120L Automatyczna pionowa maszyna kartonująca

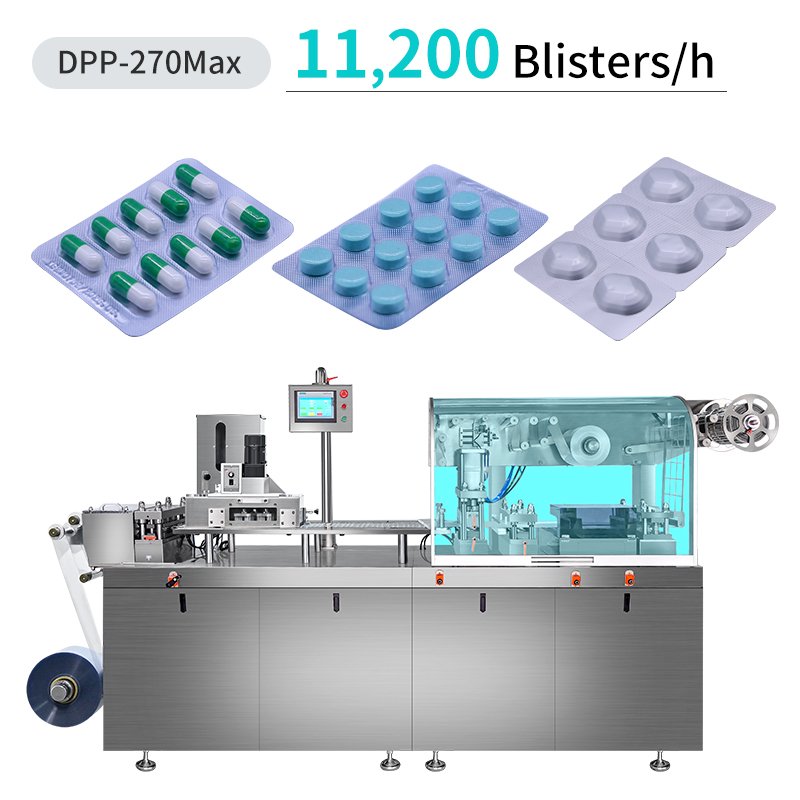

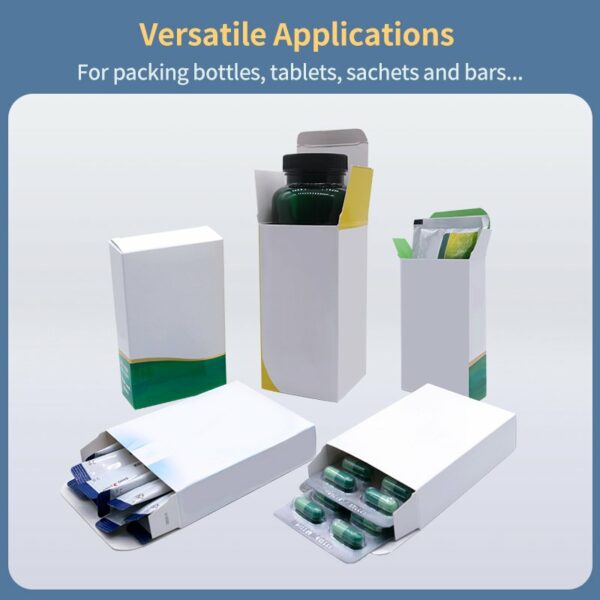

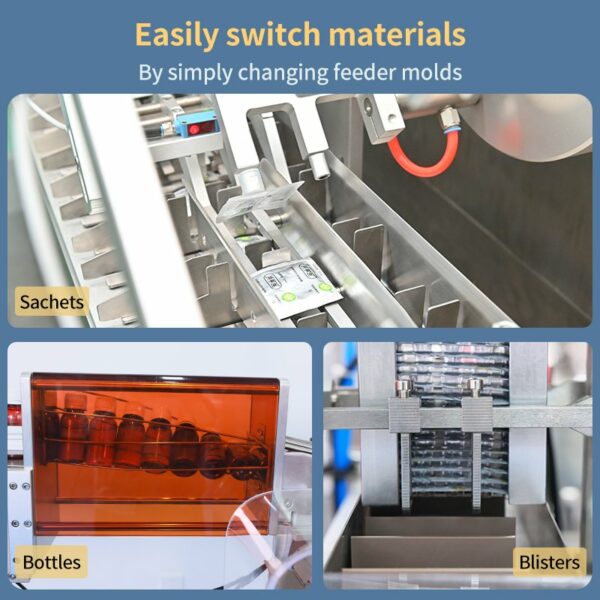

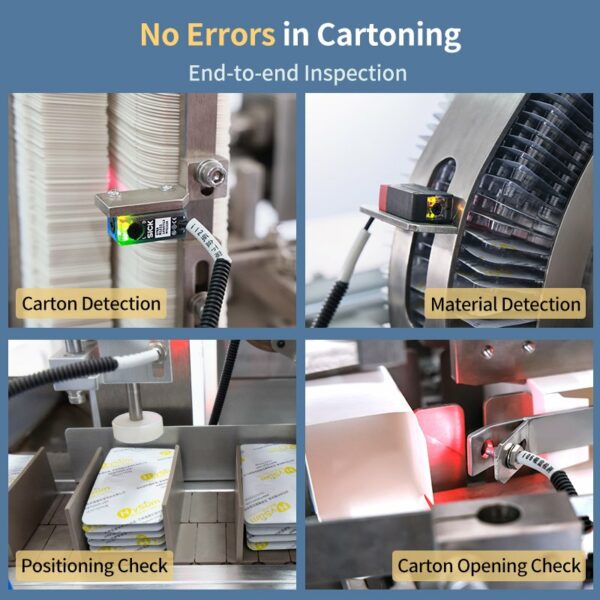

Automatyczna pionowa maszyna kartonująca o pojemności 120 l może pakować blistry, tuby, torebki, paski i inne produkty do kartonów. Zaprojektowana do produktów wkładanych poziomo do kartonu. Kartoniarki są często integrowane z większymi, zautomatyzowanymi liniami pakującymi, wyposażonymi w czujniki i systemy PLC (Programmable Logic Controller), zapewniające precyzyjną obsługę i minimalną ingerencję człowieka.

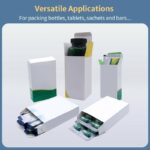

Blistrownice kartonowe można dostosować do obsługi różnych rozmiarów i rodzajów kartonów, oferując wszechstronność w procesach pakowania. Maszyny te znacznie zwiększają prędkość i wydajność pakowania w porównaniu z pakowaniem ręcznym, co czyni je niezbędnymi w środowiskach produkcyjnych o dużej wydajności. Kartoniarki są szeroko stosowane w różnych branżach, w tym: farmaceutycznej, spożywczej i napojów, kosmetycznej…

Podsumowując, maszyna do pakowania tabletek w kartony automatyzuje proces formowania, napełniania i zamykania kartonów, zwiększając tym samym wydajność i gwarantując stałą jakość pakowania.

Specyfikacja:

Do 125 kartonów/min

Nadaje się do talerzy bisterowych, butelek, saszetek itp.

20 dni szybkiej dostawy