Vous recherchez des équipements pharmaceutiques et d'emballage en Chine, tels qu'une machine de remplissage de gélules, une machine à presser les comprimés, une machine à emballer les comprimés sous blister ? Vous savez que des enjeux existent : La qualité affecte la conformité aux BPF ; les temps d'arrêt ruinent la productivité des pilules et des gélules, et un mauvais support ralentit la production de médicaments. Fort de 20 ans d'expérience dans l'achat de machines pharmaceutiques, j'ai rédigé ce guide pour vous aider à trouver un fournisseur chinois d'équipements pharmaceutiques fiable et à éviter les pièges avant d'acheter des machines à comprimés.

1. L'industrie chinoise des équipements pharmaceutiques et d'emballage : Ampleur, défis et évolution

L'industrie pharmaceutique chinoise est un mastodonte mondial, soutenu par un vaste marché intérieur et des exportations internationales croissantes d'ingrédients pharmaceutiques actifs (API). On estime que plus de 7 000 entreprises pharmaceutiques opèrent dans le pays, allant d'énormes entités appartenant à l'État à des acteurs de taille moyenne et à un grand nombre de petits producteurs de médicaments génériques, d'après le rapport statistique annuel publié par le ministère de l'agriculture et de l'alimentation. Administration nationale des produits médicaux.

Cette base de production massive est soutenue par un écosystème tentaculaire de fabricants d'équipements pharmaceutiques. Des sources crédibles font état de plus de 1 000 entreprises nationales fabriquant divers types d'équipements de traitement pharmaceutique, de machines d'emballage et de systèmes connexes, notamment machines de remplissage de gélules, Machines à comprimés, presses à comprimés, machines à emballer les gélules sous blister, machines à emballer les boîtes en carton, machines à sceller verticales, machines à compter les gélules. et les machines d'enrobage de comprimés.

La taille du marché chinois a dépassé celle de l'Allemagne, ce qui en fait le deuxième marché mondial.nd le plus grand fabricant d'équipements pharmaceutiques et d'emballage. On estime que cette taille dépassera les 90 milliards CNY (≈12,5 milliards USD) en 2025, d'après “Rapport sur l'industrie chinoise des équipements d'emballage pharmaceutique, 2021”.

Plusieurs caractéristiques définissent ce secteur d'équipement :

1.1 Le paysage fragmenté et le défi de la concentration

Le secteur reste très fragmenté, dominé par de nombreuses petites et moyennes entreprises (PME). Cela entraîne des défis importants en matière de normalisation et de cohérence de la qualité. On assiste à une consolidation, mais les niveaux de concentration sont encore très inférieurs à ceux des marchés matures comme l'Europe ou les États-Unis.

1.2 Avancement de la technologie et déficit d'innovation

Les capacités de fabrication ont considérablement progressé au cours de la dernière décennie. De nombreux fabricants produisent désormais des équipements qui répondent aux exigences de base des BPF. Toutefois, un fossé critique persiste en matière d'innovation de pointe et d'originalité des technologies de base. Les innovations véritablement révolutionnaires des technologies de base, en particulier dans le domaine du traitement aseptique complexe et à très grande vitesse, restent concentrées chez les principaux acteurs internationaux. L'ingénierie inverse et l'adaptation de conceptions établies sont encore des voies courantes pour de nombreux fournisseurs chinois.

1.3 Dynamique de la réserve de talents

Le vivier de talents techniques est important, reflétant la solide base de formation en ingénierie de la Chine. Cependant, il y a une pénurie notable de spécialistes très expérimentés ayant une expertise approfondie des principes avancés de l'ingénierie pharmaceutique, de l'automatisation de pointe, en particulier de l'intégration de Pharma 4.0, des protocoles de validation rigoureux (IQ/OQ/PQ), et de la compréhension des paysages réglementaires complexes au niveau mondial.

1.4 Ambition du fabricant et trajectoire de la qualité

L'ambition de développement des fabricants est généralement élevée. De nombreux fournisseurs chinois de premier plan et de niveau intermédiaire investissent de plus en plus dans des installations de fabrication de pointe. La qualité des machines de traitement et d'emballage des gélules est sur une trajectoire ascendante, mais la variabilité reste un sujet de préoccupation. Alors que les fabricants chinois de premier plan produisent des équipements (par exemple des machines de remplissage de gélules pharmaceutiques, des presses à pilules), les performances et la longévité des équipements provenant de la longue traîne de fournisseurs plus petits peuvent être irrégulières, ce qui a un impact sur l'ensemble de l'industrie.

