- Lar

- Máquina de embalagem de sacos pré-fabricados

Máquina de embalagem Doypack

As máquinas de envase de sachês pré-fabricados automatizam o enchimento e a selagem em alta velocidade de sachês stand-up, sachês planos e sachês com bico. São essenciais para o envase eficiente de produtos sólidos, líquidos e semissólidos em diversos setores. As principais aplicações incluem produtos farmacêuticos (comprimidos, cápsulas, pós), alimentos e bebidas (bambolês, balas, salgadinhos, café, molhos), cuidados pessoais e cosméticos (loções, xampus, cremes), ração para animais de estimação e produtos químicos. Essas máquinas se destacam no manuseio de sachês pré-formados e impressos, oferecendo dosagem precisa, selagem robusta para a integridade do produto e operação higiênica. Ideais para volumes de produção médios a altos, as ensacadeiras de sachês pré-fabricados otimizam as operações, aprimoram a apresentação do produto, garantem o frescor e a segurança do produto e reduzem significativamente os custos com mão de obra.

Aplicativo:

A máquina de embalagem pré-fabricada com zíper pode embalar cápsulas, ursinhos de goma, doces e café em várias bolsas.

Fluxo de trabalho de cada estação de trabalho

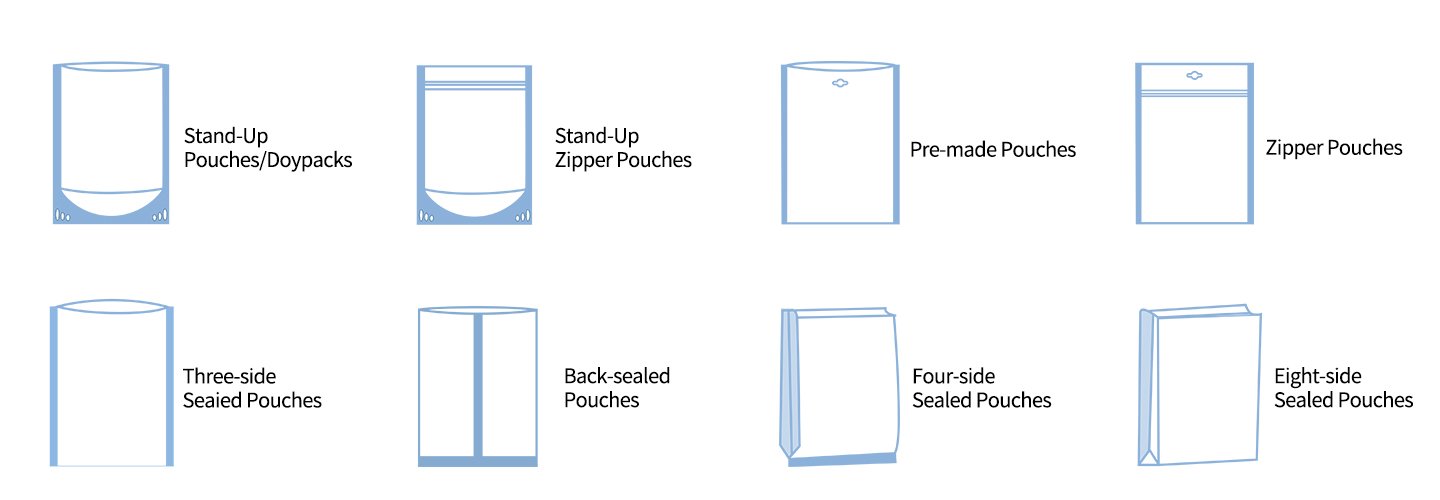

A máquina de embalagem de sacos é uma máquina profissional de embalagem de sacos pré-fabricados para embalar pós, líquidos e sacos de tamanho médio em sacos maiores, como stand-up pouches e sacos com zíper. A máquina oferece funções totalmente automatizadas, incluindo coleta de sacos, codificação, abertura de sacos, abertura de zíper, enchimento de material, dosagem, exaustão de ar (ou descarga de nitrogênio para frescor), organização de sacos, rede e saída do produto acabado.

Características da máquina

A Ruidapacking está comprometida em fabricar máquinas com qualidade superior para atender aos padrões GMP, além de recursos eficientes e utilitários.

Ampla aplicabilidade

Adequado para embalar uma variedade de materiais em sacos pré-fabricados, incluindo doces, nozes, conservas, pós, grânulos, sachês e polpas líquidas.

Design totalmente fechado

Aço inoxidável 316L utilizado nas peças em contato com os materiais, atendendo aos requisitos cGMP. A alta classificação à prova d'água permite fácil limpeza com água e manutenção conveniente.

