With 15 years of industry expertise in pharmaceutical packaging machinery, Ruidapacking understands the critical importance of filling accuracy for pharmaceutical manufacturers. It directly impacts product quality, regulatory compliance, raw material costs, and production efficiency. Weight variations due to inaccurate filling can lead to significant losses, from batch waste (rework, scrapped materials) to Out-of-Specification (OOS) investigations, batch rejections, and even recalls.

Below, Ruidapacking provides an in-depth analysis of the key factors influencing capsule filling accuracy:

1. Metering Principle: The Foundation of Accuracy

Reason: Different principles (piston, cannula, dosing disc) vary in material adaptability, theoretical accuracy limits, and stability. Incorrect selection or inherent limitations can cause systematic deviations.

Piston/Ram Systems (Most Accurate & Widely Used): Accuracy depends on:

Machining precision of the metering hole/bore.

Clearance between the ram and hole.

Controllability and repeatability of ram stroke.

Sensitive to powder compressibility.

2. Precision Machining & Rigid Construction

Reason: The rigidity, machining accuracy, and assembly precision of the frame, turntable, drive system, and bearings directly impact operational smoothness and vibration. Looseness, deformation, or wear amplifies errors.

Micron-Level Tolerances: Essential for metering discs, punches, dies, and turntable bearings.

High-Performance Materials: Use of high-hardness, wear-resistant, fatigue-resistant materials (e.g., premium alloy steel, carbide) with appropriate heat treatment ensures longevity.

Precision Assembly: Strict processes, including laser alignment tools, guarantee workstation coaxiality, parallelism, and perpendicularity.

3. Advanced Motion ControlSystem

Reason: Traditional pneumatics struggle with precise position, velocity, and acceleration control, especially at high speeds. This impacts punch compression consistency, turntable indexing accuracy, filling uniformity, and sensitive material handling.

Built-in Cam Advantages (Replacing Pneumatics):

Infinitely variable speed control.

Precise position control (ram stroke depth).

Flexible pressure control (for powder compression).

Multi-axis synchronization reduce mechanical shock.

4. Materials Properties

Reason: Material physical properties (flowability, bulk/tapped density, particle size distribution, shape, compressibility, adhesion, hygroscopicity, static charge) are the most dynamic variables affecting accuracy. The machine must adapt to the material.

Poor Flowability (High Angle of Repose): Causes bridging and uneven filling.

Excellent Flowability: Can lead to segregation.

Density & Compressibility Variations: Affect weight consistency in volumetric filling; require precise compression force control.

Adhesion & Static Electricity: Cause material retention in metering holes/cannulas, leading to under-filling and discharge issues.

5. Environmental Control

Reason: Ambient temperature and humidity fluctuations affect material properties (e.g., moisture absorption impacting flowability, clumping) and equipment (metal expansion/contraction, electronic stability).

Temperature & Humidity: Crucial for sensitive APIs/excipients.

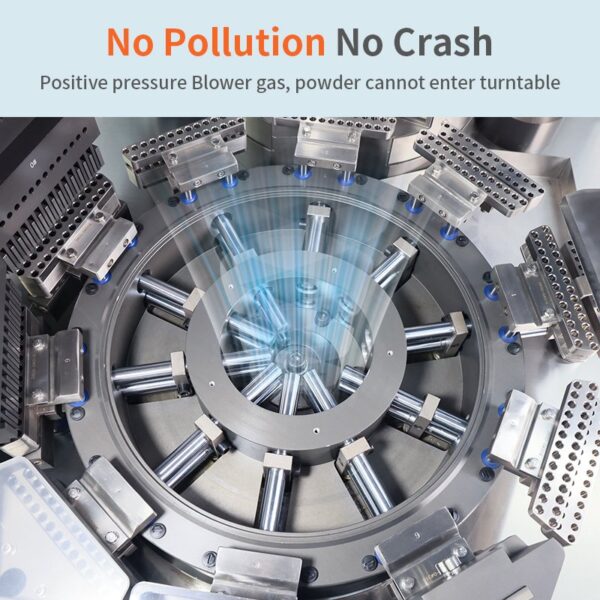

Dust: Interferes with precision components (guide rails, bearings) and load cells.

Vibration: External sources can disrupt machine operation and online weighing.

6. Equipment & Process Validation

Reason: Validation is a cGMP mandate and the systematic proof that equipment consistently produces product meeting specifications under actual conditions. It identifies and resolves potential accuracy issues.

IQ (Installation Qualification): Verifies correct installation per specifications.

OQ (Operational Qualification): Confirms all functions (metering, motion control, weighing feedback, etc.) operate correctly under no-load/simulated load.

PQ (Performance Qualification): Demonstrates consistent production of conforming product (meeting weight accuracy targets, RSD <3-5%) using actual materials and parameters.

Process Validation: Establishes a robust, repeatable process window for a specific product (material + formula + capsule size + parameters).

Abschluss

Capsule filling accuracy is not determined by a single factor. It’s a systematic integration of:

Precision Machinery: Optimal metering principle (primarily piston), micron-level manufacturing.

Power Control: Built-in cam drives, pressure-position-velocity closed loops.

Material Science: Adaptive hoppers, anti-adhesion tooling, process databases.

Environmental Management: Controlled operating conditions.

Rigorous Validation: Comprehensive cGMP-compliant protocols and data integrity.

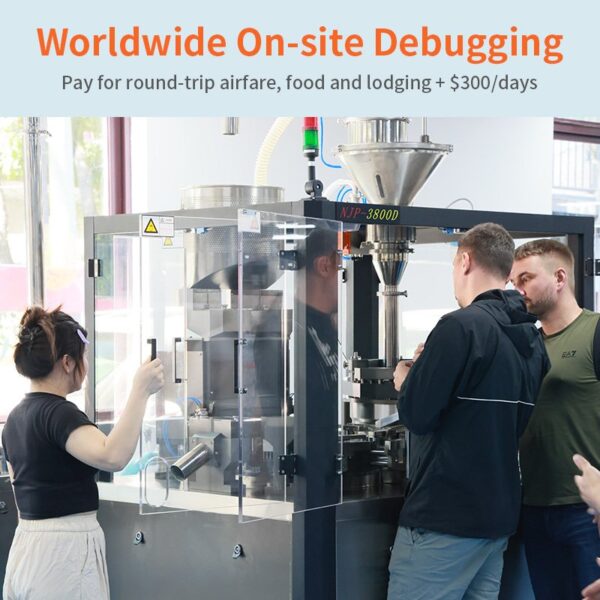

With 15 years addressing pharmaceutical manufacturers’ pain points, Ruidapacking’s high-precision capsule filling machines deliver:

Reduced Risk of weight variation failures.

Lower Material Waste and operational costs.

Increased Production Efficiency.

Smoother cGMP Compliance.

Choose Ruidapacking to transform your investment into reliable, high-quality, and safe pharmaceuticals.