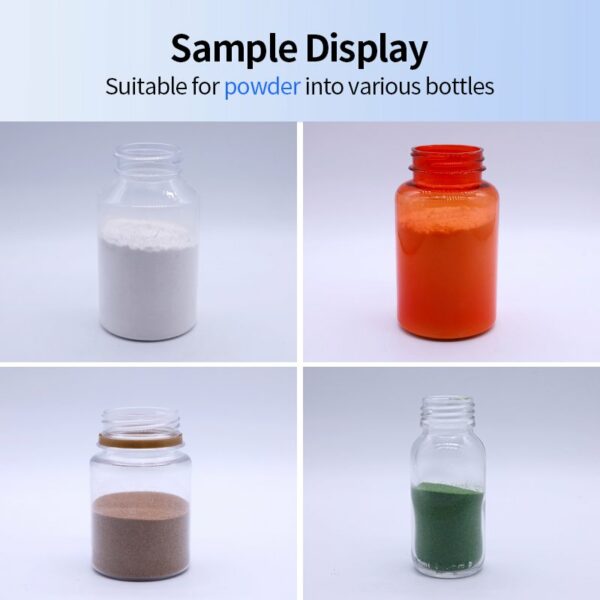

สายการผลิตผงช่วยให้การจ่ายผงแห้งที่ไหลได้ เช่น อาหารเสริมโปรตีน ยาแช่แข็ง เครื่องเทศ และส่วนผสมทางโภชนาการลงในภาชนะต่างๆ เป็นไปอย่างอัตโนมัติ ระบบบูรณาการเหล่านี้มีความจำเป็นสำหรับอุตสาหกรรมที่ต้องใช้ความแม่นยำและถูกสุขอนามัย โดยเฉพาะอุตสาหกรรมยา ผลิตภัณฑ์เสริมอาหาร การแปรรูปอาหาร และสารเคมีพิเศษ ช่วยให้มั่นใจได้ว่าบรรจุภัณฑ์จะสม่ำเสมอและปราศจากการปนเปื้อน

หลักการทำงานของสายการบรรจุขวดผง

จัดเรียงภาชนะเปล่า (ขวด/โถ) ที่ได้รับมาเป็นจำนวนมาก โดยวางให้ตั้งตรงบนสายพานลำเลียง ขนส่งภาชนะตามลำดับผ่านแต่ละสถานีด้วยความเร็วที่สอดประสานกัน

2. เครื่องบรรจุผง

การถ่ายโอนผงสูญญากาศ: ระบบลมจะเคลื่อนย้ายผงจำนวนมากจากที่จัดเก็บไปยังถังสแตนเลสขนาด 50 ลิตรสองใบอย่างนุ่มนวล ซึ่งจะช่วยลดฝุ่นและการแยกตัวให้น้อยที่สุด

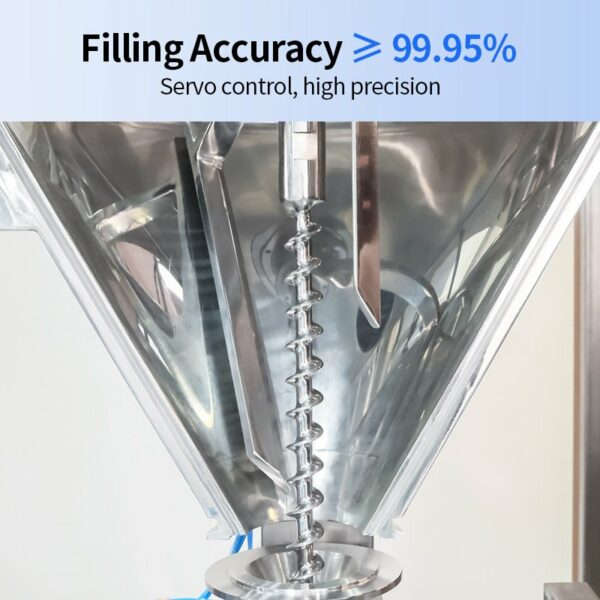

การบรรจุด้วยสว่านขับเคลื่อนด้วยเซอร์โว: ถังบรรจุแต่ละถังจะป้อนผงไปยังสกรูสว่านที่ควบคุมด้วยเซอร์โว มอเตอร์เซอร์โวจะหมุนสว่านเพื่อจ่ายปริมาตร/น้ำหนักที่กำหนดไว้ล่วงหน้าอย่างแม่นยำ ทำให้สามารถกำหนดปริมาณได้อย่างแม่นยำภายใน ±0.5%

