Qu'est-ce que Gummy ?

Le terme « gummy » désigne généralement un type de bonbon mou et moelleux, fabriqué à partir de gélatine et souvent façonné en différentes formes, comme des oursons, des vers ou des fruits. Les gummies sont populaires pour leur texture attrayante et leur grande variété de saveurs.

Bonbons mous en raison de leur valeur élevée et de leur viscosité, emballage riche afin de pouvoir compter avec précision les bonbons, machine de comptage de bonbons spécialement développée.

Qu'est-ce que la machine à compter les bonbons gélifiés ?

Machine à compter les bonbons gélifiés Il s'agit d'un équipement spécialisé conçu pour compter et conditionner efficacement et précisément les bonbons gélifiés et les compléments gélifiés. Il peut compter des quantités de pectine, de surga, d'huile et de sable de 3 à 40 mm dans différentes bouteilles, avec une cadence maximale de 50 à 100 bouteilles par minute.

Comment résoudre le problème du comptage des bonbons gélifiés ?

Le comptage et l'emballage des bonbons avec une machine électronique traditionnelle sont plus faciles à assembler, ce qui permet de varier le nombre de bouteilles. Si vous en avez plus, vous ne sentirez rien, mais si vous en avez un ou deux de moins, vous aurez l'impression que le fabricant vous trompe. Il vous promet beaucoup, mais en réalité, il y en a un peu moins. Afin de résoudre le problème du comptage précis des bonbons, nos techniciens ont mis au point cinq innovations techniques. machine de comptage automatique, qui peuvent résoudre ce problème. Voici une brève description des cinq innovations technologiques majeures :

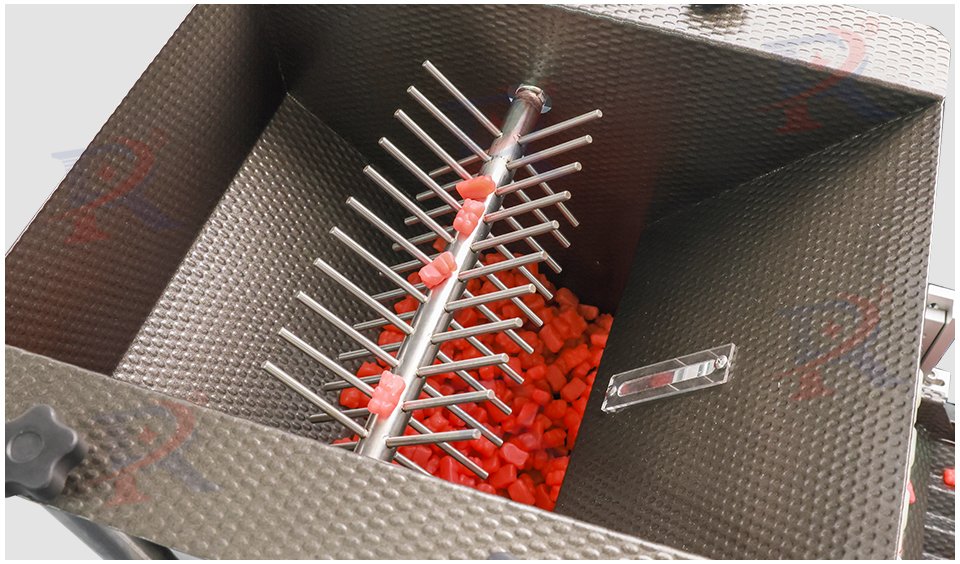

1. Séparateur à rouleaux à trémie

Une fois fabriqués, les bonbons sont tous regroupés dans un grand sac. Une fois achetés, ils sont tous emballés individuellement. Pour compter et emballer soigneusement un grand sac de bonbons, il faut d'abord séparer les bonbons en blocs. Le comptage automatique ne fait pas exception. Notre innovation consiste à ajouter un dispositif de séparation à l'orifice d'alimentation de la machine, avant que les bonbons n'entrent dans le canal de comptage. Ce dispositif agit comme une tête de mélange pour séparer les bonbons qui tombent. Bien sûr, des fuites peuvent survenir et certains bonbons ne sont pas complètement séparés. Mais rassurez-vous, il s'agit de la première innovation de la machine de comptage de bonbons pour la viscosité des bonbons mous.

Si votre production est relativement importante, l'alimentation manuelle est certainement trop tardive ou peu pratique, cette fois utilisera le chargeur de levage, nous avons également modifié la position d'alimentation du chargeur de levage, plus un filet, la surface de ce filet est revêtue de Téflon, conformément aux exigences de production de qualité alimentaire, la grille est personnalisée en fonction de la taille des bonbons, si vous craignez que la séparation ne soit pas suffisamment approfondie, vous pouvez remettre les bonbons dans la grille. Dispersez-les, puis ajoutez-les au port de décharge de la machine de comptage via le chargeur de levage.

