- Ev

- Hazır Poşet Paketleme Makinesi

Doypack Paketleme Makinesi

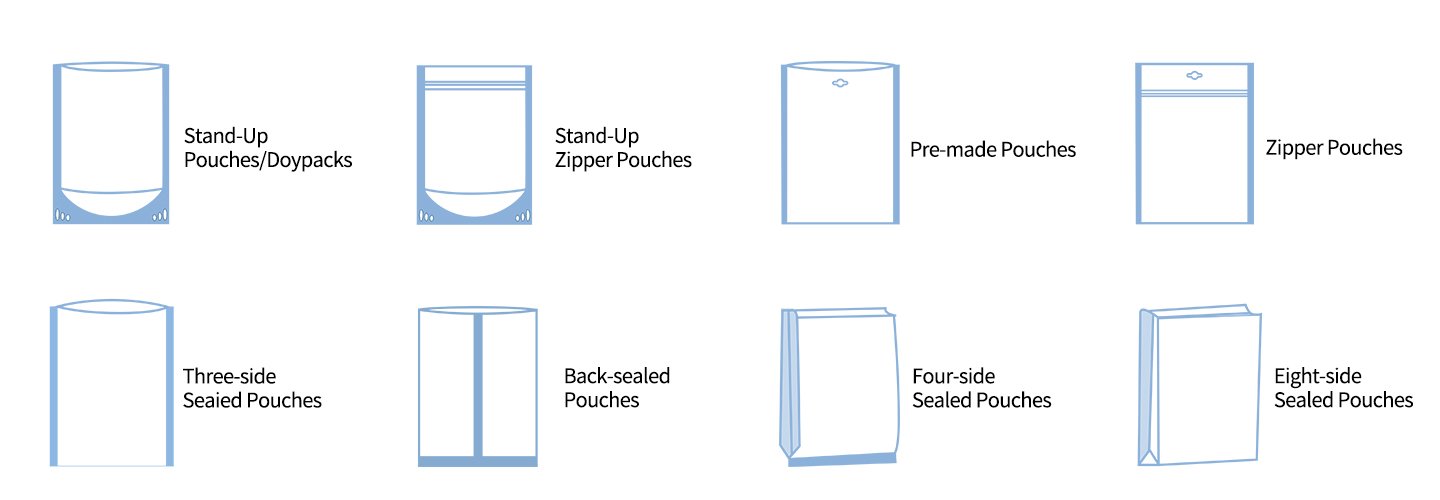

Hazır poşet paketleme makineleri, dik duran poşetlerin, düz poşetlerin ve ağızlı poşetlerin yüksek hızlı dolum ve kapatma işlemlerini otomatikleştirir. Çeşitli sektörlerde katı, sıvı ve yarı katı ürünlerin verimli bir şekilde paketlenmesi için olmazsa olmazdırlar. Başlıca uygulama alanları arasında ilaçlar (tabletler, kapsüller, tozlar), yiyecek ve içecekler (jelatinli şeker, şekerleme, atıştırmalıklar, kahve, soslar), kişisel bakım ve kozmetikler (losyonlar, şampuanlar, kremler), evcil hayvan mamaları ve kimyasallar bulunur. Bu makineler, önceden şekillendirilmiş, baskılı poşetlerin işlenmesinde mükemmeldir, hassas dozajlama, ürün bütünlüğü için sağlam sızdırmazlık ve hijyenik çalışma sunar. Orta ve yüksek üretim hacimleri için ideal olan hazır poşet paketleme makineleri, operasyonları kolaylaştırır, ürün sunumunu iyileştirir, ürün tazeliğini ve güvenliğini sağlar ve manuel işçilik maliyetlerini önemli ölçüde azaltır.

Başvuru:

Hazır fermuarlı ayakta duran poşet paketleme makinesi kapsül, sakızlı ayı, şeker, kahve gibi ürünleri çeşitli poşetlere paketleyebilir.

Her İş İstasyonunun İş Akışı

Poşet paketleme makinesi, toz, sıvı ve orta boy poşetleri dik duran poşetler ve fermuarlı poşetler gibi daha büyük poşetlere paketlemek için profesyonel, hazır poşet paketleme makinesidir. Makine, poşet toplama, kodlama, poşet açma, fermuar açma, malzeme doldurma, dozajlama, hava tahliyesi (veya tazelik için azot yıkama), poşet düzenleme, fileleme ve bitmiş ürün çıkışı gibi tam otomatik işlevler sunar.

