Ligne de remplissage et de comptage de capsules

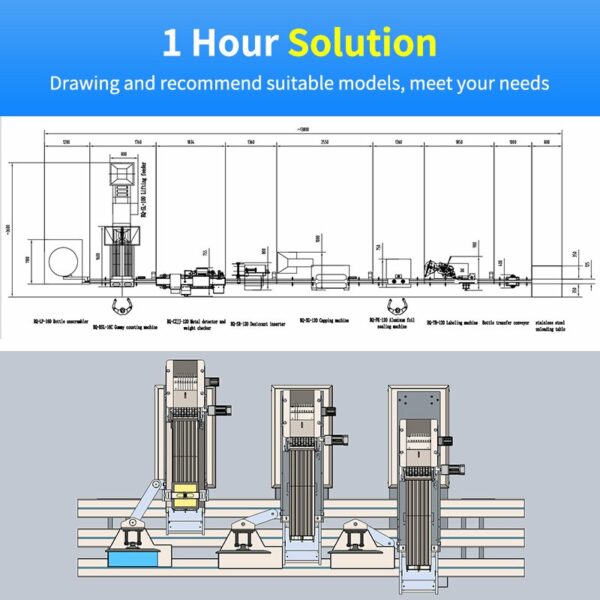

Ligne de remplissage pour le comptage de gélules comprend plusieurs étapes clés qui automatisent le processus de comptage, de remplissage et de fermeture des récipients (tels que des bouteilles ou des pots) avec un nombre précis d'articles, tels que des comprimés, des capsules ou des gels mous.

Chargement : Les produits en vrac (comprimés, gélules, etc.) sont chargés dans une trémie ou un alimentateur. Cette trémie contient le produit avant qu'il ne soit compté et distribué.

Capteurs photoélectriques : Ces capteurs comptent les produits en fonction de leur mouvement à travers un faisceau lumineux.

Mécanisme de bouchage : En fonction du produit et du type de récipient, la machine peut utiliser une capsule à vis, un système de bouchage par pression ou un scellement par induction pour sceller les récipients en toute sécurité.

Étiquetage (en option) : Certaines lignes d'embouteillage de comptage intègrent également des stations d'étiquetage, où des étiquettes sont automatiquement apposées sur les récipients remplis et scellés à des fins de marquage et de réglementation.

Spécification:

Jusqu'à 70 bouteilles/min

Livraison sous 15 jours

Convient aux comprimés, gélules, gommes de 3 à 40 mm...