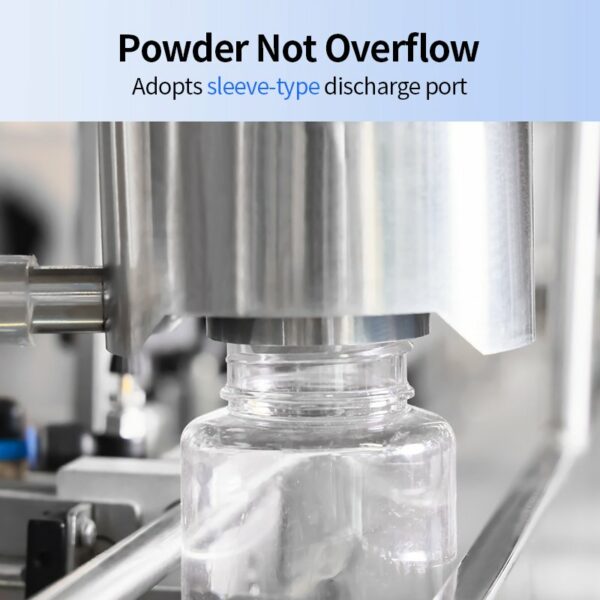

การออกแบบป้องกันการหก: หัวฉีดแบบยืดหดได้ (มีปลอก) จะลดลงมาที่ปากภาชนะระหว่างการบรรจุ พร้อมกันนั้น ตัวเก็บฝุ่นแบบสุญญากาศในตัวจะทำงานเพื่อกักเก็บอนุภาคในอากาศและป้องกันไม่ให้ล้น ซึ่งเป็นสิ่งสำคัญสำหรับผงที่มีความหนาแน่นต่ำ (ฟู) เช่น โปรตีนหรือสารเคมีละเอียด

3. เครื่องตรวจสอบน้ำหนัก

ภาชนะที่บรรจุแต่ละใบจะผ่านเครื่องชั่งน้ำหนักแบบอินไลน์ที่มีความแม่นยำ ตรวจจับความเบี่ยงเบนของน้ำหนักที่เกิน ±0.1% ของน้ำหนักบรรจุเป้าหมาย ดีดภาชนะที่บรรจุน้อยเกินไปหรือมากเกินไปออกโดยอัตโนมัติด้วยแขนลม ภาชนะที่อยู่ในเกณฑ์ความคลาดเคลื่อนจะดำเนินไปได้อย่างราบรื่น

4. เครื่องปิดฝา

ใช้ขันฝาเกลียวหรือฝาปิดให้แน่น หัวจับ (หรือหลายหัวสำหรับสายความเร็วสูง) จะหยิบฝาจากตัวป้อนแบบชาม วางตำแหน่ง และหมุนเพื่อปิดผนึกภาชนะอย่างแน่นหนา หน่วยหัวเดียวเหมาะกับเอาต์พุตที่ต่ำกว่า การกำหนดค่าหลายหัวจะรักษาความเร็วสูง (100 ขวดขึ้นไป/นาที)

5. เครื่องปิดผนึกและติดฉลาก

เครื่องปิดผนึกด้วยฟอยล์เหนี่ยวนำ: สร้างการปิดผนึกด้วยความร้อนแบบกันอากาศเข้าใต้ฝาโดยใช้แผ่นฟอยล์อะลูมิเนียม ช่วยยืดอายุการเก็บรักษาและป้องกันการงัดแงะ

ระบบการติดฉลาก: ใช้ฉลากผลิตภัณฑ์พร้อมข้อมูลชุดการผลิต/วันหมดอายุ ตัวเลือกมีดังนี้:

เครื่องติดฉลากแบบพิมพ์และติดฉลาก: ผสานการพิมพ์บาร์โค้ด/วันที่ลงบนฉลากโดยตรง

เครื่องติดฉลากแบบแขน: สำหรับฉลากหดแบบแขนเต็มตัว

ตัวเลือกเครื่องเข้ารหัส: เครื่องพิมพ์อิงค์เจ็ท/เลเซอร์อินไลน์จะทำเครื่องหมายวันที่/ชุดต่างๆ บนภาชนะโดยตรงหากจำเป็น

สินค้าสำเร็จรูปจะถูกส่งออกโดยใช้สายพานลำเลียงเพื่อการบรรจุหรือวางบนพาเลท

จุดเด่นทางเทคนิค

การควบคุมฝุ่นแบบวงปิด: การถ่ายเทสูญญากาศ + หัวฉีดแบบมีปลอก + ตัวเก็บฝุ่นแบบบูรณาการก่อให้เกิดระบบกักเก็บที่ครอบคลุม

ลำดับชั้นความแม่นยำ: การตวงแบบเกลียว (±0.5%) การตรวจสอบเครื่องตรวจสอบน้ำหนัก (±0.1%) รับประกันการแจกแจงที่เกือบเป็นศูนย์ ขณะเดียวกันยังเป็นไปตามค่าความคลาดเคลื่อนตามกฎระเบียบที่เข้มงวด

ความเข้ากันได้ของวัสดุ: ชิ้นส่วนสัมผัสทั้งหมด (สว่าน, ถัง, หัวฉีด) ใช้สแตนเลส 316L เพื่อความทนทานต่อการกัดกร่อนและเป็นไปตามมาตรฐานด้านสุขอนามัย

สายการผลิตผงอัตโนมัตินี้ให้ความแม่นยำที่เหนือชั้น (การบรรจุ ±0.5%, การชั่งน้ำหนักตรวจสอบ ±0.1%), การควบคุมฝุ่นที่เหนือชั้น และสุขอนามัยที่เป็นไปตาม cGMP การออกแบบแบบแยกส่วนช่วยให้ปรับขนาดได้ตั้งแต่การวิจัยและพัฒนาไปจนถึงการผลิตปริมาณมาก ขณะเดียวกันก็ลดของเสียให้เหลือน้อยที่สุด ทำให้มั่นใจได้ถึงความสมบูรณ์ของผลิตภัณฑ์ที่สม่ำเสมอ และลดต้นทุนแรงงานสำหรับผู้ผลิตยา ผลิตภัณฑ์เสริมอาหาร และอาหาร