Makine Özellikleri

Ruidapacking, GMP standartlarını karşılayan, verimli ve kullanışlı özelliklere sahip üstün kaliteli makineler üretmeye kendini adamıştır.

Geniş Uygulanabilirlik

Şekerlemeler, kuruyemişler, reçeller, tozlar, granüller, poşetler ve sıvı posalar dahil olmak üzere çeşitli malzemeleri önceden hazırlanmış torbalara paketlemek için uygundur.

Tamamen Kapalı Tasarım

Malzemelerle temas eden parçalarda kullanılan 316L paslanmaz çelik, cGMP gerekliliklerini karşılar. Yüksek su geçirmezlik derecesi, suyla kolay temizlik ve kolay bakım sağlar.

Tek Düğmeyle Ayarlama

Torba genişlik ayarı 8 çalışma istasyonu senkronizasyonu ile motor tarafından otomatik olarak yapılır ve torba değişimi 2 dakikada tamamlanır.

Teknik Parametreler

Poşetlerin boyutuna göre en iyi makineyi seçin.

| Örnek | RD-GD-200Pro | RD-GD-260Pro | RD-GD-300Pro | RD-GD-360Pro |

| Çıktı | 60 Poşet/dakika | 50 Poşet/dakika | 50 Poşet/dakika | 50 Poşet/dakika |

| Poşet Boyutu | U: 90-360 mm G: 100-220 mm | U: 150-360 mm G: 150-270 mm | U: 190-460 mm G: 200-310 mm | U: 260-510 mm G: 250-360 mm |

| Güç | 3,5 kW | 4,5 kW | 4,5 kW | 4,5 kW |

Destekleyici Ürünler

Otomatik Şişeleme Şeker Sayma Makinesi

Automatic Bottling Candy Counting Machine with its efficient and accurate counting capabilities are widely used in pharma, food, Health care ...

Otomatik İlaç Kapsül Makinesi

Automatic Pharmaceutical Capsule Machine: GMP-compliant, 90,000 capsules/h, ±1% dosing accuracy, supports 000#-5# capsules. Ideal for pharma & nutraceuticals.

Otomatik Tablet Pres Makinesi

Automatic tablet press machine involves compressing powder or granulated into uniform quality tablets through a series of precisely controlled ...

Fortune 500 Kalite Tedarikçisi

Customers Say We're Good

Get praise from SINOPHARMA, GSK, USPharma, Atlantic Grupa, Robinson Pharma…

6S Yönetimi

We check every process to ensure machines meet CE, cGMP, ROHS, FDA…

Kalıp Özelleştirilebilir

Available in different sizes and dimensions of capsules and tablets to suit your needs

Collaborative Projects

You only need to provide the blisters size, and our engineers will take care of the rest.

On-site Debugging Worldwide

Global customer service center in the United States is on standby. You should responsible for engineers’ round-trip air tickets, accommodation and meals + $350/hour

Sıkça Sorulan Sorular

Ücretsiz Özel Düzen Tasarımı: Kat planınızı optimize edin, uzman makine yerleştirme planlamasını ücretsiz edinin.

Kapsamlı Teknik Dokümantasyon ve Sorun Giderme Kılavuzları: Kılavuzlara ve yaygın sorun çözümlerine anında erişim sağlayarak kesinti süresini en aza indirin.

Gerçek Zamanlı Uzaktan Video Desteği: Karmaşık sorunların hızlı çözümü için kıdemli mühendislerle doğrudan bağlantı kurun.

Küresel Nakliye Basitleştirildi:Dünya çapında, kapınıza kadar sorunsuz DDP/DDU teslimatı.

Yerel Kurulum ve Eğitim: Sertifikalı teknisyenlerimiz tarafından yerinde kurulum, devreye alma ve operatör eğitimi. Gerçek bir gönül rahatlığı yaşayın.

Yıllık Performans İncelemesi: Ekipmanınızın her yıl en yüksek verimlilikte çalışmasını sağlamak için proaktif kontroller.

Hazır poşet paketleme hatlarında, destekleyici ekipman olarak çok başlıklı bir tartım makinesi veya tablet kapsül sakızlı şeker sayma makinesinin seçilmesinin temel kararı, işlenen malzemenin özelliklerine bağlıdır. Bu iki teknoloji belirgin avantajlar sunar ve belirli uygulamalara uygundur. Yanlış makine seçimi, verimin düşmesine, yetersiz hassasiyete, yüksek malzeme israfına ve hatta operasyonel arızalara yol açabilir.

