Stof is geen klein probleem: het vreet stilletjes aan uw winst

Heb je ooit voor een volledig automatische capsule-vulmachine En een poederwolk de lucht in zien drijven? In eerste instantie lijkt het misschien onbelangrijk – gewoon wat rondzwevend stof. Maar al snel beseft u dat het verre van ongevaarlijk is. Dat poeder betekent verlies van grondstoffen, vaker schoonmaken, besmettingsrisico's en nog snellere slijtage van de kerncomponenten van uw machine.

Voor fabrikanten met grote productiebehoeften in de farmaceutische en nutraceutische sector zijn dit geen kleine ongemakken: ze ondermijnen ongemerkt uw winst, verstoren de productie en maken het moeilijker om te voldoen aan cGMP-voorschriften.

De waarheid is dat stofproblemen niet zomaar kunnen worden opgelost door harder te stofzuigen of langere schoonmaakbeurten. Dat gaat alleen ten koste van de uptime en de arbeid, zonder het echte probleem aan te pakken: waar de poederlekkage begint. Een gekwalificeerde machinefabrikant moet de technologie voor het vullen van capsules voor complexe materialen zoals probiotica, kruidenpoeders en micropellets beheersen, en zo nauwkeurige dosering en effectieve poederopvang garanderen voor een stofvrije, cGMP-conforme werkruimte.

Dit is waar de NJP1500D van Ruidapacking van pas komt. Het is een volautomatische capsule-vulmachine Met de grootste productiecapaciteit van 90.000 stuks/u, ontworpen met poedercontrole als kern. Het pakt stof op drie fronten aan: bij de bron, via luchtstroombeheer en via terugwinningssystemen. Het resultaat is een schonere, meer compliante en efficiëntere productielijn.

Want uiteindelijk is elk deeltje poeder waardevol, en elk deeltje levert winst op.

Als stof het probleem is dat stilletjes de winst aantast, dan is ontwerp de oplossing. In plaats van symptomen te bestrijden, pakt de NJP1500D van Ruidapacking de oorzaak van poederlekkage aan – door middel van een systematische, cGMP-conforme aanpak van stofbeheersing.

Een systematische aanpak van stofbeheersing

Stof oplossen gaat niet om meer afzuiging of vaker schoonmaken. Echte beheersing vereist een systematisch, cGMP-conform ontwerp dat poeder in elke fase van het vullen van capsules aanpakt.

De NJP1500D introduceert een vierfasen-framework dat stof stevig onder controle houdt:

| Controle bij de bron | 3D-openingaanpassing (0,06 mm) |

| Sluit het goed af | Volledige behuizing + dubbel afdichtingssysteem |

| Beheer de luchtstroom | Lager Positief Blazen × Zuigpoort |

| Herstellen en hergebruiken | Eenvoudig reinigen + poederrecycling |

Elk van deze elementen speelt een unieke rol en samen creëren ze een gesloten kringloop van stofbeheersing. In de volgende paragrafen bekijken we hoe elke fase werkt en waarom dit belangrijk is voor fabrikanten die waarde hechten aan opbrengst, naleving en kosten.

1. Controle bij de bron – 3D-openingsaanpassing

Elke stofwolk heeft een beginpunt. Bij het vullen van capsules is dat punt de kleine ruimte tussen de doseerschijf en de koperen plaat. Als de ruimte te groot is, lekt het poeder ongecontroleerd weg. Is de ruimte te klein, dan heeft de machine moeite met vullen, wat leidt tot stilstand en ongelijkmatige vullingen.

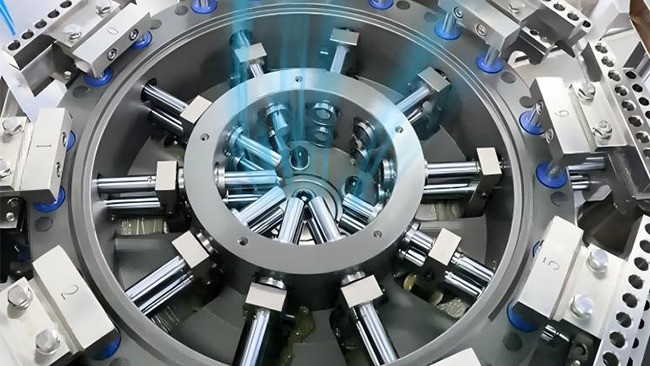

De meeste machines dwingen fabrikanten, met name farmaceutische fabrikanten, tot dit compromis: meer stof of meer storingen. Maar de NJP1500D doorbreekt de cirkel met zijn gepatenteerde 3D-systeem voor het instellen van de spleet.