Ajuste de um botão

O ajuste da largura do saco é concluído automaticamente pelo motor com sincronização de 8 estações de trabalho, permitindo a troca do saco em 2 minutos.

Parâmetros técnicos

Escolha a melhor máquina de acordo com o tamanho das bolsas.

| Modelo | RD-GD-200Pro | RD-GD-260Pro | RD-GD-300Pro | RD-GD-360Pro |

| Saída | 60 bolsas/min | 50 bolsas/min | 50 bolsas/min | 50 bolsas/min |

| Tamanho das bolsas | C: 90-360 mm L: 100-220 mm | C: 150-360 mm L: 150-270 mm | C: 190-460 mm L: 200-310 mm | C: 260-510 mm L: 250-360 mm |

| Poder | 3,5 kW | 4,5 kW | 4,5 kW | 4,5 kW |

Produtos de suporte

Máquina automática de contagem de doces para engarrafamento

Automatic Bottling Candy Counting Machine with its efficient and accurate counting capabilities are widely used in pharma, food, Health care ...

Máquina Automática de Cápsulas Farmacêuticas

Automatic Pharmaceutical Capsule Machine: GMP-compliant, 90,000 capsules/h, ±1% dosing accuracy, supports 000#-5# capsules. Ideal for pharma & nutraceuticals.

Máquina automática de prensagem de comprimidos

Automatic tablet press machine involves compressing powder or granulated into uniform quality tablets through a series of precisely controlled ...

Fornecedor de qualidade da Fortune 500

Os clientes dizem que somos bons

Get praise from SINOPHARMA, GSK, USPharma, Atlantic Grupa, Robinson Pharma…

Gestão 6S

We check every process to ensure machines meet CE, cGMP, ROHS, FDA…

Mould Can Be Customized

Available in different sizes and dimensions of capsules and tablets to suit your needs

Collaborative Projects

You only need to provide the blisters size, and our engineers will take care of the rest.

Depuração no local em todo o mundo

Centro global de atendimento ao cliente in the United States is on standby. You should responsible for engineers’ round-trip air tickets, accommodation and meals + $350/hour

Perguntas frequentes

Design de layout personalizado gratuito: Otimize sua planta baixa, obtenha planejamento especializado de posicionamento de máquinas sem nenhum custo.

Documentação técnica abrangente e guias de solução de problemas: Minimize o tempo de inatividade com acesso instantâneo a manuais e soluções de problemas comuns.

Suporte de vídeo remoto em tempo real: Conecte-se diretamente com engenheiros seniores para resolução rápida de problemas complexos.

Envio global simplificado: Entrega DDP/DDU sem complicações na sua porta, no mundo todo.

Instalação e treinamento local: Configuração, comissionamento e treinamento de operadores no local por nossos técnicos certificados. Desfrute de verdadeira tranquilidade.

Avaliação Anual de Desempenho: Verificações proativas para garantir que seu equipamento opere com eficiência máxima ano após ano.

Em linhas de envase de sachês pré-fabricados, a decisão central de escolher uma balança multicabeça ou uma máquina de contagem de cápsulas de comprimidos como equipamento de apoio depende das características do material a ser manuseado. Essas duas tecnologias oferecem vantagens distintas e são adequadas para aplicações específicas. A escolha da máquina errada pode levar a eficiência comprometida, precisão insuficiente, alto desperdício de material ou até mesmo falha operacional.

Os critérios de seleção, pontos fortes e limitações de cada dispositivo são analisados em detalhes abaixo, com base nas principais características do material:

1. Propriedades do material

Forma física

Grânulos, flocos, bastões, pedaços (sólidos regulares/irregulares): Tanto a balança multicabeçote quanto a máquina de contagem de enchimento são opções possíveis; a seleção final depende de outras propriedades.

Partículas finas: normalmente mais adequadas para máquinas de contagem.

Pós, pastas, líquidos, materiais viscosos: Não são adequadas balanças de pesagem com múltiplas cabeças nem máquinas de contagem automática. Estas requerem equipamentos de enchimento volumétrico (enchedoras de rosca, enchedoras de pistão, enchedoras de líquidos) ou balanças de peso líquido.

Peso/Tamanho Individual

Peso individual grande e relativamente uniforme: (biscoitos grandes, barras de chocolate, frutas inteiras, partes de brinquedos) Balanças combinadas com múltiplas cabeças geralmente oferecem vantagens em eficiência e custo-benefício.

Peso Individual Muito Pequeno ou Altamente Variável: (Pílulas Pequenas, Sementes, Balas de Goma, Hardware Pequeno) As máquinas de contagem eletrônica automática se destacam pela precisão e minimização de desperdícios. Balanças multicabeça têm dificuldade com o controle de precisão para itens muito leves, e itens pequenos são propensos a perdas por "fuga" (aeração) dentro dos baldes de pesagem durante a operação.