Her cihazın seçim kriterleri, güçlü yönleri ve sınırlamaları, temel malzeme özelliklerine göre aşağıda ayrıntılı olarak analiz edilmiştir:

1. Malzeme Özellikleri

Fiziksel Form

Granüller, Pullar, Çubuklar, Parçalar (Normal/Düzensiz Katılar): Hem çok başlı tartım makinesi hem de sayım dolum makinesi olası seçeneklerdir; nihai seçim diğer özelliklere bağlıdır.

İnce Parçacık: Genellikle sayma makineleri için daha uygundur.

Tozlar, Macunlar, Sıvılar, Viskoz Malzemeler: Çok başlıklı tartımlı dolum makineleri veya otomatik sayım makineleri uygun değildir. Bunlar hacimsel dolum ekipmanları (Helezon Dolum Makineleri, Piston Dolum Makineleri, Sıvı Dolum Makineleri) veya net ağırlık terazileri gerektirir.

Bireysel Ağırlık/Boyut

Büyük ve Nispeten Tekdüze Bireysel Ağırlık: (Büyük Bisküviler, Çikolata Barları, Bütün Meyve, Oyuncak Parçaları) Çok başlı kombinasyon tartıcılar genellikle verimlilik ve maliyet etkinliği açısından avantajlar sunar.

Çok Küçük veya Çok Değişken Bireysel Ağırlıklar: (Küçük Haplar, Çekirdekler, Sakızlı Şeker, Küçük Donanım) Otomatik elektronik sayma makineleri, hassasiyet ve atığı en aza indirme konusunda mükemmeldir. Çok başlıklı tartım makineleri, çok hafif ürünler için doğruluk kontrolünde zorluk çeker ve küçük ürünler, çalışma sırasında tartım kovaları içinde "uçup gitme" (havalanma) nedeniyle kaybolmaya eğilimlidir.

2. Çok Kafalı Tartım Makineleri

Malzeme, ana titreşimli besleyiciden birden fazla (genellikle 8-24) bağımsız tartım kovasına (tartım hunisi) dağıtılır. Bir bilgisayar sistemi, her kovadaki ağırlığı sürekli olarak okur ve birleşik tartım algoritması kullanarak, toplam ağırlığı hedef ağırlığa en yakın olan kova grubunu hızla belirler. Seçilen kovalar, aynı anda alttaki bir toplama hunisine boşaltılarak malzemeyi ambalaj poşetine yönlendirir.

Avantajları

Yüksek Hız: Kombinasyon tartım prensibi, olağanüstü yüksek tartım hızlarına olanak tanır (genellikle dakikada 100-200 poşet, yüksek hızlı modellerde dakikada 300 poşetin üzerine çıkar), bu da onu üretim çıktısını en üst düzeye çıkarmak için tercih edilen seçenek haline getirir.

Yüksek Hassasiyet: Orta düzeyde bireysel ağırlıklara sahip serbest akışlı malzemeler için, çok başlıklı tartım cihazları çok yüksek tartım hassasiyetine ulaşır (malzemeye ve hedef ağırlığa bağlı olarak ±0,1 g ila ±1 g veya daha iyi). Kombinasyon algoritması, bireysel besleme değişikliklerini etkili bir şekilde telafi eder.

Geniş Ağırlık Aralığı: Hedef ağırlığı ve kova boyutunu ayarlayarak birkaç gramdan birkaç kilograma kadar değişen paketleme özelliklerini karşılayabilir, güçlü uyum yeteneği sunar.

Serbest Akışlı Malzemeler İçin İdealdir: Granülleri, pulları, parçaları ve diğer serbest akışlı malzemeleri düzgün ve verimli bir şekilde işler.

Nispeten Kolay Temizlik ve Bakım: Nispeten standart bir yapıya sahiptir; malzemeyle temas eden parçalar (titreşimli besleyici, kovalar) genellikle temizlik için çıkarılabilir.

Dezavantajları

Akışkanlığı Zayıf Malzemelerle Mücadele: Yapışmaya, topaklanmaya, yağlı veya nemli olmaya meyilli malzemeler titreşimli besleyicide, tampon haznelerinde veya tartım kovalarında kolayca tıkanabilir ve bu da dengesiz beslemeye, hassasiyetin azalmasına veya hatta makinenin durmasına yol açabilir.

Küçük/Çok Hafif Malzemelerle İlgili Zorluklar: Son derece küçük veya hafif ürünler (küçük tohumlar, küçük haplar), tartım kovaları içinde hava akışı dağılımına ("uçup gitmeye") maruz kalabilir ve bu da malzeme kaybına neden olur. Çok küçük hedef ağırlıkları için doğruluk avantajları da azalır.