2. Pièce coulissante pneumatique

Lorsque les bonbons passent par la trémie vers le bas dans le canal de comptage avant la conception d'un curseur pneumatique pour certains des bonbons et se collent ensemble pour se disperser, ce curseur pneumatique est connecté à un tube alimentaire, de gauche à droite d'avant en arrière, lorsque les bonbons à travers la vibration du mouvement vers le bas du tube alimentaire à nouveau pour séparer les bonbons, et une fois de plus pour s'assurer que les bonbons ne sont pas tachés ensemble.

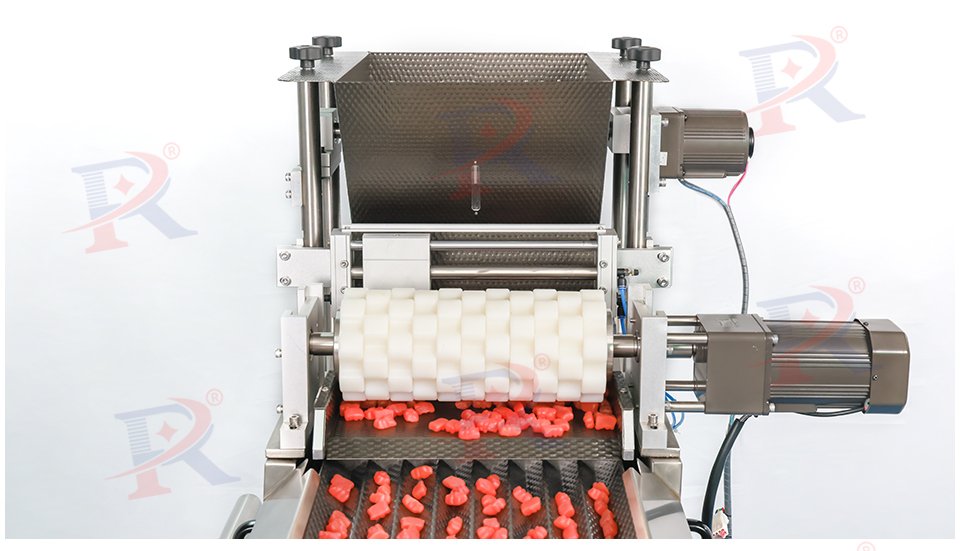

3. Système anti-agglomérant gommeux

Le système anti-agglutination est l'un des éléments clés de la conception. L'ensemble est en PTFE, sans contact avec la machine. La surface du rouleau présente une répartition hiérarchique des trous, adaptés à la taille et aux caractéristiques de chaque bonbon. La présence de gomme dans le canal de vibration peut entraîner un comptage imprécis des grains, ce qui constitue l'élément clé de la conception de la machine à compter les bonbons.

La conception du rouleau est telle que chaque trou ne peut traverser qu'un seul bonbon, pour garantir que les bonbons qui n'ont pas été séparés se séparent complètement, lorsque deux bonbons collent ensemble, la surface du rouleau et la plaque vibrante entre la pression seront générées, pour séparer les bonbons qui sont collés ensemble, pour garantir que les bonbons entrant dans le canal de vibration sont séparés un par un.