1.5 Défis liés à la qualité des équipements

Suivant la trajectoire de la qualité, les équipements pharmaceutiques et d'emballage fabriqués en Chine doivent encore relever certains défis en matière de qualité par rapport aux références mondiales.

●Défauts de finition des surfaces: L'équipement partiel présente des processus de polissage et de meulage grossiers, avec des bavures visibles sur le point de soudure en acier inoxydable, ce qui compromet la propreté et la résistance à la corrosion.

●Schéma d'ingénierie non standardisé: Les risques récurrents en matière de sécurité comprennent la disposition désordonnée des conduits, la conception incorrecte de la ventilation thermique du moteur (par exemple, face à des zones sujettes à la poussière) et l'absence de couvercles d'étanchéité sur une machine à compter les gélules et les comprimés, ce qui accroît les risques de contamination croisée.

●Respect incohérent des normes: Malgré les déclarations d'adhésion aux BPF, des détails critiques tels que les spécifications de courbure du rayon et le soudage sans espace mort ne sont pas rigoureusement mis en œuvre.

2. Principaux risques liés à l'achat de machines pharmaceutiques en Chine

Alors que les fabricants mondiaux de produits pharmaceutiques se tournent de plus en plus vers les fournisseurs chinois pour obtenir des équipements de remplissage de gélules et des presses à pilules rentables, les risques systémiques menacent de compromettre la prise de décision. Bien que les capacités industrielles de la Chine se soient accrues, il est essentiel de faire preuve de diligence raisonnable pour éviter les perturbations opérationnelles et les coûts cachés.

acheteurs sélectionnant des équipements d'emballage pharmaceutique auprès des fournisseurs

2.1 Le mirage des spécifications surévaluées

Les fournisseurs commercialisent souvent des machines de remplissage de gélules de gélatine dure vides ou d'autres équipements avec des paramètres de performance exagérés qui ne sont pas étayés par des conditions réelles. Les fausses déclarations les plus courantes sont les suivantes :

●Prétentions de production gonflées: Une machine de remplissage de gélules en poudre annoncée pour une capacité de 150 000 gélules par heure peut ne fonctionner qu'à une capacité de 60% en raison de limitations dans la manutention des matériaux.

●Théorie et réalité Compression La force: Pilule Les presses à comprimés dotées d'une force de compression principale de 150kN supportent souvent des forces nettement inférieures pendant le pressage à grande vitesse des comprimés, ce qui entraîne une mauvaise compaction, en particulier pour les comprimés effervescents de grand diamètre.

●Adaptabilité non validée: Une petite machine de remplissage de gélules commercialisée comme “polyvalente” échoue sous des formulations spécifiques telles que le remplissage de gélules de taille 5.

En raison d'une publicité exagérée, les conséquences peuvent être désespérées : goulots d'étranglement dans le conditionnement des pilules et des gélules, rejet de lots de gélules non qualifiées et incapacité à atteindre le rendement prévu pour le comptage des gélules.

2.2 Les False Philosophie de l'ingénierie orientée vers les coûts

De nombreux fournisseurs d'équipements pharmaceutiques en Chine privilégient un faible coût initial des machines, ce qui entraîne des compromis en matière d'ingénierie :

●Déficiences structurelles: Par exemple, le fait de ne pas spécifier l'épaisseur de l'acier inoxydable dans les châssis des machines à comprimés ou d'utiliser des alliages de qualité inférieure dans une machine à blister accélère la fatigue du matériel, ce qui risque d'endommager l'équipement.

●Défauts de conception critiques: Par exemple, le carter de came non intégré d'une machine à emballer les comprimés sous blister induit des vibrations et du bruit. Des systèmes de rétention de la tourelle de la presse à comprimés mal conçus permettent aux matrices de s'envoler à grande vitesse.

●Compromettre le processus de soudage: Des soudures par points au lieu de soudures à pénétration totale sur des joints porteurs compromettent la longévité d'une machine de remplissage de gélules. L'absence de traitement thermique de détente sur les engrenages ou les arbres entraîne des microfractures.

