- Thuis

- Zakjesverpakkingsmachine

Zakjesverpakkingsmachine

Sachet packing machine specialize in high-speed production of ultra-narrow, elongated sachets for precise single-dose applications. They excel at packaging free-flowing powders, granules, and fine solids into compact, portable formats. Dominant applications include the pharmaceutical & nutraceutical sectors (OTC powders, supplements, electrolytes), food & beverage industry (instant coffee, sugar, drink mixes, spices, protein powders), cosmetics (sample-sized serums, bath salts), and industrial chemicals (detergent samples, additives).

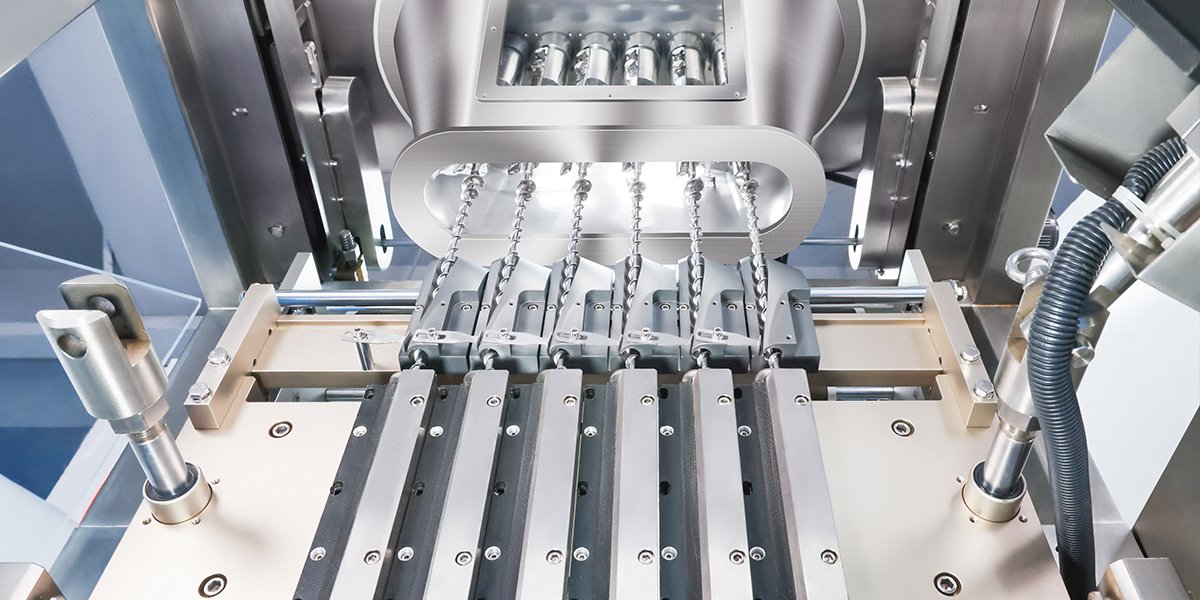

Stick packaging machine perform vertical-form-fill-seal (VFFS) operations from roll film, creating tamper-evident seals with precision dosing. Key features include multi-lane configurations for ultra-high outputs (400+ packs/min), and compatibility with multi-layer barrier films. Ideal for promotional samples, travel-sized products, and portion-controlled goods, stick pack machines deliver cost-effective material usage, enhanced shelf presence, and consumer convenience while minimizing waste.

Sollicitatie:

Stick packing machine can pack powder, granule and liquid into 3 side sealed, 4 side sealed, back sealed sachets.

Werkingsprincipe

Vertical form fill seal machine(VFFS Machine) automatically form, fill, and seal pre-cut or roll-fed film into individual pouches by precisely measuring product (powder/liquid/granules) into a shaped film tube, then heat-sealing and cutting it into finished sachets.

Features Advantages

Ruidapacking streeft ernaar machines te produceren met superieure kwaliteit die voldoen aan de GMP-normen en die tegelijkertijd efficiënte en praktische functies bieden.

Feeding High Accuracy

Adopt 6 servo motors control long screw feeder, high precision, filling error ± 0.1mg.

Modulair ontwerp

Allows for quick replacement of screw/piston filling heads to accommodate both solid and liquid products.