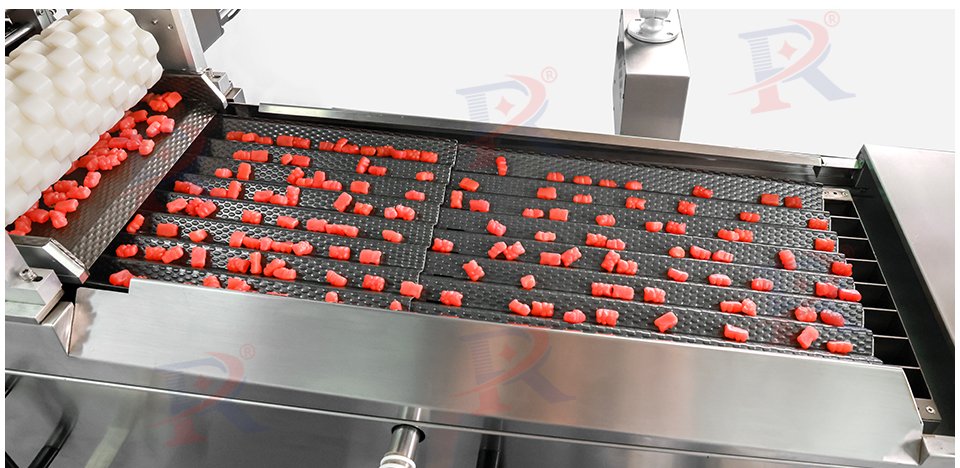

4. Téflon + canal de vibration à fossettes

En pénétrant dans le canal de vibration, la plaque vibrante est recouverte de Téflon, un matériau à très faible tension superficielle offrant d'excellentes propriétés antiadhésives. Les bonbons qui y sont déposés ne recollent pas. De plus, la plaque vibrante présente une surface irrégulière, réduisant ainsi la surface de contact entre les bonbons et la plaque, améliorant ainsi ses propriétés antiadhésives.

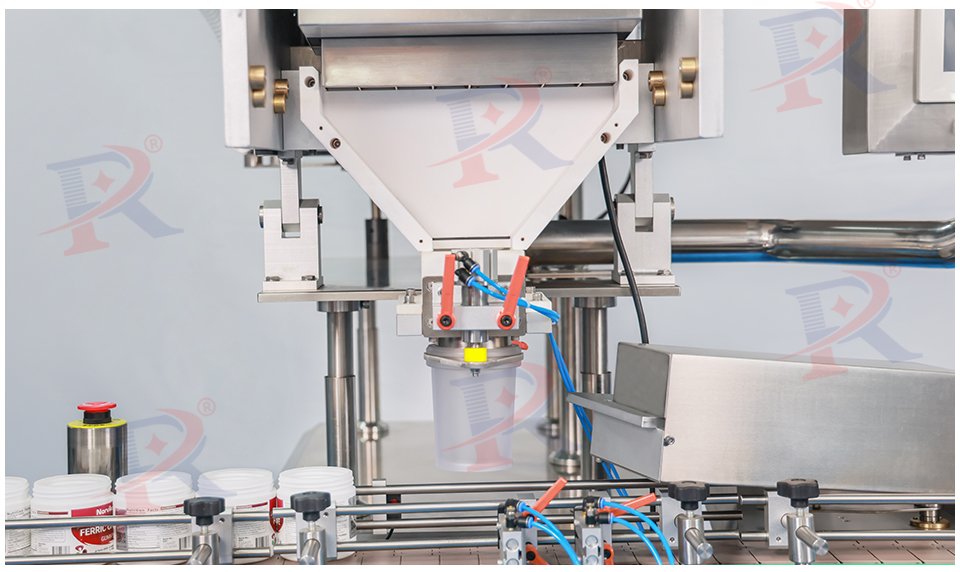

5. Port d'embouteillage en PTFE élargi

La dernière conception concerne la position d'embouteillage, avec une forme octogonale inversée en PTFE. Une observation attentive permet de constater que la sortie de la machine à compter les gélules est non seulement différente, mais aussi plus grande. En effet, la tête de la bouteille étant initialement plus grande, si le nombre de bonbons par bouteille est plus élevé, l'ouverture ne suffit pas à remplir la bouteille, ce qui affecte la vitesse et la précision de l'embouteillage.

La buse de décharge est également en PTFE, en raison du problème d'adhérence des bonbons, la bouche de décharge est relativement petite, ce qui peut entraîner un colmatage de la bouche de décharge, lorsque la bouteille entre dans la position désignée, la buse de décharge fixe la bouteille, et lorsque le bonbon descend, il vibre constamment, de sorte que le bonbon peut être lisse et rapide à la bouteille.

La tendance des machines à compter les bonbons gélifiés

La tendance des machines à compter les bonbons gélifiés reflète les progrès technologiques et l’évolution des demandes de l’industrie.

1. Automatisation accrue

Utilisation de la robotique et de l'intelligence artificielle pour améliorer la précision et l'efficacité. Les algorithmes d'IA peuvent améliorer la précision du comptage et détecter toute irrégularité dans les bonbons gélifiés.

2. Personnalisation et flexibilité

Les machines sont conçues pour traiter une large gamme de formes, de tailles et de formulations de bonbons gélifiés, ce qui les rend polyvalentes pour différentes gammes de produits. Leurs fonctionnalités permettent des changements rapides et faciles entre les différents produits afin de minimiser les temps d'arrêt.

3.IoT et Industrie 4.0

Intégration de la technologie IoT (Internet des objets), permettant aux machines de communiquer avec d'autres équipements et systèmes pour un fonctionnement transparent et un échange de données en temps réel.

Si vous avez plus d'informations sur la machine à compter les oursons en gélatine, veuillez nous contacter Emballage riche.