Alu Alu Blisterverpakkingsmachine

Alu alu blister packaging machine is primarily used in the pharmaceutical industry for packaging sensitive products. Its applications include:

Protection of Medications: Blisterverpakkingsmachine is ideal for packing moisture and light-sensitive drugs. The Alu-Alu (aluminum-aluminum) material provides a high barrier against moisture, oxygen, and light, ensuring that the medications remain stable and effective for longer periods.

Packaging of High-Value Drugs: Due to its superior protection, the machine is often used for packaging high-value and life-saving drugs, such as oncology medications, biotech products, and other critical formulations.

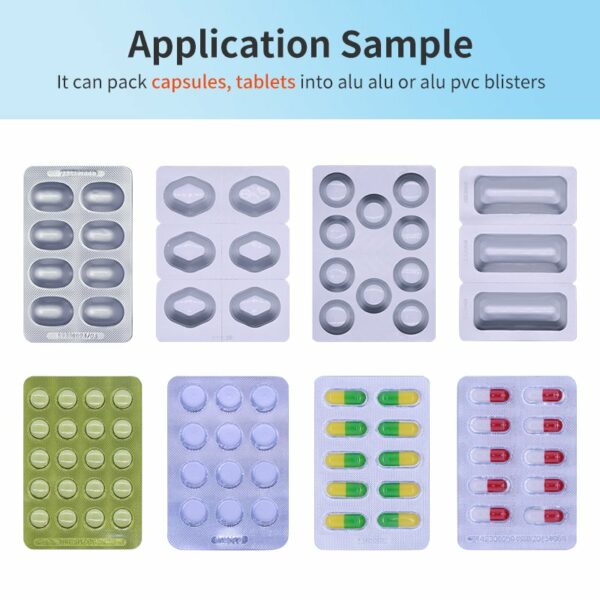

Blister Packs for Tablets and Capsules: It is widely used for packaging tablets and capsules in a sealed, protective environment, maintaining product integrity from the manufacturer to the consumer.

Specificatie:

Tot 4.200 blaren/u

Applicable for tablets, capsules medicine