- 家

- カプセル充填機

カプセル充填機

Classification of Capsule filling Machine

| 機械モデル | NJP-400C | NJP-800C | NJP-1500D | NJP-2600C | NJP-3800D | NJP-5500C |

| 最大出力 | 24000個/時 | 48000個/時 | 90000個/時 | 150000個/時 | 228000個/時 | 330000個/時 |

| カプセルサイズの互換性 | 000,00,0,1,2,3,4,5# | |||||

| 力 | 3KW | 5kW | 5.5kW | 8kW | 10.5kW | 11kW |

| 重さ | 600キログラム | 900キログラム | 1200キログラム | 1500キログラム | 2200キログラム | 3000キログラム |

| 寸法 | 1000×710×1900mm | 1100×910×2100mm | 1490×1260×2150mm | 1650×1490×2150mm | 1980×1850×2200mm | 2400x2050x2300mm |

| モデル | CGN-208 | CGNT-209 |

| 出力 | 15000-30000pcs/h | 40000pcs/h |

| Applicable Capsule | 000#、00#、0#、1#、2#、3#、4#、5# | |

| 電源 | 2.12kW | 2.2kw |

| 力 | 380/220V 50Hz(カスタマイズ可能) | |

| Net weight | 400kg | 405kg |

| Packing size | 1640×720×1700mm | 1640×720×1700mm |

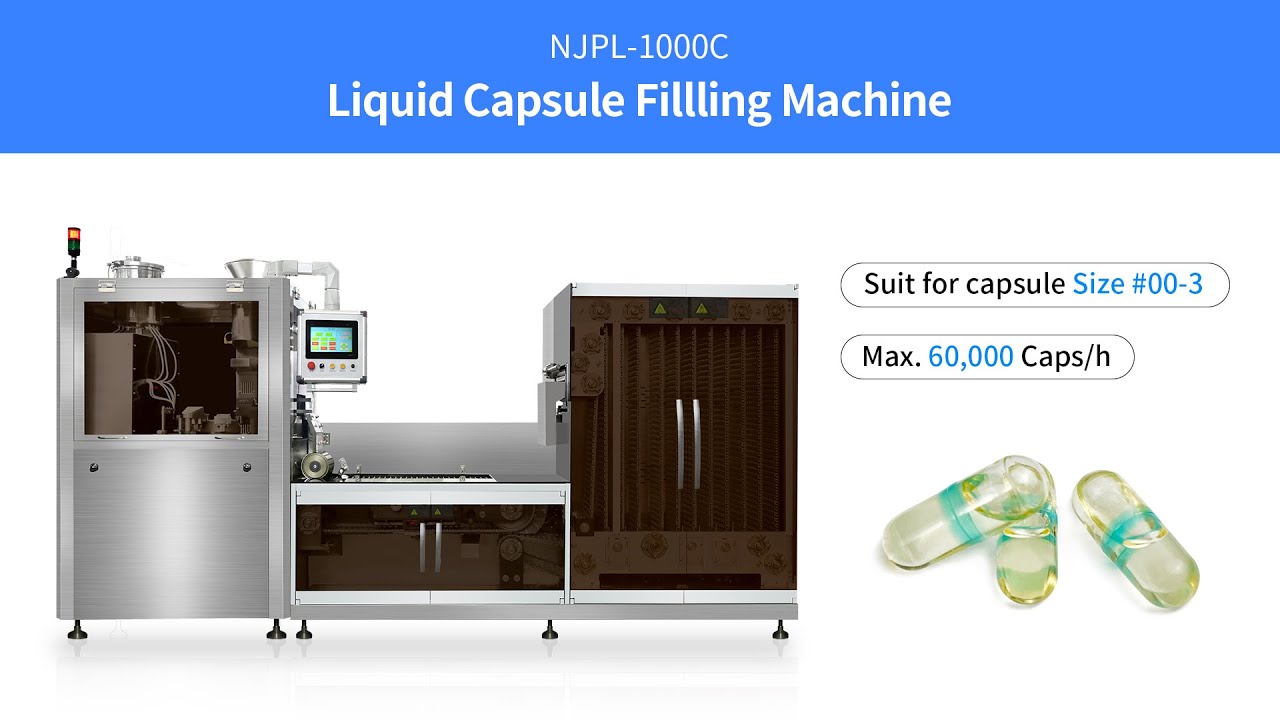

| モデル | CGNL-300 | NJPL-100C | NJPL-300C | NJPL-600C |

| 出力 | 15000-28000pcs/h | 100個/分 | 300個/分 | 600個/分 |

| カプセルサイズの互換性 | 00#、0#、1#、2#、3# | |||

| 総電力 | 2.12kW | 3.5KW | 5kW | 6KW |

| 力 | 380/220V 50Hz(カスタマイズ可能) | |||

| 重さ | 400KG | 500KG | 750KG | 900KG |

| 寸法(L*W*H) | 1300*800*1750mm | 700*800*1700mm | 860*960*1800mm | 960*1000*1900mm |

