For many engineers and production technicians who work with tablet press machines, one persistent question often arises: Why is there always powder residue on the rotary table during tablet production?

Whether it’s a high-end intelligent tablet press, a mid-range rotary tablet press, or a small laboratory tablet press, this issue seems unavoidable. Understanding the reason behind this phenomenon requires a closer look into the tablet compression process, the machine’s structure, and the balance between mechanical precision and material properties.

1. Where Does the Powder Come From?

To solve a problem, we must first understand its origin. The powder seen on the rotary table primarily comes from the feeder system — the part responsible for delivering granules into the dies during compression.

In all types of tablet press machines, whether equipped with an open-grid feeder or a closed forced feeder, there is always a small amount of powder leakage. This happens because the feeder sits directly above the rotary turret, and there is always a gap between the feeder and the table surface.

This gap is both necessary and problematic. It allows the turret to rotate smoothly without friction, but it also creates an escape path for fine powder particles. These particles accumulate over time, forming the visible residue engineers notice after continuous operation.

2. Why the Gap Cannot Be Completely Eliminated

At first glance, one might think: If powder leakage occurs through the gap, why not simply eliminate the gap?

However, in mechanical design, that’s neither practical nor safe. Both the turret and the feeder are made of metallic materials — typically iron and stainless steel. If these two components fit together with zero clearance, the high-speed rotation of the turret would cause metal-to-metal friction.

This friction could result in heat generation, surface wear, and even metal particles contaminating the tablets — a direct violation of cGMP (Current Good Manufacturing Practice) standards. In pharmaceutical production, any contamination from iron or steel particles is strictly unacceptable, as it compromises both product safety and quality compliance.

On the other hand, if the gap is made too wide, the powder leakage increases significantly. This creates a trade-off:

A smaller gap reduces powder residue but increases friction risk.

A larger gap avoids friction but allows more powder to escape.

Thus, the presence of powder residue is essentially a natural consequence of mechanical tolerance — an unavoidable result of balancing machine protection with production hygiene.

3. The Role of Centrifugal Force in Powder Scattering

Beyond the feeder gap, another key reason for powder residue lies in the centrifugal force generated during the high-speed rotation of the turret.

As the turret spins, granules within the die bores experience centrifugal acceleration. Fine particles that are not tightly compacted can be thrown outward, escaping from the die cavities before compression occurs.

This phenomenon becomes more pronounced when:

The machine operates at high rotation speeds

The granule flowability is poor

Or the granule moisture content is too low.

These flying powder particles eventually settle on the turret surface, contributing to the visible powder buildup that engineers frequently observe.

Moreover, this dispersion of powder can lead to inconsistent tablet weights, since the material available for each punch to compress is slightly reduced. In mass production, this may cause tablets to deviate from target weight specifications, affecting uniformity and quality control.

4. Why the Problem Is Unavoidable — and How to Minimize It

From a practical engineering perspective, completely eliminating powder residue is impossible. The mechanical structure and physical laws at play make it an inherent part of tablet compression. However, with proper design and operation, the problem can be minimized effectively.

Here are several ways manufacturers and engineers mitigate powder residue:

4.1. Precision Machining of Components

By improving machining accuracy, especially the flatness of the turret and feeder surfaces, the gap can be controlled within the optimal range — minimizing leakage without creating friction.

4.2. Enhanced Feeder Design

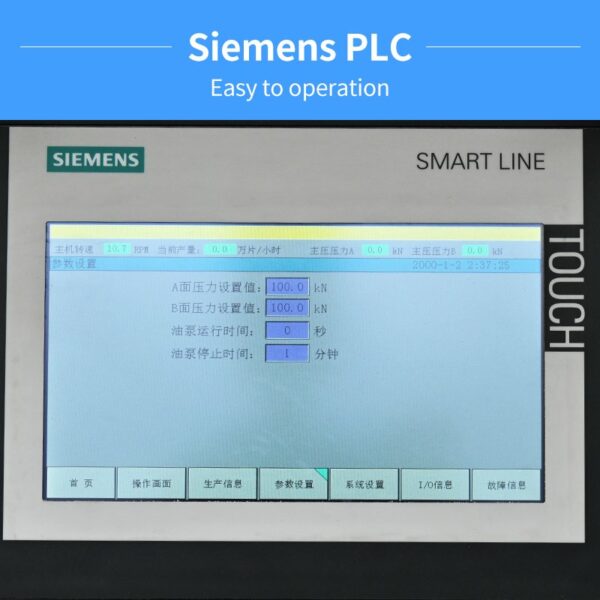

Modern tablet presses use forced feeders with adjustable scrapers and seals that reduce powder loss. Some advanced models also incorporate vacuum-assisted dust removal to maintain a cleaner environment.