2. Balanças multi-cabeça

O material é distribuído de um alimentador vibratório principal para múltiplos baldes de pesagem independentes (tipicamente de 8 a 24) (tremonhas de pesagem). Um sistema computadorizado lê continuamente o peso em cada balde e utiliza um algoritmo de pesagem combinado para identificar rapidamente o grupo de baldes cujo peso combinado se aproxima mais do peso alvo. Os baldes selecionados são descarregados simultaneamente em um funil de coleta localizado abaixo, direcionando o material para a embalagem.

Vantagens

Alta velocidade: O princípio de pesagem combinada permite velocidades de pesagem excepcionalmente altas (normalmente 100-200 bolsas/minuto, com modelos de alta velocidade excedendo 300 bolsas/minuto), tornando-a a escolha preferida para maximizar a produção.

Alta Precisão: Para materiais de fluxo livre com pesos individuais moderados, as balanças multicabeça alcançam uma precisão de pesagem muito alta (±0,1g a ±1g ou melhor, dependendo do material e do peso alvo). O algoritmo de combinação compensa efetivamente as variações individuais de alimentação.

Ampla faixa de peso: capaz de lidar com especificações de embalagem que variam de alguns gramas a vários quilogramas, ajustando o peso alvo e o tamanho do balde, oferecendo forte adaptabilidade.

Ideal para materiais de fluxo livre: processa grânulos, flocos, pedaços e outros materiais de fluxo livre de forma suave e eficiente.

Limpeza e manutenção relativamente fáceis: apresenta uma estrutura relativamente padronizada; as peças em contato com o material (alimentador vibratório, baldes) geralmente são destacáveis para limpeza.

Desvantagens

Problemas com materiais com fluxo ruim: materiais propensos a grudar, aglomerar, serem oleosos ou úmidos podem facilmente entupir o alimentador vibratório, os funis de buffer ou os baldes de pesagem, levando à alimentação irregular, precisão reduzida ou até mesmo parada da máquina.

Desafios com materiais pequenos/muito leves: Itens extremamente pequenos ou leves (sementes minúsculas, pílulas pequenas) são suscetíveis à dispersão pelo fluxo de ar ("voo") dentro dos baldes de pesagem, causando perda de material. As vantagens de precisão também diminuem para pesos-alvo muito pequenos.

Danos potenciais a itens frágeis: a ação de tombamento no alimentador vibratório e na descarga do balde pode causar impacto e atrito, potencialmente danificando produtos muito frágeis (batatas fritas).

Dificuldade com materiais irregulares/enredáveis: itens longos, planos ou fibrosos podem ficar presos ou presos nos trilhos do alimentador vibratório ou nas entradas da caçamba.

Fornece Peso, Não Contagem: Exibe um peso alvo, não uma contagem exata de peças. Inadequado para aplicações que exigem quantidades precisas (itens vendidos por unidade).

3. Elétrico Máquinas de Contagem

As máquinas de contagem de engarrafamento isolam itens individuais usando separação física ou tecnologia de reconhecimento visual e os contam. Os tipos comuns incluem:

Máquina de contagem e enchimento: Os itens ficam em fila em trilhos vibratórios e são contados por meio de sensores fotoelétricos.

Máquina de contagem de inspeção por câmera CCD: câmeras de alta velocidade capturam imagens de itens em queda, e o software de processamento de imagens identifica e conta unidades individuais.

Vantagens

Fornece contagem exata de peças: a única solução para aplicações que exigem contagens precisas (produtos farmacêuticos, ursinhos de goma, doces, componentes eletrônicos).

Manuseio superior de materiais com fluxo ruim: geralmente supera balanças multicabeçotes no processamento de materiais úmidos, oleosos ou pegajosos com risco reduzido de entupimento.

Excelente com pellets pequenos: ideal para contagem de alta precisão e baixo desperdício de pequenos comprimidos, sementes e doces.

Lida com formas irregulares de forma eficaz: contadores de visão avançados podem identificar e contar com precisão itens com geometrias diversas e desafiadoras.

Baixa perda de material: a contagem geralmente evita a inversão do balde de pesagem, minimizando a perda por resíduos de produto ou resíduos de produtos.

Baixo ruído: menos componentes vibratórios em comparação com balanças multicabeçotes geralmente resultam em níveis de ruído mais baixos.

Desvantagens

Velocidade mais lenta: A velocidade absoluta é geralmente menor do que a das balanças multicabeça (especialmente para itens minúsculos). Contadores de visão de alta velocidade podem atingir 100-150 unidades, mas isso se traduz em velocidades de embalagem mais baixas (60-90 bolsas/minuto para pacotes de 100 unidades) em comparação com as balanças de alta velocidade.

