30 Mei 2025, Guangzhou, Ruida Packing telah menetapkan tolok ukur baru dalam solusi farmasi menyeluruh dengan keberhasilan penerapan dua lini produksi yang terintegrasi sepenuhnya untuk klien Aslam yang berbasis di UEA. Proyek yang menampilkan lini pembotolan penghitungan kecepatan tinggi dan sistem pengisian bubuk presisi, menunjukkan komitmen Ruida terhadap dukungan teknis yang profesional dan layanan siap pakai yang unggul.

Tantangan Klien: Kendala Anggaran Dihadapi dengan Integritas Teknik

Menghadapi keterbatasan modal untuk peralatan, Aslam mengevaluasi 5 pemasok Tiongkok. Ruida memenangkan kontrak bukan karena harga terendah, tetapi karena sikap teguh Manajer Bisnis Owen:

“Owen langsung merespons, bahkan pada tengah malam waktunya. Ketika solusi tidak memungkinkan, ia mengatakannya di awal. Vendor lain menjanjikan pembayaran di muka, tetapi kemudian membatalkannya.” Aslam.

Rincian Teknis: Dua Jalur Produksi

1. Lini Penghitungan dan Pembotolan (Sesuai cGMP)

Pembuka botol, Elektronik penghitung kapsul tablet(100 botol/menit), Pemeriksa berat, Penyisip pengering, Penutup, Penyegel foil induksi, Pemberi label.

2. Lini Pengisian Serbuk (Akurasi 0,1g)

Pengumpan mangkuk getar, mesin pengisian bubuk otomatis (kisaran 25-500g), penutup roda bintang, penyegel foil anti-rusak, pelabel peka posisi, mesin selongsong.

Perbedaan Layanan Ruida: Jaminan 4 Pilar

Transparansi Produksi Real-Time

Owen membagikan pembaruan foto/video mingguan selama proses produksi—menghilangkan kecemasan “kotak hitam” bagi pembeli internasional.

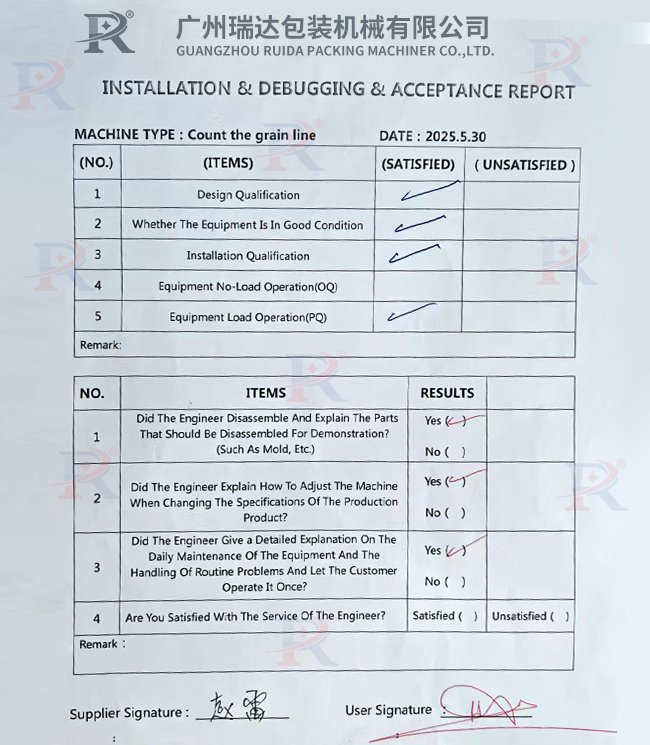

Pelatihan di Tempat 3-Fase (Dilakukan oleh Insinyur Zhao)

| Fase | Proses | Hasil Klien |

| Demonstrasi | Pengaturan mesin uji coba dan penyetelan parameter | Memahami logika operasional |

| Operasi Terpandu | Penyesuaian langsung untuk bahan yang berbeda | Protokol pergantian master |

| Validasi Independen | Insinyur klien beroperasi di bawah pengawasan | Penilaian kompetensi lulus/gagal |

“Insinyur Zhao melatih kami hingga kami dapat menjalankan batch selama 8 jam tanpa kesalahan. Ini bukan pelatihan, melainkan transfer pengetahuan.” Umpan balik tim Aslam.

Integrasi Pemeliharaan Preventif

Diagnostik jarak jauh menyelesaikan masalah 70% tanpa kunjungan di tempat.

Dokumentasi Lengkap

Manual multibahasa (Arab/Inggris).

Set lengkap video Pemecahan Masalah.

Mengapa Memilih Ruidapacking

Tidak Ada Kemampuan Tersembunyi: Batasan mesin didokumentasikan sebelum penandatanganan kontrak.

Kepemilikan FOB-ke-Komisi: Akuntabilitas titik tunggal dari pabrik hingga peluncuran produksi.

Kepatuhan cGMP Terpadu: Semua mesin dilengkapi templat IQ/OQ/PQ yang dapat divalidasi.

Dampak Industri

Proyek ini menyoroti tren yang berkembang: 62% perusahaan farmasi pasar berkembang kini memprioritaskan kejujuran teknis daripada harga terendah (Survei PharmaTech 2025). Solusi Ruida menyingkirkan solusi Aslam:

Ketakutan logistik (ketidaksesuaian peralatan)

Kesenjangan pelatihan (operator lini pertama kali)

Risiko waktu henti (pemeliharaan tak terencana)

Putusan Klien: Mendefinisikan Ulang Nilai

“Ruida membuktikan bahwa 'hemat biaya' berarti keandalan seumur hidup—bukan hanya penghematan di awal. Teknisi mereka bekerja ekstra selama 3 hari hingga lini produksi bubuk kami mencapai 99,2% OEE. Itulah kemitraan sejati.” kata Aslam.