When you’re buying packaging equipment for the first time, it’s easy to get pulled into speed specs, shiny options, and price tags. But what usually decides whether your project runs smoothly (or drifts into delays, rework, and downtime) is the pharmaceutical packaging machinery manufacturer behind the machine: how they define scope, prove performance, deliver documentation, and support you after installation.

You just need a simple way to choose well:

- lock your scope, 2) ask the right questions early, and 3) demand proof in a buyer-friendly way.

Pharmaceutical packaging machinery manufacturer: set your scope

Here’s the fastest way to set scope so suppliers can’t hide behind vague quotes—and so you don’t overbuy.

Step 1: Name the product and its “handling risk”

Write this in plain words:

- Product form: tablets, capsules, powder, liquid

- Fragile or messy? (dusty powder, sticky liquid, friable tablets, static-prone parts)

- Any special constraints: moisture sensitivity, light sensitivity (if relevant)

Why it matters: the same “packaging line” behaves very differently when the product is dusty, brittle, or easy to spill. A serious supplier will ask these questions before talking about speed.

Step 2: Pick the packaging route

Choose your route using the simplest chain:

- Primary pack: maszyna do pakowania w blistry Lub tablet capsule counting machine

- Secondary pack: maszyna do pakowania w kartony (if you carton)

- Line add-ons (only if needed): maszyna do etykietowania, vision inspection system, checkweigher, serialization/track & trace

You’re not locking models yet—just the route. That’s enough to filter out suppliers who aren’t a fit.

Step 3: Set one realistic output target

Give one number the supplier can design around:

- Target output per minute (or per hour)

- Shifts per day (1 / 2 / 3)

- Preferred staffing level (for example: “we want one operator to run it”)

If you don’t know your exact number, give a range (e.g., “60–90 bottles/min”). What you’re avoiding is “high speed” with no definition.

Step 4: List your site limits in one line

Keep it simple:

- Space (approximate footprint limit), ceiling height if tight

- Power/air availability (even “standard plant utilities” is fine as a starting note)

- Any must-have integration (printer, coder, existing conveyor, ERP/serialization)

Step 5: Turn it into a one-paragraph requirement

This is the single most useful thing you can send to every supplier so you get clean, comparable replies:

One-paragraph scope (copy/paste template):

We pack [product: tablets/capsules/etc.] into [blister packs / bottles / cartons] with a target of [X units/min or range] on [1–2 shifts/day]. The line should include [primary pack], plus [cartoning/labeling/inspection as needed]. Product handling needs attention to [dust/breakage/spillage/moisture]. Site limits: [space/utility notes]. We want a quote that clearly states what’s included (installation/training/spares/documentation) and what’s optional.

If a supplier can’t respond clearly to that paragraph—especially on what’s included and what’s optional—move on. It’s one of the simplest early signs you’re not dealing with a dependable pharmaceutical packaging machinery manufacturer.

Write a one-paragraph requirement

You already have the scope paragraph. Now make it “quote-ready” by requesting a structured reply from every supplier. This keeps the conversation from turning into sales talk.

Ask each supplier to reply with the same five blocks:

- Proposed configuration (machines/modules included)

- Included vs optional (installation, training, spares kit, tooling, documentation)

- Utilities and footprint (power/air, layout assumptions)

- Throughput basis (what product, what pack, what conditions)

- Acceptance basis (what will be tested, what evidence you receive)

This isn’t “being difficult.” It’s how you make quotes comparable without needing deep technical knowledge.

Shortlist 6–8 manufacturers fast

For a first-time buyer, the goal is speed and clarity: you want a short list of suppliers who communicate well and can prove what they claim.

A simple shortlist flow

- Start with 6–8 suppliers that claim your packaging route.

- Keep the ones that ask sharp questions about your product and packaging path.

- Remove the ones that only talk about “top speed” and never define conditions.

Quick filters that work

A supplier is usually a poor fit if they:

- refuse to explain what’s included vs optional

- dodge questions about documentation, training, or spare parts

- won’t discuss testing with your sample or a realistic substitute

- keep changing the scope to make the quote look cheaper

By the end of this step, you should have 2–3 finalists that feel straightforward to work with. That matters more than most buyers think—because miscommunication is a hidden cost.

Ask these 10 questions first

These questions are designed so a beginner can get meaningful answers without chasing jargon. You’re looking for clear, specific answers and a willingness to show evidence.

- What is included in the quoted scope—exactly?

Ask for a line-item list of what you get, plus what is optional. - Have you built this same packaging route before?

“Similar product + similar pack format + similar speed target” is the key. - What’s the real output basis?

What product, what pack, what operator level, and what reject rules? - How long is changeover, and what changes during changeover?

The best answers mention tooling, recipe settings, and what an operator must adjust. - How do you detect and reject defects?

You don’t need a lecture—just what defects are covered and how rejects are handled. - What documentation do you deliver with the machine?

Manuals, drawings, spare parts list, basic test records—ask for a sample set. - How do you prove performance before shipment?

You’re listening for a clear test plan and what evidence you’ll receive. - Who installs and trains, and what’s included?

Ask what training materials you get and how many days are included. - What spare parts do you recommend for year one?

Good suppliers have a simple recommended spares list and lead-time clarity. - What does after-sales support look like in week 1 and month 6?

You want response time, escalation path, and what’s remote vs on-site.

If you get vague answers to half of these, you’re not making a “right choice,” you’re taking a gamble—especially when choosing a pharmaceutical packaging machinery manufacturer for the first time.