Kırılgan Ürünlere Olası Hasar: Titreşimli besleyici ve kova boşaltma sistemindeki yuvarlanma hareketi, darbe ve sürtünmeye neden olabilir ve çok kırılgan ürünlere (patates cipsi) zarar verebilir.

Düzensiz/Dolaşan Malzemelerle Zorluk: Uzun, düz veya lifli nesneler titreşimli besleyici raylarına veya kova girişlerine dolanabilir veya sıkışabilir.

Ağırlığı Verir, Sayıyı Değil: Tam parça sayısını değil, hedef ağırlığı çıktı olarak verir. Kesin miktarlar (birim sayısına göre satılan ürünler) gerektiren uygulamalar için uygun değildir.

3. Elektrikli Sayma Makineleri

Şişeleme makineleri, fiziksel ayırma veya görsel tanıma teknolojisini kullanarak tek tek ürünleri ayırır ve sayar. Yaygın türleri şunlardır:

Sayma ve doldurma makinesi: Titreşimli raylar üzerinde sıralanan ürünler, fotoelektrik sensörler aracılığıyla sayılır.

CCD kamera denetim sayma makinesi: Yüksek hızlı kameralar düşen nesnelerin görüntülerini yakalar ve görüntü işleme yazılımı tek tek birimleri tanımlayıp sayar.

Avantajları

Tam Parça Sayımı Sağlar: Hassas sayım gerektiren uygulamalar (ilaçlar, sakızlı şeker, şekerleme, elektronik bileşenler) için tek çözüm.

Akışkanlığı Zayıf Malzemelerin Üstün İşlenmesi: Genellikle nemli, yağlı veya yapışkan malzemelerin işlenmesinde tıkanma riskini azaltarak çok başlı tartım makinelerinden daha iyi performans gösterir.

Küçük Peletler ile Mükemmel: Küçük hapların, tohumların ve şekerlerin yüksek hassasiyetle, düşük atıkla sayımı için idealdir.

Düzensiz Şekilleri Etkili Şekilde Ele Alır: Gelişmiş görsel sayaçlar, farklı ve zorlu geometrilere sahip öğeleri doğru bir şekilde tanımlayabilir ve sayabilir.

Düşük Malzeme Kaybı: Sayım genellikle tartım kovasının ters çevrilmesini önleyerek "uçup giden" veya ürün kalıntısından kaynaklanan kaybı en aza indirir.

Düşük Gürültü: Çok başlı tartım makinelerine kıyasla daha az titreşimli bileşen, genellikle daha düşük gürültü seviyeleriyle sonuçlanır.

Dezavantajları

Daha Yavaş Hız: Mutlak hız genellikle çok başlıklı tartılardan daha düşüktür (özellikle küçük parçalar için). Yüksek hızlı görsel sayıcılar 100-150 parçaya ulaşabilir, ancak bu, yüksek hızlı tartılara kıyasla daha düşük paketleme hızlarına (100 parçalık paketler için dakikada 60-90 poşet) dönüşür.

Ağırlık Doğruluğu Birim Tekdüzeliğine Bağlıdır: Sayım doğruluğu 100%'dir, ancak paket ağırlık doğruluğu tamamen tutarlı bireysel ürün ağırlığına bağlıdır. Önemli ağırlık farklılıkları (düzensiz boyutta kuru meyveler, kuruyemişler) paket ağırlığında büyük dalgalanmalara neden olur.

Ürün Toplanmasına Karşı Hassasiyet: İki veya daha fazla ürün birbirine yapışır ve tek ürün olarak sayılırsa, eksik sayım meydana gelir. (Çözüm Örneği: Uzman şeker tezgahımız, 4 temel özellik aracılığıyla topaklanma sorununu çözer:)

Çivili Hazne Karıştırıcı: Sakızların dikey olarak istiflenmesini önler.

Topaklanmayı Önleyici Dağıtım Silindiri: Yapışmayı önleyerek partinin eşit şekilde dağılmasını sağlar.

Teflon Çukur Paneller: Yapışkanları tamamen ayırır ve pürüzsüz, hızlı kaymayı sağlar.

Genişletilmiş PTFE Tahliye Portu: Tıkanıklığı azaltır, hızı 58%'ye kadar artırır.

Karmaşık Ekipman Seçimi: Farklı tezgah tipleri malzeme uygunluğu açısından önemli ölçüde farklılık gösterir ve optimum seçim için uzman bilgisi ve test gerektirir.