4.3. Material Optimization

Using high-quality stainless steel (SS304 or SS316) components ensures smoother surface contact, less wear, and lower powder adhesion — extending the machine’s lifespan and cleanliness.

4.4. Controlled Production Speed

Operating the machine at a suitable rotation speed can reduce centrifugal scattering. Excessive speed often worsens powder ejection, while moderate speed maintains stability and product consistency.

4.5. Post-Compression Cleaning and Dedusting

Integrating a tablet deduster immediately after compression helps remove loose powder from tablets and the surrounding equipment, ensuring a cleaner working area and better product appearance.

5. Impact on Product Quality and cGMP Compliance

While powder residue might look like a cosmetic issue, it has deeper implications for pharmaceutical manufacturing standards.

Powder buildup can interfere with tablet weight consistency, die filling efficiency, and machine lubrication. Therefore, maintaining cleanliness around the turret area is vital to meet cGMP requirements and to ensure tablet quality, safety, and accuracy.

Regular maintenance — including vacuum cleaning, turret wiping, and die lubrication — not only reduces residue but also prevents long-term wear of critical machine parts.

Additionally, the use of complementary equipment such as a tablet deduster, metal detector, tablet counting machine, and blister packing machine ensures that each stage of production meets both safety and visual quality expectations. These devices form a complete tablet production line, optimizing hygiene and efficiency.

6. R&D Perspective: Reducing, Not Eliminating

At Ruidapacking, our R&D team continuously refines the design of rotary tablet presses to minimize powder residue through precision manufacturing, feeder optimization, and advanced surface treatments.

However, from an engineering standpoint, this issue can only be reduced, not eradicated. Even the world’s most advanced automatic tablet press machines exhibit some degree of powder residue due to unavoidable mechanical clearances and centrifugal dynamics.

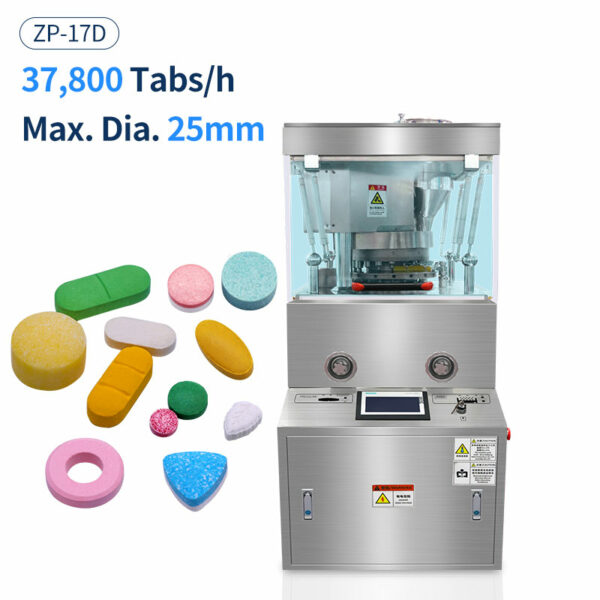

Rather than chasing an impossible “zero powder” goal, our focus is on controlled residue management — achieving a balance between machine durability, cGMP compliance, and tablet quality stability. This is the philosophy behind the continuous improvement of models such as the HGZP-15/20D, HGZP-26/40D, and other Ruidapacking tablet presses.

7. Conclusion: The Science Behind the Residue

In summary, the powder residue found on a rotary table is not a defect but a natural byproduct of the tablet compression process.

It results mainly from two causes:

1. Powder leakage through the feeder-turret gap, which cannot be completely sealed due to mechanical safety constraints.

2. Centrifugal scattering of granules during high-speed rotation, which dislodges fine particles from the dies.

Although it cannot be completely prevented, powder residue can be minimized through engineering precision, material selection, feeder improvements, and proper operational control. When combined with auxiliary equipment such as a pemotong tablet, metal detector, blister packing machine, and tablet coating machine, manufacturers can ensure both cleanliness and product integrity throughout the entire production line.