Dans les domaines de l'emballage pharmaceutique, nutraceutique et alimentaire, la précision du remplissage des poudres n'est pas seulement un objectif, c'est un impératif réglementaire. Deux technologies dominantes : le remplissage par vis sans fin et le remplissage pneumatique, offrent des voies distinctes vers l'efficacité. Analysons leurs différences selon quatre dimensions essentielles.

1. Principe de fonctionnement

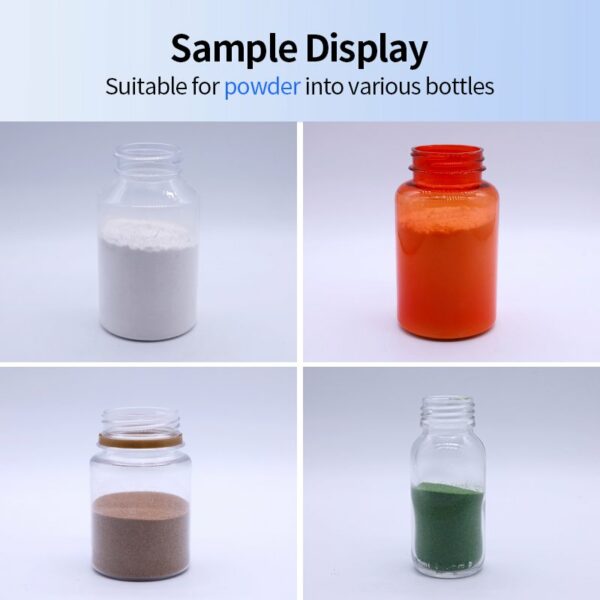

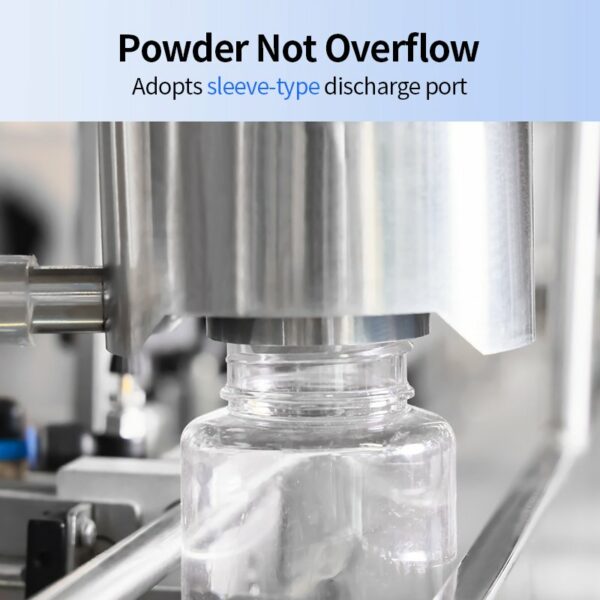

Remplissage par vis sans fin : une vis hélicoïdale rotative est utilisée à l'intérieur d'une chambre pour déplacer la poudre. La rotation de la vis déplace la poudre volumétriquement vers la buse. Des servomoteurs contrôlent la vitesse et les degrés de rotation, permettant des micro-ajustements pour un dosage précis. Idéal pour les poudres fluides à moyennement cohésives (par exemple, protéines, épices, principes actifs).

Remplissage pneumatique : Repose sur les différences de pression d'air. Un vide aspire la poudre dans une chambre de mesure, qui utilise ensuite de l'air comprimé pour la projeter dans les récipients. Fonctionnement par séquences de vannes temporisées, ce qui le rend particulièrement adapté aux poudres ultrafines et non aérées (par exemple, farine, talc).

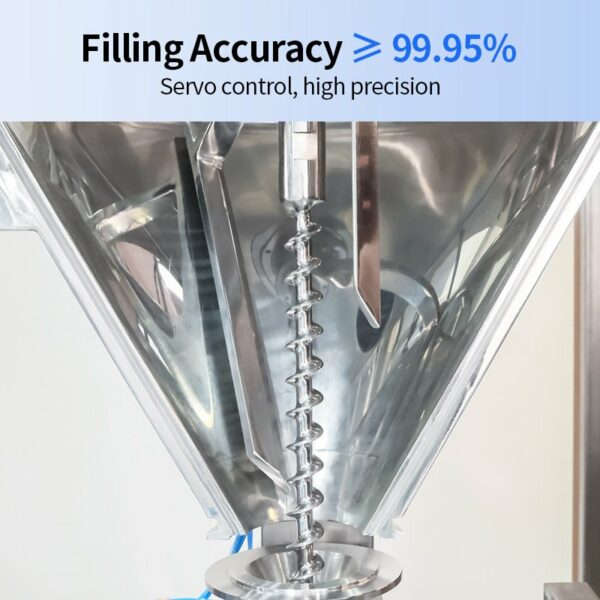

2. Précision

Systèmes à vis : précision de ± 0,51 TP3T ou supérieure grâce à la servocommande. Les cellules de charge permettent un remplissage gravimétrique, s'adaptant en temps réel aux variations de densité de la poudre. Indispensable pour les produits à forte valeur ajoutée (par exemple, préparations pour nourrissons, médicaments oncologiques).

Systèmes pneumatiques : ils atteignent généralement une précision de ±1–2%. Sensibles à l'aération de la poudre, à l'humidité et aux variations de granulométrie. Idéals pour les applications où un léger surremplissage est acceptable (par exemple, produits chimiques industriels, ingrédients alimentaires en vrac).

3. Application

Remplisseurs à vis

Poudres cohésives (collagène, cacao)

Mélanges à densité mixte

Poudres poussiéreuses/aérables (en raison du confinement à vis scellé)

Composés hygroscopiques ou volatils

remplisseuses pneumatiques

Poudres fluides et sans emballage

Particules de taille uniforme (par exemple, sel, sucre)

Applications à faible valeur ajoutée et à grande vitesse

4. Entretien et nettoyabilité

Remplisseurs à vis

Avantages : La conception modulaire permet un échange rapide de la vis et de la trémie. Compatibilité totale CIP/SIP. Les pièces de contact en acier inoxydable résistent à la corrosion.

Inconvénients : Les vis s'usent avec des poudres abrasives (minéraux), nécessitant un remplacement périodique.

remplisseuses pneumatiques

Avantages : Moins de pièces mobiles réduisent les pannes mécaniques.

Inconvénients : Les valves et les joints se dégradent sous l'effet de l'abrasion de la poudre. Difficile à désinfecter complètement (poussière emprisonnée dans les conduites d'air). Inadapté aux environnements cGMP.

Conclusion

Pour les marques pharmaceutiques, nutraceutiques ou alimentaires haut de gamme, les systèmes de remplissage à vis constituent un choix incontournable. Leur précision servocommandée, la flexibilité des matériaux et leur conception conforme aux normes garantissent l'intégrité du produit et sa conformité réglementaire. Le remplissage pneumatique est adapté aux secteurs du vrac à haute cadence et à faible précision, mais il rencontre des difficultés lorsque les marges et les exigences se resserrent.

Choisissez le remplissage à vis lorsque : vos poudres varient, vos tolérances sont serrées et votre marque ne peut pas se permettre de compromis.

Envisagez le pneumatique lorsque : la vitesse l'emporte sur la précision et que votre poudre se comporte de manière prévisible.

Dans la quête de remplissages de poudre parfaits, la bonne technologie ne consiste pas seulement à déplacer le produit, mais à protéger votre réputation, une dose à la fois.