Get proof with a simple test plan

You don’t need a complex validation program to protect yourself. You need a basic plan that answers one question:

Can this supplier prove the machine will run your product and packaging route reliably?

What “proof” looks like (beginner-friendly)

Ask for three things:

- A short run that shows stability, not just a fast burst

- A defect/reject demonstration, even if simplified (missing product, print check, seal check—whatever applies)

- A basic evidence pack: test notes, settings summary, and results you can keep

FAT and SAT in plain language

- FAT (Factory Acceptance Test): proof before the machine ships.

- SAT (Site Acceptance Test): proof after it’s installed in your facility.

If you’re buying one machine, FAT/SAT can be simple. The point is not paperwork—it’s making sure you’re not paying for surprises.

Score suppliers on one page

When you’re new, it’s easy to choose based on who sounds confident. A scorecard forces you to choose based on what you can verify.

Table: One-page manufacturer scorecard (fill in as you go)

| Check item | What to ask | What “good” looks like | Score (1–5) |

| Scope match | Have you built this route before? | Relevant examples + clear boundaries | |

| Quote clarity | What’s included vs optional? | Written list + no scope shifting | |

| Output basis | Under what conditions is output rated? | Product/pack/operator assumptions defined | |

| Changeover | What changes during changeover? | Practical steps + realistic time | |

| Quality & rejects | How are defects detected/rejected? | Simple explanation + demo readiness | |

| Dokumentacja | What docs come with delivery? | Sample docs + clear deliverable list | |

| Test proof | What does FAT include? | Test plan + evidence pack | |

| Install & training | Who installs/trains and what’s included? | Named plan + training materials | |

| Spares & service | What spares/SLA do you recommend? | Recommended spares + response time | |

| Delivery & support | Lead time + long-term support | Realistic schedule + support pathway |

Use this to rank suppliers. Then sanity-check the ranking with your own reality: communication quality, speed of answers, and whether they treat your requirements consistently.

Lock service, spares, and acceptance terms

This is where first-time buyers get burned—not because the supplier is “bad,” but because the agreement is fuzzy.

What to lock in writing

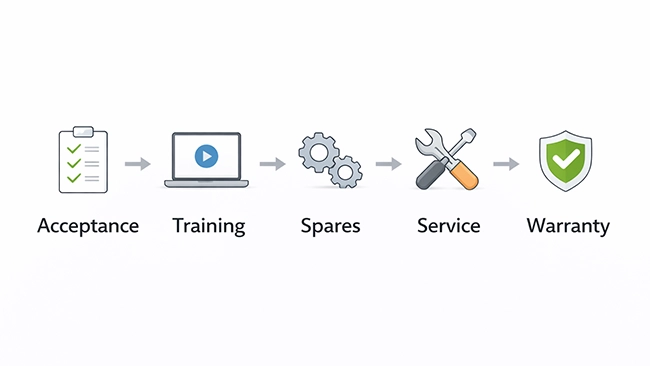

- Acceptance: what will be tested, what counts as pass/fail, and what evidence is delivered

- Training: number of days, training language, and training materials provided

- Spares: recommended spares list + lead times + what’s considered a wearing part

- Service response: response time targets and escalation path

- Warranty: when it starts, what it covers, and what voids it

- Boundaries: what you must provide (utilities, operators, consumables, pack materials)

A helpful rule: if it affects schedule, uptime, or cost, it belongs in writing.

If you’re building a shortlist, Pakowanie ruidy can be one option to include—especially if you value clear documentation, a sizeable in-house R&D team, and a supplier with established quality systems (ISO certifications) and global customer experience. Their support model also emphasizes structured commissioning/training and responsive after-sales coordination, which matters when you’re buying.

Wniosek

To make the right choice, don’t start with model numbers. Start with scope, ask the ten questions, and insist on basic proof you can keep. When you choose a pharmaceutical packaging machinery manufacturer this way, you reduce surprises in delivery, installation, and ramp-up—and you give your team a much cleaner path to stable production.

Często zadawane pytania

1) What should I send to a manufacturer if I’m buying for the first time?

Send a one-paragraph scope: product form, packaging route, output target, site limits, and what you expect in delivery (training, spares, docs).

2) How many manufacturers should I shortlist before deciding?

Start with 6–8, narrow to 2–3 finalists based on clarity, scope fit, and proof.

3) Do I need FAT/SAT if I’m only buying one machine?

Yes, but keep it simple: define what will be tested and what evidence you’ll receive. That alone prevents many disputes.

4) What documents should I ask for to stay GMP-ready later?

At minimum: manuals, drawings, spare parts list, basic test records, and any compliance-related documents your site typically keeps.

5) How can I judge after-sales service before paying a deposit?

Ask for response-time commitments, escalation steps, recommended spares, and a clear line on what is remote vs on-site.

6) Turnkey line or start with one machine—which is safer?

If you’re new, starting with one machine can reduce risk—unless your packaging route requires tight line integration from day one.

7) Why do quotes vary so much for “similar” packaging machines?

Usually because scope differs: what’s included, how acceptance is defined, what documentation is delivered, and what service/spares are bundled.

8) What warranty and spare parts terms are reasonable?

A clear warranty start point, clear exclusions, and a recommended year-one spares list with lead times are the essentials.

Referencje

FDA — Process Validation: General Principles and Practices

https://www.fda.gov/media/71021/download

EU GMP — Annex 15: Qualification and Validation

https://health.ec.europa.eu/system/files/2016-11/annex15_01-2015_en_0.pdf