Donner la priorité au faible coût tout en négligeant les performances de la machine entraînera des temps d'arrêt imprévus, des incidents de sécurité et un coût total de possession supérieur à celui des solutions haut de gamme.

2.3 Documentation vide

Les manuels d'utilisation incomplets, mal traduits par ordinateur ou totalement absents, sont monnaie courante chez les fournisseurs chinois d'équipements pharmaceutiques. L'absence de documentation utilisable nuit à la préparation opérationnelle :

●Utilisateur manuels d'une machine de remplissage de gélules semi-automatique ou d'une machine d'emballage de gélules sous blister sont souvent mal traduites, techniquement ambiguës, ou omettent des procédures de sécurité essentielles.

●Manque de conseils vidéo complique la formation des opérateurs, ce qui augmente les taux d'erreur dans le remplissage des gélules et le pressage des comprimés.

●Aucun journal de maintenance ou arbre de dépannage accessible numériquement n'entrave l'autonomie technique.

2.4 Le service après-vente de Phantom

Un grand nombre de fournisseurs de machines d'emballage pharmaceutique en Chine se concentrent sur les ventes lucratives, tandis que leur assistance et leur service disparaissent souvent après les transactions :

●TSupport technique Abandon: La mise en service sur site est superficielle ; la formation au fonctionnement ou au protocole de nettoyage est inexistante. L'assistance à distance n'est pas réactive.

●Pièces détachées Désert: Les pièces d'usure essentielles, telles que les matrices des presses à comprimés de laboratoire, les goupilles d'éjection d'une machine d'encapsulation et les capteurs infrarouges automatiques des machines de comptage de comprimés, ne sont pas stockées localement, ce qui oblige à un délai de livraison de quatre semaines.

●Réponse différée: La promesse d'une “assistance 24/7” se transforme en un retard de service de plus de 72 heures si une fuite de poudre se produit dans une machine de remplissage de gélules à double chargement, ce qui aggrave les pertes de production de gélules de gélatine.

2.5 Fraude Substitution de Cminerai Components

En Chine, il n'est pas rare que les fabricants d'équipements de traitement des produits pharmaceutiques remplacent frauduleusement des composants de base et que des fonctions logicielles essentielles soient absentes.

●Pièces maîtresses: Les servomoteurs, les convertisseurs de fréquence, etc. d'une machine à compter les comprimés produits par des marques de renommée mondiale telles que Siemens ou Schneider sont remplacés par des marques nationales inconnues.

●Critique Mvieux: Les poinçons et matrices d'une machine à comprimés contiennent un revêtement électrolytique ; l'outillage en contact avec les comprimés de médicaments devrait être en acier inoxydable 316L alors qu'il est en fait remplacé par de l'acier standard 304.

●Défaut de logiciel: Le système de contrôle ne dispose pas d'une fonction de piste d'audit et ne répond donc pas aux exigences du 21 CFR Part 11.

3. Éviter les pièges et sélectionner judicieusement les machines pharmaceutiques auprès des fournisseurs chinois

Tout en reconnaissant les risques susmentionnés, la clé du succès réside dans la capacité à surmonter ces écueils. Alors que les chaînes d'approvisionnement pharmaceutiques mondiales intègrent de plus en plus les capacités de fabrication chinoises, le choix d'un équipement d'emballage et de traitement fiable exige une diligence méticuleuse.

3.1 Les audits d'usine vont au-delà des contrôles de surface : Le rôle essentiel de la conformité aux 6S

Effectuer des inspections inopinées sans rendez-vous préalable et se concentrer sur le niveau de propreté de l'atelier d'assemblage, la qualité du processus de soudage et l'équipement de contrôle de la qualité. Les inspections superficielles de l'usine sont insuffisantes. Dépassez les examens photographiques en exigeant des visites virtuelles en direct ou même des visites d'atelier sur place afin de procéder à une évaluation rigoureuse :

●Logique spatiale et efficacité des flux de travail

○Scrutiniser les flux de matières entre les zones clés telles que le moulage par injection, l'usinage CNC et l'assemblage des composants de l'équipement.

○ Drapeau rouge : Des flux de matériaux encombrés, voire des retours en arrière, sont le signe d'une mauvaise gestion allégée et d'infractions aux 6S.