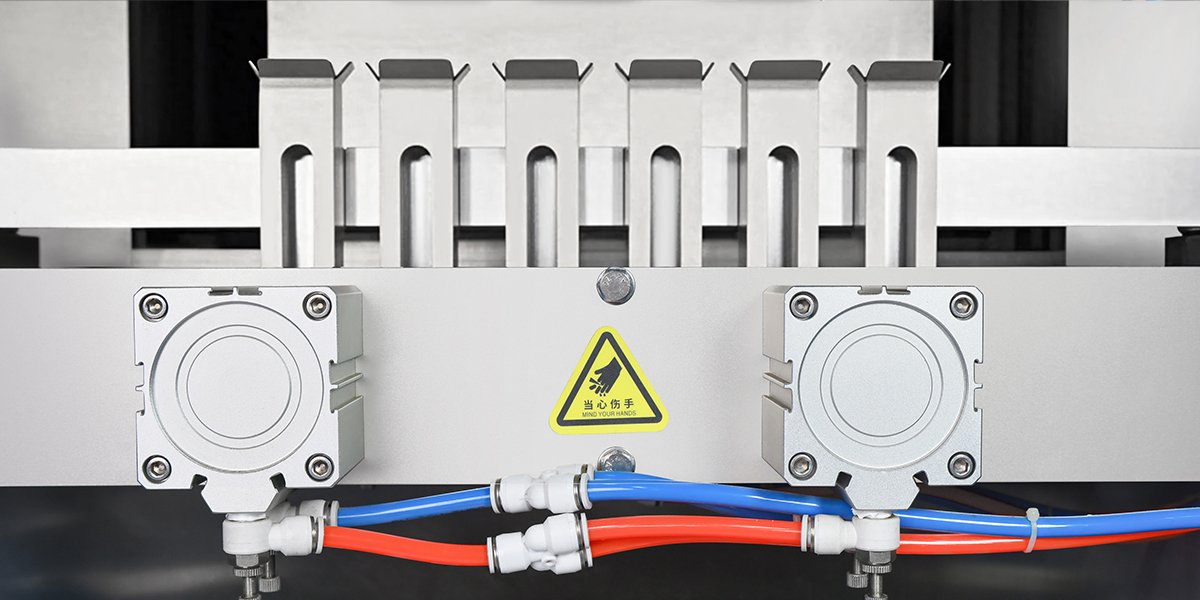

Strong Sealing Performance

Vertical sealing, horizontal sealing, back sealing, high temperature sealing effect, no air leakage.

Technische parameters

According to your output choose suitable machine.

| Model Name | RD-SPM 480 6 lanes powder sachet packing machine |

| Maximale filmbreedte | 480 mm |

| Productiecapaciteit | 240 Bags/min |

| Control Style | Adopt Siemens PLC controlling system |

| Spanning | AC380v 3 phases 50Hz(customized) |

Ondersteunende producten

NJP-3800D Automatische capsule-vulmachine

NJP-3800D automatic capsule filling machine works by automatically feeding empty capsules, filling them with powder, closing, and output for packaging. ...

Fabrikant van blisterverpakkingsmachines

Blister packing machine manufacturer offer various type machines that boosts output while lowering labor costs and material waste.

Fortune 500 kwaliteitsleverancier

Customers Say We're Good

Get praise from SINOPHARMA, GSK, USPharma, Atlantic Grupa, Robinson Pharma…

6S-beheer

We check every process to ensure machines meet CE, cGMP, ROHS, FDA…

Mould Can Be Customized

Available in different sizes and dimensions of capsules and tablets to suit your needs

Collaborative Projects

You only need to provide the blisters size, and our engineers will take care of the rest.

On-site Debugging Worldwide

Global customer service center in the United States is on standby. You should responsible for engineers’ round-trip air tickets, accommodation and meals + $350/hour

Veelgestelde vragen

Feeling overwhelmed by the vast array of sachet packing machines? You’re not alone. Many first-time buyers find the process daunting, fearing costly mistakes or being misled. The key to success lies in focusing on two critical factors: what you’re packing and your production needs. This guide cuts through the complexity.

1. What Materials Are You Filling?

This is the single most crucial decision point. The nature of your product determines the optimal filling mechanism for accuracy, speed, and product integrity:

Powders (Spices, Milk Powder, Pharma, Detergents)

Best Choice: Servo-Driven Auger Filler

Why? Unmatched precision is essential. Servo motors provide exceptional control over the auger screw, enabling incredibly accurate dosing. Look for systems boasting accuracies within ±0.1% or better (±0.1mg for pharmaceuticals). This minimizes waste and ensures consistent product weight in every sachet. Avoid vibratory or basic auger systems if high precision is non-negotiable.

