Capsule Bottellijn

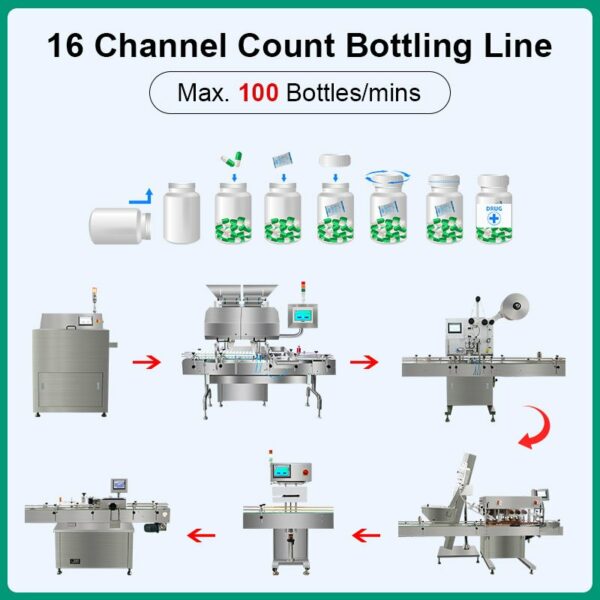

Capsule bottellijn componenten :

Flesontwarmer: Flessen worden automatisch in de lijn gevoerd met behulp van een transportband of draaiplateau.

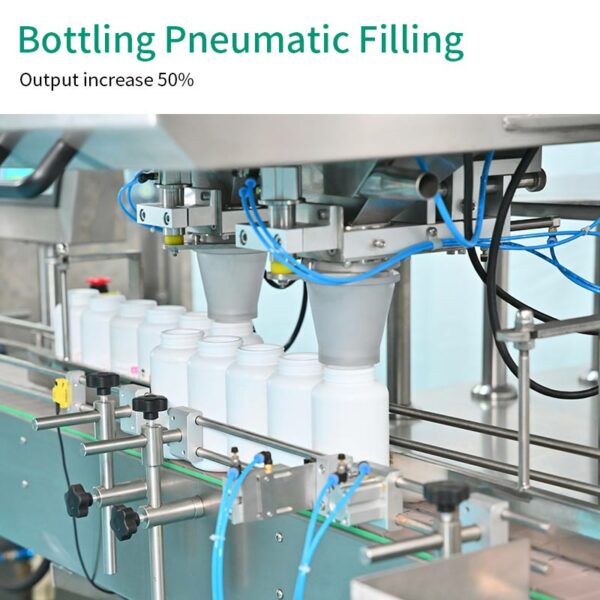

Telmachine: Capsules worden in flessen gevuld na het tellen.

Desiccant-invoeger: Voegt desiccantpakketten in de flessen om de stabiliteit van de capsules te behouden en vochtbeschadiging te voorkomen.

Dopmachine: Dekt automatisch de gevulde flessen af om ze te verzegelen.

Inductiezegelmachine: Verzegelt de fles met een folie-laag om te zorgen voor bewijs van ongeoorloofd openen en de versheid van het product te behouden.

Etiketteermachine: Brengt etiketten aan op de flessen met productinformatie, batchnummers, vervaldatums en barcodes.

Specificatie:

Tot 100 flessen/minuut

nauwkeurigheidspercentage > 99.98%

Geschikt voor capsules/tabletten/gummyberen van 3-40 mm…