Machine de remplissage de capsules Encapsuladora

Encapsuladora capsule filling machine significantly increase production speed, filling hundreds or thousands of capsules per minute, making them ideal for large-scale production.

Advanced dosing mechanisms ensure consistent filling weights and minimize material wastage, maintaining product quality.

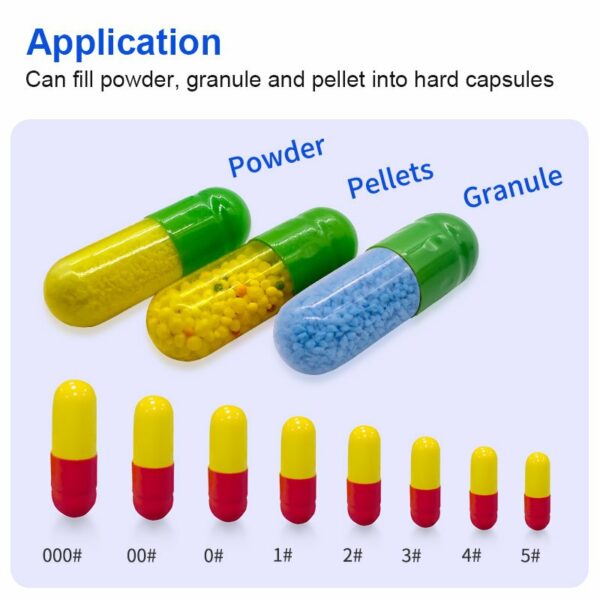

These machines can handle a wide range of materials, including powders, granules, pellets, and liquids, and accommodate various capsule sizes (#000, #00, #0, #1, #2, #3, $4, #5).

Integrated systems for detecting and rejecting defective capsules ensure high-quality output and compliance with regulations.

These advantages make capsule filling machines essential in the pharmaceutical, nutraceutical, and supplement industries.

Spécification:

72 000 capsules/h

Convient à la capsule #000-5

Conception modulaire, changement de moule 15 min