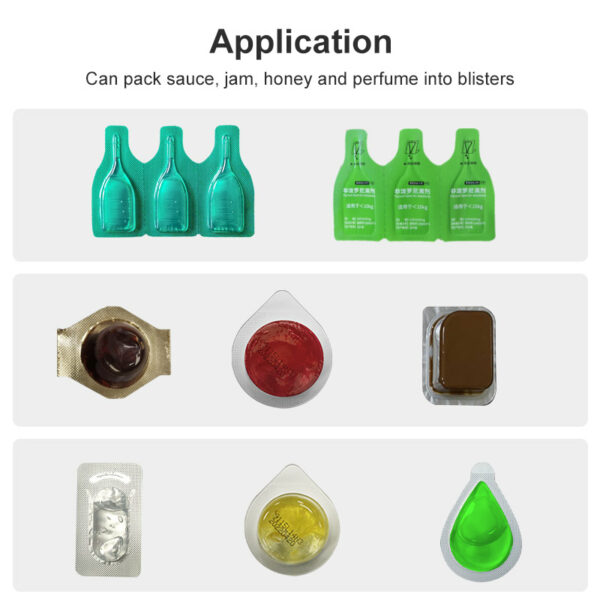

Machine d'emballage sous blister pour confitures

Machine de mise sous blister pour miel avec fonctions entièrement automatiques de formage, d'alimentation, de scellage, de poinçonnage, de comptage et de codage des numéros de lot. Elle permet de sceller automatiquement parfums, confitures et miel dans un panneau composite aluminium-plastique ou une plaque d'aluminium. Idéale pour emballer vos produits de manière efficace et économique.

Spécification:

Jusqu'à 9 600 ampoules/h

Applicable pour parfum, confiture, miel…

Livraison rapide en 15 jours

Convient aux matériaux PVC, PS et PET