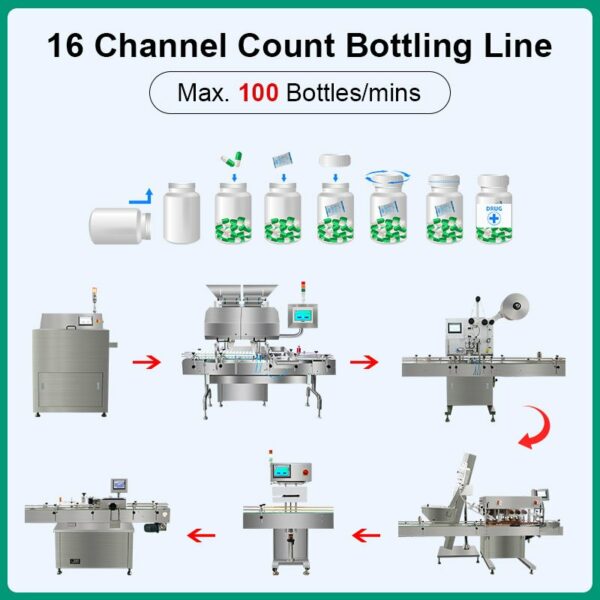

Ligne de production de comptage de capsules et de comprimés

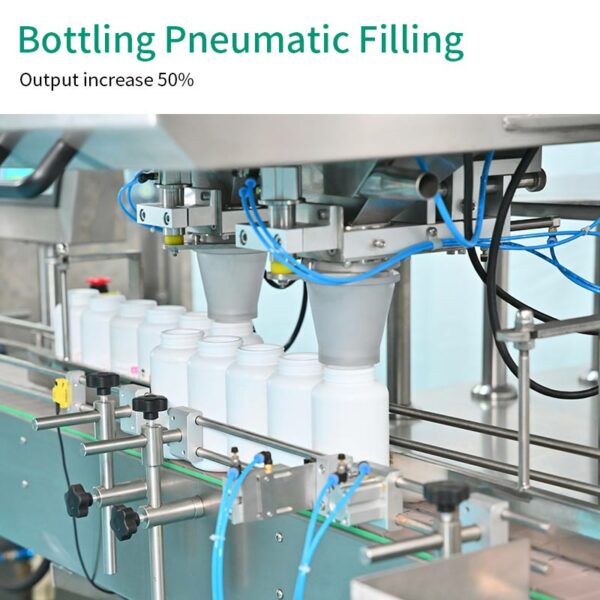

Capsule and tablet counting production line is an integrated system designed for the efficient counting, filling, and packaging of tablets or capsules in industries such as pharmaceuticals, nutraceuticals, and healthcare.

Pharmaceutical Industry: Used for packaging prescription and over-the-counter medications in tablet or capsule form.

Nutraceutical Industry: Ideal for counting and packaging vitamins, supplements, and other health-related products.

Healthcare Industry: Employed for packaging various healthcare products, including dietary supplements and herbal medicines.

Dans l'ensemble, ligne d'embouteillage de comptage is an essential solution for manufacturers looking to streamline their packaging processes while maintaining high levels of accuracy and quality.

Spécification:

Jusqu'à 100 bouteilles/min

taux de précision > 99,98%

Convient aux capsules/comprimés/gélatines de 3 à 40 mm…