Görüntü Sayım Cihazlarının Yüksek Maliyeti: Yüksek performanslı görüntü sayım sistemleri için ilk yatırım önemli olabilir ve çoğu zaman çok başlı tartım cihazı maliyetlerini aşabilir.

Büyük/Ağır Ürünler İçin Sınırlı Kapasite: Çok büyük parçaları (bütün çikolatalar, büyük oyuncaklar) saymak genellikle yapısal olarak pratik değildir, daha yavaştır ve çok başlı tartıları kullanmaktan daha az maliyet etkindir.

4. Özet ve Ekipman Seçim Kılavuzu

| Özellik | Çok Kafalı Tartım Cihazı Önerisi | Otomatik Sayma Makinesini Önerin |

| Temel Gereksinim | Hedef ağırlık önceliğimizdir; maksimum hız ve verimliliği hedefleyin | Kesin parça sayısı önemlidir; veya malzeme özellikleri tartımı uygunsuz hale getirir |

| Malzeme Akışkanlığı | İyi (Kuru, akıcı) | Zayıf/Orta (Yağlı, nemli, yapışkan, köprülenmeye eğilimli) |

| Maddi Form | Öncelikle granüller, pullar, parçalar | Öncelikle ince parçacıklar, mikro peletler, düzensiz şekiller, düz, uzunlamasına öğeler |

| Bireysel Ağırlık | Orta ila büyük veya küçük ama homojen parçacıklar | Çok küçük veya parça sayımı gerektiren yüksek ağırlık değişimine sahip ürünler |

| Paketleme Doğruluğu | Yüksek ağırlık doğruluğu (±0,1g – ± 1g) | 100% sayım doğruluğu (Ağırlık doğruluğu, her bir parçanın tekdüzeliğine bağlıdır) |

| Hız | Çok Yüksek (100-300+ poşet/dakika) | Orta-Yüksek (Ürün boyutuna ve sayım teknolojisine bağlıdır; genellikle tartım cihazlarından daha düşüktür) |

| Uygulamalar | Atıştırmalıklar (patates cipsi/fındık/şekerleme), dondurulmuş gıda, evcil hayvan maması, kahve çekirdekleri, donanım, kimyasal granüller | İlaçlar (tabletler/kapsüller), takviyeler, tohumlar, sakızlı şekerler, elektronik bileşenler, sayıya göre satılan yüksek değerli ürünler |

5. Ürün Seçimini Desteklemek İçin En İyi Uygulama Önerileri

Titiz Malzeme Testleri Yapın: Gerçek malzeme numunelerini test için ruidapacking'e gönderin. Ekipmanın işleme kapasitesini, doğruluğunu, hızını ve belirli ürününüzle ilgili malzeme kaybını bizzat görün.

Gelecekteki Üretim İhtiyaçlarını Planlayın: Gelecekte farklı özelliklere sahip malzemeleri paketlemeniz gerekiyorsa, çeşitli ürünleri işleyebilecek uyumluluğa veya esnekliğe sahip ekipmanlara öncelik verin.

Sorunsuz Üretim Hattı Entegrasyonunu Sağlayın: Seçtiğiniz dozajlama ekipmanının hem yukarı akış besleme sistemleriyle (asansörler, depolama kutuları) hem de aşağı akış paketleme makinesiyle sorunsuz bir şekilde entegre olmasını garantileyin.

Performansı eşleştirin: Darboğazları önlemek için hız ve mekanik/fiziksel arayüzlerdeki uyumluluğu doğrulayın.

Tedarikçi Desteği ve Hizmetine Öncelik Verin: Güçlü teknik uzmanlığa ve hızlı yanıt veren, yüksek kaliteli satış sonrası hizmet ve destek konusunda kanıtlanmış bir geçmişe sahip bir tedarikçi seçin.

Malzemenizin temel özelliklerini dikkatlice değerlendirerek ve çok başlı tartım makinelerinin ve otomatik şişe sayma makinelerinin temel güçlü ve zayıf yönlerini iyice anlayarak, önceden hazırlanmış torba paketleme hattınız için en uygun, verimli ve maliyet açısından etkili dozaj çözümünü güvenle seçebilirsiniz.

Özel gereksinimli bir ilaç makinesine mi ihtiyacınız var?

Deneyimli mühendislerimiz sorununuzu çözebilir!

© 2024 Ruida Paketleme Makineleri Ltd. Şti. Tüm Hakları Saklıdır. | Gizlilik Politikası

Dost Bağlantılar: Zengin Paketleme | Kapsül Dolum Makinesi Üreticileri