Choosing the right capsule filling machine is a crucial decision for optimizing production efficiency, ensuring accurate dosage, and maintaining regulatory compliance in pharmaceutical, nutraceutical, and supplement manufacturing. The right machine can help you scale production, reduce costs, and improve product consistency, while a poor choice can lead to low operational efficiency, increased downtime, and poor-quality products.

In this ultimate buyer’s guide, we will provide a detailed overview of the various types of capsule filling machines, their key features, and specifications. This guide will equip you with the knowledge needed to confidently choose the best capsule encapsulation machine for your business needs, based on factors such as speed, accuracy, versatility, and compliance.

What Is a Capsule Filling Machine?

A 캡슐 충전기 automates the process of filling empty hard capsules with a variety of materials, including powders, granules, liquids, or pellets. These machines eliminate the manual labor involved in filling capsules, dramatically improving speed, consistency, and accuracy in production.

In addition to improving production efficiency, capsule dosing machines help ensure that manufacturers meet stringent Good Manufacturing Practices (cGMP) and FDA regulations, ensuring the consistency and quality of every batch produced. Whether you are producing pharmaceutical drugs, dietary supplements, or nutraceuticals, these machines are indispensable for high-volume manufacturing.

The extensive use of capsule filling equipment is a feature of industries characterized by stringent hygiene and precision standards. The ability of this machine to automate the filling process has made them an essential part of modern manufacturing, reducing human error and enhancing product consistency.

캡슐 충전기의 종류

Selecting an appropriate capsule machine begins with a clear understanding of the market’s primary offerings. These generally fall into three categories: manual, semi-automatic, and fully automatic models. The optimal choice for your operation is ultimately determined by factors such as production scale, desired throughput, and budget constraints.

The following breakdown details the applications and key benefits of each machine type.

Manual Capsule Fillers

Manual capsule fillers are hand-operated machines that do not require electricity. The manual filling process involves two key steps. First, the operator places empty capsules into designated trays. Then, using hand-operated tools such as tampers and levers, they complete the filling and sealing of the capsules.

◼ Best for: Small batches, lab-scale production, research and development (R&D), clinical trials, and startups.

◼ 산출: Range from tens to a few hundred capsules per hour—a comparatively low output.

◼ 장점:

- Low cost and simple operation

- Compact design, suitable for small spaces

- Great for flexibility, ideal for small batches and experimental formulations

제한 사항:

- Slow and labor-intensive

- Not suitable for large-scale production

- High potential for human error and inconsistencies in fill weight

Manual fillers are most commonly used by individuals at home. For small-scale production or custom formulations, they provide flexibility but come with limitations in speed and consistency.

Semi-Automatic Capsule Fillers

This kind of machine integrates motorized parts with manual handling steps. The operator loads empty capsules into a hopper, and the machine then automatically orients, separates, fills, and locks the capsules. However, the operator is still required to replenish the capsules and powder during operation.

◼ Best for: Small to medium-scale production where full automation isn’t necessary.

◼ 산출: Throughput is typically measured in tens of thousands of capsules per hour, though the exact figure varies by machine model.

◼ 장점:

- Increased throughput compared to manual machines

- More automated functions like capsule orientation, filling and locking

- Affordable, offering a good balance between automation and manual control

제한 사항:

- Still requires operator involvement for loading and replenishing materials

- Higher labor requirements compared to fully automatic machines

Semi-automatic capsule filler machines are ideal for labs and small to medium-sized businesses that have limited capital investment but need better productivity than manual machines. These machines offer greater flexibility and are easier to operate than fully manual models, making them a popular choice in the pharmaceutical and nutraceutical industries.

Fully Automatic Capsule Fillers

Fully automatic capsule filling machines are designed for production with minimal human intervention. These machines automatically load empty capsules, separate the capsule bodies and caps, meter precise doses of active ingredients into the bodies, recombine the caps with the bodies, and eject the finished capsules.

◼ Best for: Pharmaceutical and nutraceutical manufacturing, where operational requirements mandate both high-volume output and a high degree of automation.

◼ 산출: Can reach several hundred thousand capsules per hour—a capacity that is heavily contingent upon the number of stations and the specific machine model.

◼ 장점:

- High speed—optimized for large-scale production

- Precise dosing control, ensuring product consistency

- Drastic cuts in labor expenses and the minimization of errors attributable to human factors.

- Best suited for continuous production lines

◼ 제한 사항:

- Higher initial investment cost

- Complex setup and maintenance may require specialized technicians

- Requires significant floor space and higher operational costs

The primary target users for fully automatic hard capsule filling machines are large-scale pharmaceutical firms and contract manufacturing organizations (CMOs) who demand both high throughput and product consistency. These machines integrate seamlessly with other production systems, such as blister machine or bottle filling line, and offer real-time monitoring and control to maintain optimal performance.