A precisão do peso depende da uniformidade da unidade: a precisão da contagem é de 100%, mas a precisão do peso da embalagem depende inteiramente da consistência do peso individual do item. Variações significativas de peso (frutas secas de tamanho irregular, nozes) causam grandes flutuações no peso da embalagem.

Sensibilidade à aglomeração de itens: se dois ou mais itens grudarem e forem contados como um só, ocorre subcontagem. (Exemplo de solução: Nosso contador especializado em doces combate a aglomeração por meio de 4 recursos principais:)

Agitador com funil pontiagudo: evita que as gomas se empilhem verticalmente.

Rolo de distribuição antiaglomerante: garante dispersão uniforme do lote evitando aderência.

Painéis de Teflon Dimple: separam completamente as gomas e permitem um deslizamento suave e rápido.

Porta de descarga de PTFE ampliada: reduz o entupimento, aumentando a velocidade em 58%.

Seleção de equipamentos complexos: diferentes tipos de balcões variam significativamente em adequação de material, exigindo conhecimento especializado e testes para seleção ideal.

Alto custo de contadores de visão: o investimento inicial em sistemas de contagem de visão de alto desempenho pode ser substancial, muitas vezes excedendo os custos de balanças multicabeçais.

Capacidade limitada para itens grandes/pesados: contar pedaços muito grandes (barras de chocolate inteiras, brinquedos grandes) geralmente é estruturalmente impraticável, mais lento e menos econômico do que usar balanças multicabeças.

4. Resumo e Guia de Seleção de Equipamentos

| Recurso | Recomendar balança multi-cabeça | Recomendar Máquina de Contagem Automática |

| Requisito principal | O peso alvo é a prioridade; busque a máxima velocidade e eficiência | A contagem precisa de peças é essencial; ou as propriedades do material tornam a pesagem inadequada |

| Fluidez do material | Bom (seco, fluido) | Ruim/Médio (oleoso, úmido, pegajoso, propenso a formar pontes) |

| Forma Material | Principalmente grânulos, flocos, pedaços | Principalmente partículas finas, micropelotas, formas irregulares, itens planos e alongados |

| Peso individual | Partículas médias a grandes ou pequenas, mas uniformes | Itens muito pequenos ou com grande variação de peso que exigem contagem de peças |

| Precisão da embalagem | Alta precisão de peso (±0,1g – ± 1g) | Precisão de contagem 100% (a precisão do peso depende da uniformidade da peça individual |

| Velocidade | Muito alto (100-300+ bolsas/minuto) | Médio-alto (depende do tamanho do item e da tecnologia de contagem; normalmente mais baixo que os pesadores) |

| Aplicações | Salgadinhos (batatas fritas/nozes/doces), alimentos congelados, ração para animais de estimação, grãos de café, ferragens, grânulos químicos | Produtos farmacêuticos (comprimidos/cápsulas), suplementos, sementes, balas de goma, componentes eletrônicos, itens de alto valor vendidos por contagem |

5. Recomendações de melhores práticas para apoiar a seleção de produtos

Realize testes rigorosos de materiais: envie amostras reais de materiais para a ruidapacking para testes. Veja em primeira mão a capacidade de processamento, a precisão, a velocidade e a perda de material do equipamento com o seu produto específico.

Planeje as necessidades futuras de produção: se você pretende embalar materiais com propriedades diferentes no futuro, priorize equipamentos com compatibilidade ou flexibilidade para lidar com produtos diversos.

Garanta a integração perfeita da linha de produção: garanta que o equipamento de dosagem escolhido se integre perfeitamente aos sistemas de alimentação a montante (elevadores, caixas de armazenamento) e à máquina de embalagem a jusante.

Desempenho da partida: verifique a compatibilidade na velocidade e nas interfaces mecânicas/físicas para evitar gargalos.

Priorize o suporte e o serviço do fornecedor: selecione um fornecedor com sólida experiência técnica e um histórico comprovado de serviço e suporte pós-venda ágil e de alta qualidade.

Ao avaliar cuidadosamente as principais propriedades do seu material e compreender completamente os principais pontos fortes e limitações das balanças multicabeçotes e máquinas automáticas de contagem de garrafas, você pode selecionar com confiança a solução de dosagem mais adequada, eficiente e econômica para sua linha de embalagem de bolsas pré-fabricadas.

Precisa de uma máquina farmacêutica com necessidades especiais?

Nossos engenheiros experientes podem resolver seu problema!

Soluções

© 2024 Ruida Packing Machinery Co., Ltd. Todos os direitos reservados. | política de Privacidade

Links amigáveis: Embalagem Rica | Fabricantes de máquinas de enchimento de cápsulas