Dit systeem stemt de opening in drie dimensies nauwkeurig af met micrometerprecisie, tot wel 0,06 mm – dunner dan een mensenhaar. Het resultaat is een perfect uitgebalanceerde ruimte: breed genoeg om de bewerkingen soepel te laten verlopen, maar smal genoeg om verspilling te minimaliseren.

De voordelen gaan verder dan alleen 'minder rommel'. Met een stabiele dosering krijgt u:

➸ Consistent capsulegewicht → hogere batchuniformiteit.

➸ Minder materiaalverspilling → Elke gram poeder gaat verder.

➸ Minder schoonmaakonderbrekingen → meer uptime en efficiëntie.

Zoals een klant het verwoordde: "Vroeger moesten we vaak stoppen om opgehoopt poeder te verwijderen. Nu draait de NJP1500D gewoon – en schoon."

Door stofdeeltjes bij de bron aan te pakken, zorgt de NJP1500D ervoor dat stofproblemen nooit meer de kans krijgen om te ontstaan.

2. Sluit het goed af

Volledige behuizing + dubbel afdichtingssysteem + positieve luchtstroom

Bij capsule-encapsulatie kan, zelfs bij nauwkeurige dosering, nog steeds stof ontsnappen als de constructie van de machine niet luchtdicht is. Daarom neemt de NJP1500D geen enkel risico: de volledige behuizing is gebouwd als een volledig gesloten roestvrijstalen systeem, compleet met een transparante isolatiekap. Dit ontwerp houdt het poeder binnen, beschermt de operator en zorgt voor een schone productieomgeving.

Maar daar stopten we niet. Op het meest kwetsbare punt van de machine – de roterende assen – voegden we een nationaal gepatenteerd dubbel afdichtingssysteem toe:

Eerste verdedigingslinie: NBR-nitrilrubber

Voorkomt lekkage van smeermiddel in het lager. Geen olielekkage, geen risico op verontreiniging.

Tweede verdedigingslinie: geïmporteerde SIL-siliconen

Voorkomt dat poeder de lagerkamer binnendringt, waardoor de machine wordt beschermd tegen voortijdige slijtage en kostbare stilstand.

De kern van dit systeem is ons "geheime wapen": positieve lucht die rechtstreeks op de lagers blaast. Door de luchtdruk in de lagerbehuizing te controleren, duwt de machine poederdeeltjes weg voordat ze zich kunnen nestelen of naar binnen sluipen. Geen stof in de lagers betekent geen verborgen slijtage en geen onverwachte storingen. Met andere woorden, zelfs als er poeder in de buurt komt, wordt het direct weggeblazen, waardoor de lagers schoon, veilig en duurzaam blijven.

Samen vormen deze drie lagen – volledige behuizing, dubbele afdichting en positieve luchtstroom naar het lager – een complete verdediging. Er ontsnapt geen poeder, er lekt geen olie en er kan geen verontreiniging binnendringen.

Denk eens aan het verschil:

Bij een standaard capsule-vulmachine sluipt poeder in het lager en slijt het oppervlak, waardoor kostbare reparaties aan de machine nodig zijn.

Op de NJP1500D, een drievoudig beschermingssysteem: volledige behuizing, dubbele afdichtingen en gepatenteerde positieve luchtstroom voorkomt dit. Lagers blijven schoon, beschermd en efficiënt, waardoor de levensduur wordt verlengd en duizenden euro's aan onderhoudskosten worden bespaard.

Voor fabrikanten betekent dit minder zorgen over kruisbesmetting tijdens audits en minder geld uitgegeven aan vervangingsonderdelen. Het is een eenvoudig principe: als je het goed afsluit, en zorg dat de lucht goed blijft stromen, verloopt de rest soepeler.

