- Lar

- Máquina de embalagem de blister

Máquina de embalagem de blister

A máquina de embalagem blister é comumente utilizada nas indústrias farmacêutica, alimentícia e de saúde. Ela embala comprimidos, cápsulas, ampolas e outros produtos pequenos com segurança, protegendo-os da umidade, luz e contaminação, além de oferecer embalagem com lacre de segurança para maior segurança e maior prazo de validade.

Aplicativo:

A máquina de embalagem blister é adequada para diversas capacidades diferentes, incluindo cápsulas, comprimidos e líquidos.

Como funciona

Com funções de conformação, alimentação, selagem a quente, codificação de lote, perfuração e contagem totalmente automáticas, ela sela automaticamente comprimidos, cápsulas, doces e molhos em blisters de alumínio-PVC ou alumínio-alumínio.

A gama completa de máquinas de embalagem de blister

| Modelo | DPP-90R | DPP-100L | DPP-180Pro | DPP-270L | DPP-270Max | DPH-270Max |

| Saída | 2.300 bolhas/h | 2.300 bolhas/h | 4.800 bolhas/h | 9.600 bolhas/h | 11.200 bolhas/h | 27.000 bolhas/h |

| Tamanho máximo da bolha | 80*110*15 mm | 80*110*15 mm | 170*120*15 mm | 255*125*15 mm | 255×125*15 mm | 205×260*12 mm |

| Profundidade Máxima | 26 mm | 26 mm | 26 mm | 26 mm | 26 mm | 26 mm |

Para comprimidos/cápsulas e outros sólidos:

Máquina de embalagem de blister de alumínio e PVC

Alu Pvc blister packing machine can pack tablets, capsules, pill and so on into alu alu or alu pvc blisters, ...

Máquina de embalagem blister de alta velocidade DPP-270Max

A máquina de embalagem blister de alta velocidade DPP-270Max encontra ampla aplicação em diversos setores, incluindo embalagens, farmacêutico e químico.

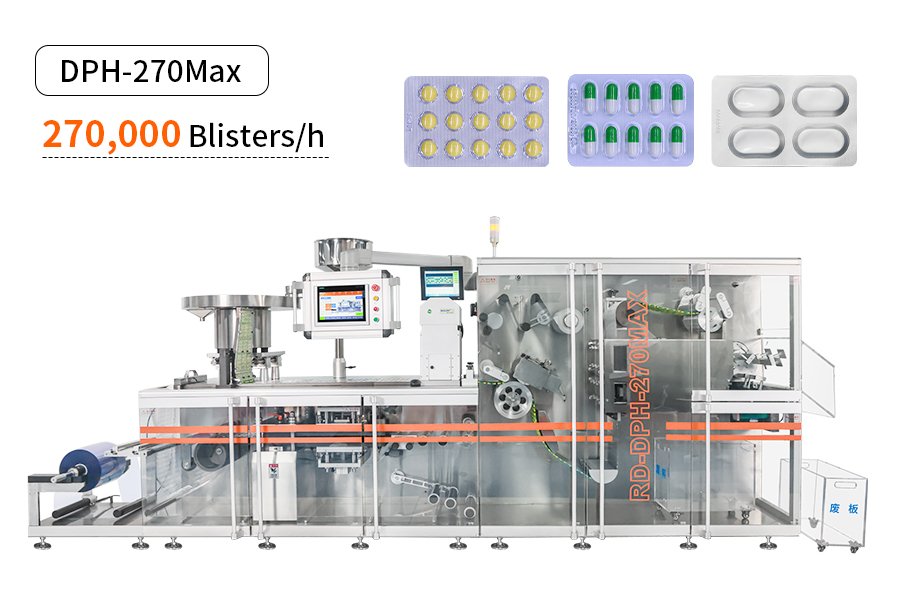

Máquina de embalagem blister de alta velocidade com rolo DPH-270

DPH-270 roller high speed blister packing machine is widely used in the pharmaceutical industries for packaging tablets, capsules, and other ...

Para perfume / geleia / mel e outros líquidos:

Uma mão amiga para embalar seus produtos

Uma mão amiga para embalar seus produtos

Nós cuidamos de você com um serviço completo

Garantia vitalícia

Entrega rápida em 7 dias

Serviço online 24 horas por dia, 7 dias por semana

Perguntas frequentes

- Verifique se os parafusos de cada estação estão apertados e se a pressão do molde está sobrecarregada antes de cada produção.

- Lubrifique regularmente a caixa de comando e a conexão com o molde.

- Quando o equipamento não estiver em uso, desmonte e sele com óleo as matrizes de conformação, selagem a quente e corte.

O que é máquina de embalagem blister?

Uma máquina de embalagem blister é um dispositivo mecânico usado nas indústrias farmacêutica, médica e outras para embalar produtos em blisters.

As embalagens blister consistem em compartimentos ou cavidades individuais que contêm o produto, normalmente comprimidos, cápsulas ou outras formas farmacêuticas sólidas, dentro de um material plástico transparente ou alumínio.

As máquinas de embalagem blister são amplamente utilizadas nas indústrias farmacêutica e de saúde devido à sua capacidade de fornecer uma solução de embalagem segura e inviolável.

Vantagens da embalagem blister

Proteção do produto

Dosagem precisa

Prova de adulteração

Identificação do produto

Melhoria da marca