Granules(Sugar, Pellets)

Best Choice: Volumetric Cup Filler

Why? Gentleness is paramount. Cup fillers scoop a precise volume of product without crushing or damaging delicate granules. They are generally faster than augers for free-flowing granules and offer good accuracy (±1-2% typically). Ensure the cup size matches your desired fill weight range.

Liquids (Sauces, Oils, Cosmetics)

The Choice Depends on Viscosity & Precision:

Low Viscosity (Water-like, Juices): Piston Pumps or Peristaltic Pumps (Metering Pumps). Piston pumps offer good speed and reasonable accuracy (±1-2%). Peristaltic pumps are simple, handle shear-sensitive products well, and avoid contamination (product only touches the tube), but generally have lower accuracy (±2-3% or more) than piston pumps.

Medium to High Viscosity (Honey, Paste, Ketchup, Shampoo): Piston Pumps are the standard workhorse. They provide positive displacement, forcing thick liquids reliably. Accuracy is typically ±1-2%.

High Precision Required (Pharma, Premium Cosmetics, Expensive Liquids): Ceramic Piston Pumps. These offer exceptional accuracy (±0.5% or better) and durability for demanding applications, even with various viscosities. They are an investment but crucial where precision is paramount.

2. Defining Your Sachet & Production Needs (Size and Speed)

Once you know the how (filling system), determine the what (sachet) and how many (output):

Sachet Size (Width & Length)

Machine Size: Sachet packing machines are fundamentally sized by the maximum bag width they can handle. Know the dimensions of your finished sachet. Don’t just consider the product volume; account for the material thickness and desired seam/seal width. Choosing a machine too small for your largest planned sachet is a major limitation. Conversely, a vastly oversized machine can be inefficient and costly.

Sealing method: Find out whether your product is three-side sealed, four-side sealed or back sealed. If you can’t tell the specific sealing method, you can directly send us the product picture so that we can better identify it.

Film Type: Specify the material (laminated foil, PET/PE) as it affects sealing parameters and film handling.

Production Output (Speed – Sachets Per Minute – SPM)

Be Realistic: Calculate your required average and peak production rates (sachets per minute – SPM). Don’t just go for the fastest machine advertised; consider your actual daily/weekly volume, changeover times, and potential growth. Overspending on excessive speed you don’t need is inefficient.

Machine Capability: Clearly communicate your output requirements to suppliers. A machine designed for 60 SPM will be vastly different (and less expensive) than one rated for 200 SPM. Ensure the machine can consistently achieve your target speed with your chosen sachet size and product.

Automation Level: Higher speeds often necessitate more automation (auto film loading, auto date coding, sachet cartoning machine, integrated checkweighers, robotic case packing) to maintain efficiency and reduce labor costs. Factor this into your budget and planning.

3. Putting It All Together

Before talking to suppliers, arm yourself with this essential information:

3.1. Product Type: Powder, Granule, Liquid? (Specify if abrasive, sticky, fragile, etc.)

3.2. Liquid Viscosity: (If applicable – Thin, Medium, Thick?)

3.3. Required Filling Accuracy: (±0.5%, ±1%, ±0.1g – Be specific!)

3.4. Finished Sachet Dimensions: Max Width? Max Length? Min Width/Length?

3.5. Desired Sachet Style: (3-side seal, 4-side seal, back seal)

3.6. Packaging Material: (Laminated Alu Foil, PET/PE, Paper Composites)

3.7. Target Production Speed: (Sachets Per Minute – Average & Peak)

3.8. Available Factory Space & Utilities: (Power requirements, compressed air, space footprint)

Choosing wisely starts with knowing YOUR needs. By meticulously defining your product and production parameters, you transform from a vulnerable novice into an informed buyer. You’ll ask the right questions, understand supplier proposals clearly, and confidently select the sachet packing machine that delivers consistent quality, efficiency, and a strong return on investment. Don’t settle for generic solutions; demand the machine engineered for your specific success.

Heeft u een farmaceutische machine nodig? Met speciale behoeften?

Onze ervaren technici lossen uw probleem op!

Oplossingen

Neem contact met ons op

© 2024 Ruida Packing Machinery Co., Ltd. Alle rechten voorbehouden. | Privacybeleid

Vriendelijke links: Rijke verpakking | Fabrikanten van capsule-vulmachines