3. Dubbele druk zuigpoort: positief + Negatief Haven

Tussen het capsulezaaistation en de afvoeropening beschikt de NJP1500D over een speciaal ontworpen zuigpoort met dubbele druk. Dit is de kritieke zone waar poeder de neiging heeft te morsen, zich op te hopen of te bezinken – en daar maakt ons luchtstroomontwerp het verschil.

Dit is hoe het werkt:

Blazen met positieve druk → Niet alleen het lager heeft de functie van positieve luchtblazen, maar ook het aanzuigstation. Een gecontroleerde luchtstroom wordt bij de aanzuigopening vrijgegeven en tilt los of plakkerig poeder op dat anders aan oppervlakken zou blijven plakken of op ongewenste plekken zou vallen.

Onderdrukzuiging → Zodra poeder in de lucht komt, wordt het door de vacuümleiding opgevangen en direct naar het opvangsysteem geleid.

Stel je voor dat een bezem het stof in de lucht veegt, terwijl er boven je al een stofzuiger klaarstaat. Het stof krijgt dan geen kans om zich te verspreiden of te verontreinigen.

Door blazen en zuigen in één gecoördineerde stap te combineren, zorgt de zuigpoort voor:

Schoner zaaien van capsules: geen verdwaald poeder dat de uitlijning van de capsules verstoort.

Schonere afvoer – de capsules komen eruit zonder overtollig poeder mee te nemen.

Schonere omgeving – geen stof dat blijft hangen in de machine of de werkplaats.

Deze strategische aanzuigpoort is meer dan een klein detail: het is de eerste verdedigingslinie tegen ontsnappend kruit en verandert een van de stoffigste plekken bij het vullen van capsules in een van de schoonste.

4. Eenvoudig schoonmaken

Zelfs met de beste controle zal er altijd wat poeder ontsnappen – dat is inherent aan capsuleproductie. Maar met de NJP1500D gaat er niets verloren.

En in tegenstelling tot conventionele machines met hoge frames en onbereikbare hoeken, heeft de NJP1500D een laag platform zonder dode hoeken. Operators kunnen gemakkelijk elk oppervlak, elke rand en elke hoek stofzuigen of afnemen – zonder demontage, zonder tijdverspilling. Wanneer de productie stopt, is schoonmaken verfrissend eenvoudig:

Gebruik een stofzuigermondstuk om snel stof te verwijderen.

Veeg af met alcoholdoekjes voor een vlekkeloze afwerking.

Zoals een operator het verwoordde: "Vroeger gooiden we elke week kilo's poeder weg. Nu, met het terugwinningssysteem, besparen we grondstoffen en uren aan handmatige reiniging."

5. Poederrecycling – geen afval, meer waarde

Elke gram poeder is kostbaar, vooral in de farmaceutische en nutraceutische productie. Bij veel capsulevullers wordt gemorst poeder simpelweg weggezogen en weggegooid. Dat is verspilling van materiaal, geld en potentieel.

De NJP1500D hanteert een slimmere aanpak met zijn speciale poederrecyclingsysteem:

Onder de machine bevindt zich een opvangbak van roestvrij staal 316L, die overtollig poeder opvangt.

Vanuit de bak loopt een directe aanzuigleiding rechtstreeks terug naar de doseerschijf. Dit ontwerp zorgt ervoor dat het poeder niet alleen wordt opgeslagen, maar ook actief wordt teruggezogen naar de vulsectie.

Dankzij de stabiele zuigkracht behoudt het gerecyclede poeder zijn integriteit en kan het 100% worden hergebruikt: geen verlies, geen compromissen.

Zoals een operator zei: "Vroeger gooiden we elke week kilo's poeder weg. Nu gaat alles direct terug in het proces – we besparen zowel op grondstof als op schoonmaakwerk."

Het resultaat is een overwinning op alle fronten:

Geen afval – elk winbaar deeltje gaat terug in de productie.

Lagere grondstofkosten – maximaliseer het gebruik van formules met een hoge waarde.

Hogere opbrengst en efficiëntie – minder uitvaltijd, meer output.

Met de NJP1500D stopt de poederbeheersing niet bij het reinigen; het voltooit de cyclus en zet potentieel afval om in meetbare waarde.