●Sécurité électrique et normes de câblage

Inspectez l'acheminement des câbles à la recherche de fils sous tension exposés (>50V) ou de solutions temporaires non conformes, telles que des tuyaux en PVC pendants et des conduits métalliques non mis à la terre. La conformité exige que les conduits soient fermement ancrés dans des boîtiers certifiés CEI et que des presse-étoupes de décharge de traction soient placés sur toutes les connexions mobiles des machines.

L'étape suivante consiste à faire réaliser des audits par des tiers (SGS/TÜV, par exemple) afin de vérifier spécifiquement la conformité à la norme ISO 14644-1 des conditions de salle blanche des zones de manipulation des pièces en contact avec les ingrédients, et de valider l'efficacité du confinement des poussières au moyen de tests normalisés.

3.2 Vérification Authenticité de la nomenclature

Pour vérifier l'authenticité de la nomenclature, il faut comparer la documentation du fournisseur, y compris les certificats d'analyse et les certifications de matériaux, avec les composants réels, et valider la traçabilité au moyen de numéros de série uniques ou de codes de lot.

●Composants clés: Vérifiez si les pièces clés d'une machine à comprimés ou d'une machine à blisters comprenant des servomoteurs, des systèmes PLC, des onduleurs, des contacteurs et des disjoncteurs sont produites par des marques réputées et fiables ou non.

●Systèmes d'entraînement: Exiger des photos de la plaque signalétique du moteur montrant les numéros de pièces Siemens/Baldor.

●Mécanisme de la cames: Insistez sur les schémas éclatés qui font la distinction entre les systèmes intégrés pilotés par CAM et les substituts pneumatiques. Ces derniers augmentent le risque de contamination par les particules.

●Matériaux de contact: Vérifier les certificats d'usine pour les tourelles de presses à comprimés des machines à pilules en confirmant l'acier inoxydable 316L, car l'acier inoxydable 304 se corrode avec les API acides.

3.3 Examen du portefeuille de clients

Pour évaluer rigoureusement la crédibilité d'un fournisseur de machines de remplissage de gélules ou de machines de comptage de bonbons mous, il convient d'examiner minutieusement son portefeuille de clients en s'appuyant sur des preuves documentées et en vérifiant les partenariats.

●Client Validation des cas: Demander des contrats d'achat de machines avec des prix expurgés auprès de 3 fabricants de produits pharmaceutiques similaires et effectuer une vérification téléphonique de suivi. Certains fabricants de machines automatiques de comptage de comprimés mentionnent des “clients Fortune 500” sans contexte concret. Il convient d'approfondir la question :

○Demandez des références de projets de machines à compter les gélules et les comprimés avec des ingénieurs d'usine joignables.

○Vérifier les mesures de temps de fonctionnement de la machine à compter les compteurs de comprimés à l'aide de validateurs tiers.

●Drapeau rouge: Si un fournisseur de machines pharmaceutiques n'a pas de partenariat avec des fabricants de produits pharmaceutiques ou alimentaires réputés, cela signifie qu'il n'a qu'une reconnaissance internationale limitée.

Par exemple, la ligne de remplissage de bonbons anti-blocage et la machine d'emballage de médicaments sous blister de Ruida Packing ont gagné la confiance de US Pharma, Robinson Pharma et d'autres producteurs pharmaceutiques de renommée mondiale, ce qui prouve ses excellentes prouesses en matière d'équipement et son empreinte internationale étendue en matière de services.

une ligne d'embouteillage de comptage de bonbons gélifiés dans l'atelier de Ruida Packing

3.4 Garantir le respect des délais de livraison

Gérer de manière proactive les risques de livraison en imposant une validation stricte de la disponibilité des stocks des fournisseurs de la machine de remplissage de gélules njp 1200, des échéances contraignantes pour les constructions personnalisées et une logistique préétablie pour éviter les retards.

●Vérification de l'inventaire des équipements: Demande de rapports de stock d'entrepôt vérifiés et horodatés, y compris des preuves photographiques, pour une machine standard de remplissage de gélules de plantes médicinales, machine à comprimés, ou une ligne d'embouteillage de comptage avant de passer commande, afin de confirmer la disponibilité immédiate des machines et d'éviter les fausses déclarations de stock.