Specialized Capsule Filling 디evices

In addition to standard capsule fillers, there are specialized machines designed for handling specific types of filling material, such as liquids or soft gels.

Liquid Capsule Fillers: These machines are designed specifically for filling capsules with liquids or suspensions, such as oils or medicinal liquid formulations. Liquid fillers often require precision pumps and temperature controls to manage viscosity.

Softgel Encapsulation Machines: These machines are used to fill soft capsules with liquid or semi-solid substances, often used in vitamin or nutrient supplements. Softgel encapsulators operate differently from traditional capsule fillers but serve a related purpose in encapsulating liquid-filled products.

These specialized machines are ideal for manufacturers producing liquid-filled products or softgel capsules. Liquid fillers, for example, can handle high-viscosity formulations, while softgel encapsulators are specifically designed to handle capsules.

Before diving into key features of a encapsulation machine, it helps to compare machine types side by side. The table below summarizes typical throughput, accuracy ranges, and changeover expectations so you can quickly narrow down which category fits your production reality (not just a brochure speed).

| 기계 유형 | Typical Output (capsules/hour) | Practical Fill Weight Control (typical) | Changeover Time (typical) | Operators | Best Fit (most common use) | Budget Level |

| 수동 캡슐 필러 | 100–1,000 | Operator-dependent; often ±5–10% | 10–30 min | 1 | R&D, trials, micro-batches, test marketing | 낮은 |

| 반자동 캡슐 충전기 | 10,000–20,000 | Often ±3–5% (material-dependent) | 30–90 min | 1-2 | Small manufacturers, growing supplement brands, flexible SKUs | 중간 |

| 전자동 캡슐 충전기 | 20,000–200,000+ | Often ±1–3% (with stable powder flow) | 60–180 min | 1 | Pharma/CMO, continuous production, stricter QA & documentation | 높은 |

| Liquid Encapsulator Machine (specialty) | 5,000–60,000 | Volume-driven; depends on viscosity & pump stability | 60–180 min | 1 | Oils, suspensions, liquid actives in hard capsules | Medium–High |

| Softgel Encapsulation Line (specialty) | Line-specific | Process-driven; shell + fill control | Longer & validated | 2+ | Softgels for oils/vitamins; dedicated product lines | 높은 |

Key Features to Consider Before Purchasing a Capsule Filling Machine

When buying a capsule making machine, there are several key features that determine its performance, quality, and suitability for your production needs. Several critical factors must be examined prior to purchasing a capsule machine.

Construction & Durability

The machine’s construction and materials are critical for achieving long-term, reliable operation. Capsule fillers made from high-quality stainless steel (preferably SUS304 or SUS316) are most commonly used because they are durable, resistant to corrosion, and easy to clean. A solid frame minimizes wear and tear over time, and ensures that the machine can perform consistently, even under high-speed conditions.

에서 Ruidapacking, we ensure that our machines, such as the capsule fillers, are built with FDA-compliant stainless steel, ensuring they meet the highest standards of quality and durability.

Capacity & Speed

As a key performance parameter, the machine’s capacity is measured by the maximum number of capsules it can fill per hour. The speed should align with your production volume. Machines range from small-scale units that fill hundreds of capsules per hour to high-speed rotary systems that can process over 100,000 capsules per hour.

Capacity is important: It is advisable to select a machine that accounts for both your immediate production needs and has the capability to accommodate future growth.

Accuracy & Precision

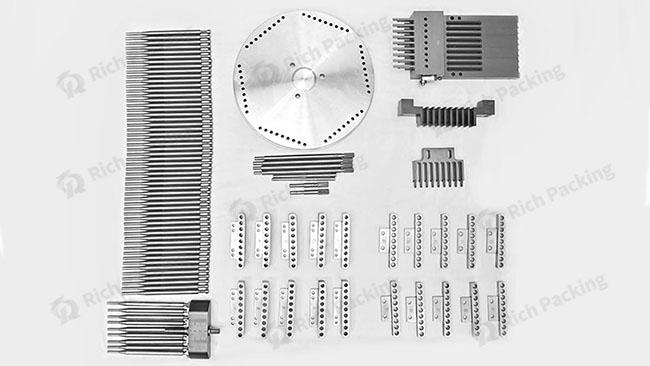

Dosing accuracy is one of a key performance metric for any capsule filling equipment. Machines that use precision auger fillers, tamping pins, 또는 dosing discs ensure that the correct amount of powder or liquid is dispensed into each capsule.