Conclusie

Dankzij de nauwkeurige afstelling, strakke afdichting, gecontroleerde luchtstroom en efficiënte terugwinning vult de NJP1500D niet alleen capsules, maar verwerkt het ook poeder als geen ander apparaat in zijn klasse.

Als uw formule bijzonder licht, plakkerig of lastig te hanteren is, kan ons team een oplossing voor stofbeheersing op maat voor u samenstellen.

✨ Ruidapacking. Precisie in elke verpakking. Vraag vandaag nog uw offerte aan.

Veelgestelde vragen over de NJP1500D capsule-vulmachine

V1: Welke onderdelen van de capsule vulmachine zijn het meest gevoelig voor poedervorming? Is er in het ontwerp rekening gehouden met dode hoeken?

A: Poeder heeft de neiging zich tijdens het gebruik op te hopen rond de doseerschijf, de onderste matrijsgaten en de afvoerpoorten, met name in de verbinding tussen de werkstations. Om dode hoeken te voorkomen, is de machine ontworpen met een breed platform, gladde, spiegelglad gepolijste contactvlakken en afgeronde overgangen. Elk onderdeel is gemakkelijk te bereiken. U kunt de machine eenvoudig schoonvegen of een stofzuiger gebruiken. Belangrijke componenten zijn eenvoudig te demonteren voor reiniging, zodat er geen poeder ophoopt in verborgen ruimtes en de apparatuur volledig voldoet aan de cGMP-hygiënevoorschriften.

Vraag 2: Hoe lang duurt het meestal om de machine schoon te maken nadat de productie is gestopt?

A: Een routinematige reiniging duurt doorgaans ongeveer 15 minuten, afhankelijk van het product en het proces. De machine is ontworpen met snel te verwijderen onderdelen en gladde contactoppervlakken, waardoor operators poederresten gemakkelijk kunnen verwijderen zonder speciaal gereedschap. Voor grondige reiniging of productwisselingen kan een meer gedetailleerde wasbeurt langer duren, ongeveer een halve dag, binnen 4 uur. Als de operator de machine goed kent, kan de tijd worden verkort tot 3 uur, wat bespaart op onderhoud en tijd.

V3: Zal er stof in de kerncomponenten komen waardoor er frequent onderhoud nodig is?

A: Nee. De machine is uitgerust met meerdere afdichtingen en stofdichte constructies die voorkomen dat er poeder in gevoelige zones zoals de lagers, de indexeerkast en de turret terechtkomt. Deze bescherming minimaliseert slijtage en garandeert stabiele prestaties op lange termijn, waardoor er minder frequent onderhoud nodig is.

Vraag 4: Wat is de rol van de vacuümzuigpoort bij positieve luchtstroom en negatieve zuiging?

A: Positieve druk blaast het poeder omhoog, terwijl een gesynchroniseerde vacuümleiding het met negatieve druk opvangt. Dit creëert een onzichtbaar luchtschild die de machine schoon en stofvrij houdt.

V5: Voldoet de machine aan CGMP-vereisten voor reinheid en preventie van kruisbesmetting?

A: Ja. De machine is volledig ontworpen volgens de GMP-normen. Het aandrijfgedeelte bevindt zich aan de onderkant. Alle onderdelen die in contact komen met het product zijn gemaakt van roestvrij staal van farmaceutische kwaliteit met spiegelglad gepolijste oppervlakken (Ra ≤ 0,8 µm) om residuvorming te voorkomen. De machine heeft vier deuren. Zodra u deze tijdens het proces opent, stopt de machine onmiddellijk, wat de veiligheid van mensen beschermt. Het poeder dat we hergebruiken, komt niet in contact met het stof van buitenaf, waardoor het risico op kruisbesmetting tot een minimum wordt beperkt.

Q6: Voor welke formules is deze machine geschikt?

A: De NJP1500D is veelzijdig, maar is vooral waardevol voor lichte, kleverige of hoogwaardige poeders, waarbij stofbeheersing een groot verschil maakt in opbrengst en kostenbesparing. Neem contact met ons op als u zeer specifieke vragen of problemen heeft. Ons team biedt professionele oplossingen voor uw producten.