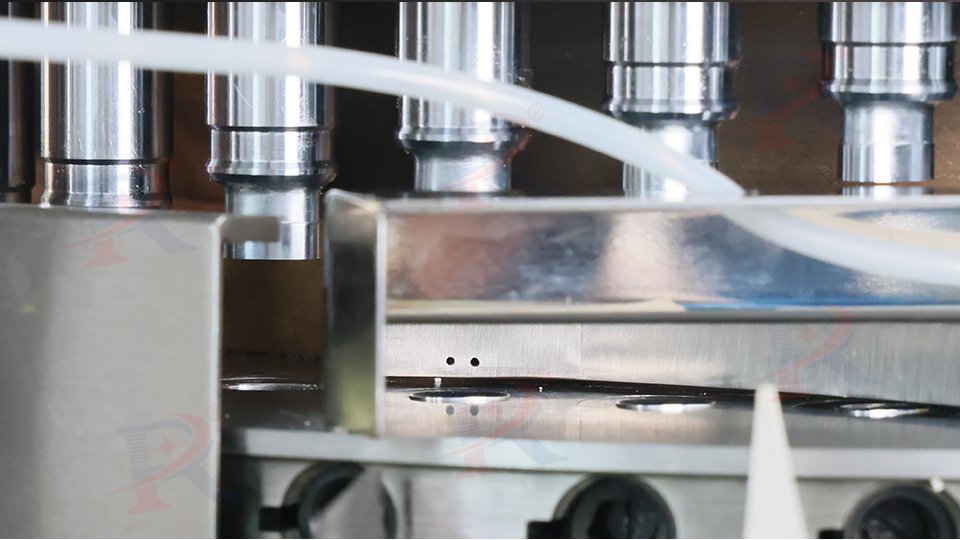

Sistema Automático de Abastecimento de Óleo

Você sabe que, para que máquinas e equipamentos funcionem sem problemas e sem ruídos, é necessário adicionar graxa e lubrificante sólidos. A graxa sólida é adicionada aos rolamentos, que não entram em contato com os comprimidos e o pó, e também para evitar contaminação. O lubrificante é adicionado à matriz e à mesa giratória, pois estas estão em contato direto com o pó, e o lubrificante está em conformidade com os padrões alimentícios. Obviamente, o reabastecimento também é automático, com o sistema ajustando a quantidade de gotas de óleo na mesa giratória a cada volta, sem intervenção humana, para evitar erros por inexperiência.

Aplicação de máquina de prensagem de comprimidos de alta velocidade

Prensas de comprimidos de alta velocidade são cruciais em vários setores, especialmente no farmacêutico, devido à sua capacidade de produzir grandes quantidades de comprimidos de forma eficiente e com alta precisão.

Indústria Farmacêutica

Medicamentos de venda livre (OTC): produz com eficiência grandes volumes de medicamentos comuns, como analgésicos, remédios para resfriado e antiácidos.

Medicamentos prescritos: essenciais para a produção em larga escala de medicamentos prescritos para atender à demanda do mercado.

Nutracêuticos e suplementos: produz vitaminas, minerais e suplementos alimentares em grandes quantidades.

Comprimidos de liberação modificada: capazes de produzir comprimidos com propriedades de liberação controlada, sustentada ou retardada.

Indústria Nutracêutica

Comprimidos de vitaminas: prensas de alta velocidade garantem dosagem consistente e qualidade para suplementos vitamínicos.

Suplementos de ervas: produz grandes lotes de suplementos de ervas com dosagens precisas.

Indústria de Alimentos e Confeitaria

Comprimidos mastigáveis: usados para produzir vitaminas mastigáveis e suplementos alimentares que sejam funcionais e palatáveis.

Comprimidos de energia: produz comprimidos que aumentam a energia, frequentemente encontrados no mercado de esportes e fitness.

As prensas de comprimidos de alta velocidade são essenciais para diversos setores além do farmacêutico, incluindo nutracêuticos e alimentícios. Sua capacidade de produzir grandes quantidades de comprimidos consistentes e de alta qualidade as torna essenciais para atender a altas capacidades e garantir a confiabilidade do produto.