DDP 평판 블리스터 포장기

DDP Flat Plate Blister Packing Machine is designed for packaging tablets, capsules, and other solid-dose pharmaceutical products. The machine operates based on a combination of heat, pressure, and mechanical movement to form, fill, and seal the blister packs.

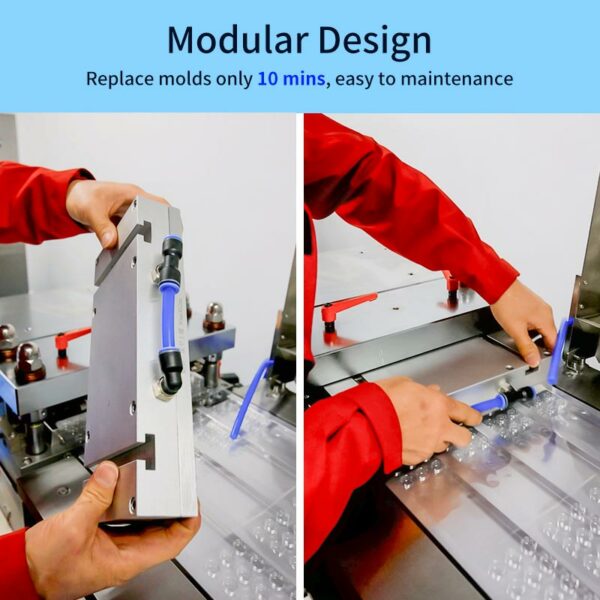

Forming Process: The heated film is drawn into a set of molds by a vacuum action, forming blisters. The molds determine the shape and depth of the blisters.

Filling: After the blister are formed, the products (tablets, capsules, etc.) are placed into the formed pockets.

Sealing: The formed and filled blister is then passed through a sealing station, where heat and pressure are applied to bond the lidding film to the plastic film.

Punching & Cutting: After sealing, the machine may punch out individual blisters or cut the continuous strip of blisters into individual packs.

사양:

최대 11,200개/시간

정제, 캡슐, 전자담배에 적용 가능

PVC, PS, PET 소재에 적합