●Gestion des délais de personnalisation: Pour une machine d'emballage sous blister personnalisée dont le délai d'exécution dépasse 8 semaines, vous devez appliquer des clauses de pénalité basées sur des étapes critiques, notamment l'approbation de la conception, l'acceptation par l'usine et la signature des tests, et la publication des documents d'expédition.

●Partenaire logistique L'évaluation: Exiger l'approbation préalable des partenaires logistiques du fournisseur ; mandater des fournisseurs établis comme Sinotrans pour le transport terrestre et DHL Global Forwarding pour le fret aérien, et valider leurs antécédents en matière d'expéditions de produits pharmaceutiques.

●Pénalités de retard applicables: Stipuler des pénalités de 3% de la valeur de la commande par jour pour les retards ayant un impact direct sur les délais de soumission réglementaire, explicitement plafonnées à un maximum de 15% de la valeur totale du contrat.

3.5 Documentation technique Vetting

Examiner minutieusement tous les documents afin d'atténuer les risques opérationnels et de garantir la conformité réglementaire. Les actions clés comprennent :

●Spécifications de tension: Exigez des moteurs avec deux certifications 50/60Hz (par exemple, CE/UL) pour éviter les brûlures lors des fluctuations de la tension internationale.

●Précision linguistique: Charger des ingénieurs de langue maternelle d'auditer les manuels d'utilisation, en ciblant particulièrement les traductions ambiguës de la terminologie technique ou réglementaire.

●Vidéo Orientations: Vérifier que les tutoriels vidéo qui vous guident pas à pas dans les procédures de verrouillage et d'étiquetage (LOTO) et de démontage et d'installation d'une machine à emballer les comprimés sous blister ou d'une machine à compter et à remplir les comprimés sont conformes aux exigences réglementaires locales.

●Point de contrôles: Demander des protocoles de test d'acceptation en usine (FAT) énumérant tous les paramètres de test, les critères d'acceptation et l'alignement sur les spécifications du bon de commande pour la préparation à l'audit.

3.6 Évaluation de la capacité de soutien global

Les fournisseurs d'équipements de traitement pharmaceutique fiables garantissent un accord de niveau de service de réponse ≤48 heures. Lorsque vous devez évaluer la capacité d'assistance technique mondiale des fournisseurs d'équipements pharmaceutiques afin d'obtenir une assistance technique à la mise en service dans les délais impartis, procédez à des validations :

●Mobilité des techniciens sur site: Exiger des copies des pages de visa des passeports des techniciens montrant des tampons d'entrée récents dans l'espace Schengen ou aux États-Unis afin de confirmer la capacité de déploiement transfrontalier.

●Légitimité et engagement du personnel: Valider les dossiers de sécurité sociale/impôts pour vérifier le statut d'emploi à temps plein des techniciens et ingénieurs du fournisseur, afin de réduire les risques de dépendance vis-à-vis des sous-traitants.

●Accessibilité des pièces de rechange au niveau régional: Examiner les cartes d'inventaire en temps réel des centres régionaux (par exemple, l'entrepôt de Rotterdam pour la région EMEA) pour s'assurer de la disponibilité des composants critiques et de la rapidité des livraisons.

3.7 Analyse de l'exposition : Évaluer la crédibilité des fournisseurs par le biais d'une analyse stratégique Participation à l'Expo

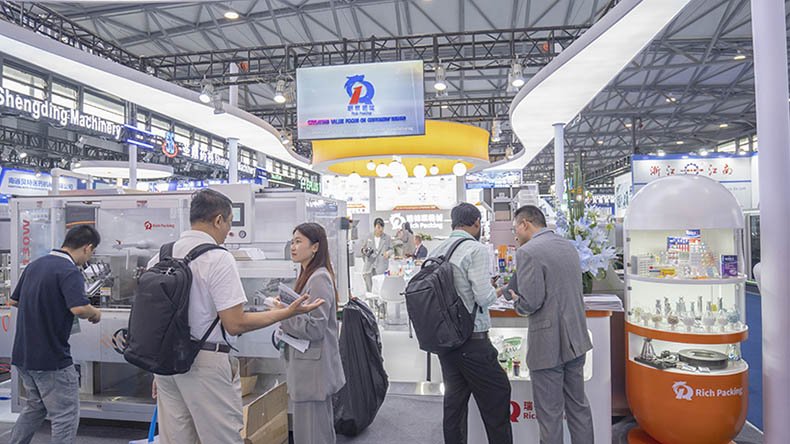

Pour les acheteurs d'équipements pharmaceutiques et d'emballage, la présence d'un fournisseur dans les salons est un indicateur essentiel de sa stature sur le marché et de ses capacités techniques. Les fournisseurs qui dominent les halls centraux des événements de niveau 1 jouissent généralement d'une plus grande stabilité financière et d'un pipeline d'innovation validé.