Versatility & Flexibility

It’s important to choose a machine that offers versatility in handling different capsule sizes (from #000 to #5) and different fill materials (powders, granules, liquids). Look for machines that allow quick changeovers for different capsule sizes, formulations, or even product types.

Ease of Use & Controls

A well-designed, user-friendly interface results in straightforward and efficient machine operation. Modern machines come equipped with touchscreen HMIs (Human-Machine Interfaces), which allow for easy adjustments and real-time monitoring. These systems should enable operators to adjust speed, fill weight, and other parameters with ease.

Three Steps To Select The Appropriate Capsule Filling Machine For Your Production

Step 1: Assess Your Production Needs

Assessing your current and projected throughput requirements, along with the specific types of capsules to be processed. If you’re unsure, estimate how many capsules you need to produce each day and the number of batches you plan to run. Also, consider your future growth; a machine with scalability options will save you from having to upgrade too soon.

Step 2: Match Machine Features to Your Needs

Make sure the machine’s speed, accuracy, and versatility match your specific needs. Consider the types of products you plan to fill (powders, liquids, soft gels) and the capsule sizes you need to process. Additionally, check the maintenance and cleaning requirements of the machine.

Step 3: Evaluate Vendor Reputation and Support

The supplier’s market reputation and quality of after-sales support are critical non-technical considerations that cannot be overlooked for long-term project success. A reliable supplier should provide services such as installation, 훈련, 그리고 유지 to ensure the machine performs optimally for years.

Capsule Filling Machine Common Problems and How to Avoid Them

Problem 1: Filling Weight Variation

Filling weight variation can occur when the machine’s dosing system isn’t accurate enough or if powder flow isn’t consistent. Look for machines with adjustable dosing systems and in-process checks that can detect and correct underfills or overfills.

Problem 2: Capsule Jamming

Capsule jamming happens when the capsules are not properly oriented or when the machine’s feeding mechanism isn’t working correctly. Regular machine maintenance and proper setup can prevent this issue.

Problem 3: 가루 Leakage Issues

Leaking capsules are often caused by inadequate sealing. Ensure that the machine has a reliable capsule-locking mechanism and includes features that detect leaks during the powder filling process.

Conclusion: Making an Informed Purchase Decision

Selecting the right capsule filling machine depends on assessing your production needs, machine capabilities, and vendor support. Whether you need a manual, semi-automatic, or fully automatic machine, choosing the right model will ensure that your production line runs efficiently, accurately, and with minimal downtime.

FAQ – Frequently Asked Questions About Capsule Filler

1. How accurate are capsule machines in dosage variation?

High-quality capsule machines can achieve ±1–3% variation in fill weight. This is typically the industry standard for most machines. Precision dosing systems such as auger fillers, tamping pins, 그리고 dosing discs are often used to maintain tight weight control.

2. How 에 maintain and clean a capsule making machine?

Adherence to established maintenance and cleaning protocols is critical for sustaining peak equipment performance and eliminating contamination risks. Some practices include:

◼ Regular Cleaning: It is a core quality standard to clean the machine after each batch, thereby eliminating any risk of cross-contact and ensuring product purity. This involves disassembling parts such as the molds and filling stations.

◼ 매끄럽게 하기: Moving parts, such as the auger and tamping pins, should be regularly lubricated to ensure smooth operation.

◼ Wear Parts Replacement: Parts like seals, gaskets, and tamping pins should be inspected regularly and replaced when necessary to avoid performance issues.

◼ Validated Cleaning: For pharmaceutical applications, validated cleaning methods (CIP/SIP) should be implemented, particularly if the machine handles different formulations or potent compounds.

Some machines are designed for easy disassembly and cleaning, with features like quick-release parts 또는 washable components to reduce downtime.

3. What are the potential consequences of cross-contamination, and how to avoid them?

Cross-contamination is a significant concern when using a capsule filler equipment for different products, especially in the case of potent APIs or allergens. Here’s how to mitigate the risks:

◼ Dedicated Equipment: Use separate machines for different products if cross-contamination is a major concern.

◼ Cleaning Protocols: Implement strict cleaning and validation procedures. This includes rinse swab testing and visual inspections to ensure all traces of previous products are removed.

◼ Containment Systems: Some capsule machines feature containment systems or isolators to prevent cross-contamination. These systems include glove boxes or sealed chambers that protect operators and prevent product mix-ups.

◼ Dust Extraction: Using dust collection systems 그리고 air purging systems can help minimize the chances of cross-contamination due to airborne particles.

By following cGMP guidelines and incorporating appropriate containment features, the risk of cross-contamination can be significantly reduced.