どのマシンが最適か分からないですか?当社のチームがお客様のニーズと予算に基づいたご提案をさせていただきます。

自動カプセル充填機

Benefits

- Less labor costs

- Higher output than semi-automatic with one operator

- Integrated automation to complete capsule

- The whole process without pollution

Application:

- size:#000 to #5

- Ingredients: pellet, powder, granule

半自動カプセル充填機

- Easy to Use

- Lower Machine Costs

- Higher Output with More Operators

- size:#000 to #5

- Ingredients: pellet, powder, granule

半自動カプセル充填機

Semi automatic capsule filler machine can fill powder, granule, pellet and liquid into hard capsule, suitable for capsule size ...

Liquid Capsule filling Machine

Benefits

- Latest technologies without leakage

- The whole process without pollution

- Various liquid application

Application:

- size: #000 to #3

- Ingredients: liquid, oil, liquid/mini capsule, liquid/mini tablet, liquid/pellet

製薬業界にとって賢明な投資

Wide Application

高精度

Cost Effective

No Messy Workshop

包括的なサービスでお客様をサポートします

生涯保証

7日以内に迅速に配送

24時間365日オンラインサービス

よくある質問

- カムを良好な状態に保つために定期的に潤滑してください。

- 生産が終了したら、詰まりや錆を防ぐために充填ステーションを分解して清掃し、余分な材料を取り除きます。

- 定期的に真空ポンプに潤滑油を補充し、ほこりを取り除いてください。

- 定期的に水タンクに樽本体の半分以上まで十分な水を入れてください。

Capsule Filling Machine Working Principle

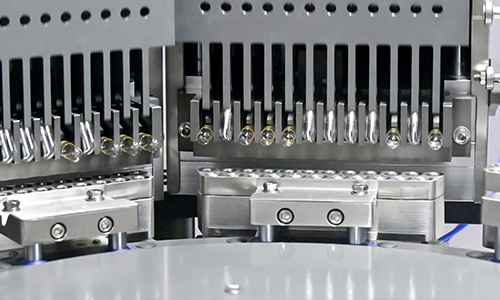

Step #1: Capsule Separation

The machine separates the empty capsules into individual halves, typically using mechanical or vacuum-based mechanisms.

Step #2: Filling Material

The desired fill material, such as powders or granules, is loaded into a hopper.

Step #3: Capsule Closing

The machine brings the capsule halves together, aligns them, and securely closes them using either mechanical pressure, vacuum suction, or a combination of both.

Step #4: Ejection

Once the capsules are closed, they are released from the machine, either into a container or for further packaging.

カプセル充填機とは何ですか?

A capsule filling machine is a device used in the 医薬品, nutraceutical、 そして herbal industries to automate the process of filling empty capsules with various substances such as powders, granules, pellets, or liquids.

It consists of different components, including a capsule hopper, a mechanism for separating and orienting the capsules, a filling system, a closing mechanism, and an ejection system.

The machine facilitates efficient and precise filling of capsules, ensuring accurate dosage and uniformity. It helps increase production speed, reduce labor costs, and maintain quality control in capsule manufacturing processes.

Main Types of Capsules

Hard-Shelled Capsules

- Hard-shelled capsules, also known as two-piece capsules, are composed of separate cap and body sections that fit together to enclose the fill material. The cap and body are typically made of gelatin or vegetarian materials.

- Hard capsules offer excellent product protection, stability, and tamper-evident features. They are commonly used for dry powders, granules, or small solid particles.

Soft-Shelled Capsules

- Soft-shelled capsules are composed of a single, flexible gelatin or vegetarian shell. They are often referred to as softgels or softgel capsules. Softgels are typically filled with liquid or semi-solid materials, such as oils, suspensions, or pastes.

- The soft shell provides advantages such as enhanced bioavailability for lipid-based formulations, improved stability for light-sensitive compounds, and ease of swallowing.