Donner la priorité aux fournisseurs qui obtiennent régulièrement des places de choix lors d'événements mondiaux de niveau 1 tels qu'Interpack (Core Pharma Packaging Zone : Hall 4) et CPhI Worldwide (Hall 1). En outre, procédez à une validation croisée avec les expositions régionales de niveau 2, notamment P-MEC China (API Machinery Cluster : Hall W5) et Arab Health (High-Trust Cohort : Pavillon allemand).

●Intelligence en matière de positionnement des stands : Centralité = Crédibilité

Les stands situés au coin ou à l'écart indiquent une influence commerciale ou des investissements en R&D limités.

○Les fournisseurs demandent des plans d'exposition mettant en évidence la proximité des scènes principales ou des stands des concurrents leaders du marché tels que BOSCH et IMA. Par exemple, un fournisseur voisin du groupe GEA à Interpack signale une reconnaissance technique comparable. Par ailleurs, avec un stand situé dans le hall N1 du CPhI Expo 2025, Ruida Packing a montré ses prouesses en matière de fabrication de machines, en exposant ses machines de qualité pour le traitement des pilules et des gélules et ses lignes d'emballage de gélules de comprimés aux côtés d'un certain nombre de fabricants d'équipements d'emballage pharmaceutique de premier plan.

Ruida Packing au CPhI Expo 2025

3.8 Talent Piscine Vérification : Garantir l'expertise technique des fournisseurs d'équipements pharmaceutiques

Pour atténuer les risques opérationnels liés à l'équipement, validez les capacités techniques de l'équipe d'ingénieurs de votre fournisseur. Mettez en œuvre les protocoles de vérification suivants :

●Exiger des preuves documentées des compétences de base

Exiger des CV détaillés pour les ingénieurs affectés, en vérifiant explicitement :

○≥5 ans d'expérience pratique dans la maintenance/l'optimisation des lignes de remplissage de gélules.

Formation certifiée par le TÜV sur les systèmes d'automatisation pharmaceutique.

○Compétence linguistique : IELTS 6.5+ ou certification équivalente en communication technique indispensable pour interpréter la documentation cGMP.

●Réaliser des simulations techniques en temps réel

Valider les compétences en matière de résolution de problèmes grâce à une communication vidéo en direct, par exemple en simulant une panne de servomoteur pendant le comptage à grande vitesse de gélules et de comprimés. Effectuer des diagnostics immédiats tels que la vérification du retour d'information de l'encodeur de la machine à compter les comprimés et l'analyse de la fluctuation du couple de la presse à comprimés, et examiner la réponse de l'équipe technique d'un fournisseur.

Derniers mots

En résumé, l'industrie chinoise des équipements pharmaceutiques et d'emballage est massive, dynamique et évolue rapidement. Si la fragmentation et les lacunes en matière d'innovation de base et de talents de haut niveau persistent, la forte ambition des fabricants et les améliorations continues de la qualité sont à l'origine d'une trajectoire clairement ascendante.

Pour l'industrie chinoise des équipements pharmaceutiques, combler le fossé de l'innovation et poursuivre la normalisation de la qualité au sein de la vaste base de fournisseurs sont les prochaines étapes cruciales d'une compétitivité mondiale durable. Pour les acheteurs transfrontaliers, afin d'atténuer durablement les risques liés aux fournisseurs, il convient de mettre en œuvre des protocoles de vérification validés à l'échelle mondiale, qui comprennent des audits d'usine, la vérification de l'accumulation de talents et le suivi du cycle de vie de la conformité, afin de garantir une tolérance zéro pour les écarts de production dans la fabrication de médicaments sous forme de pilules ou l'emballage de pilules sous forme de gélules.