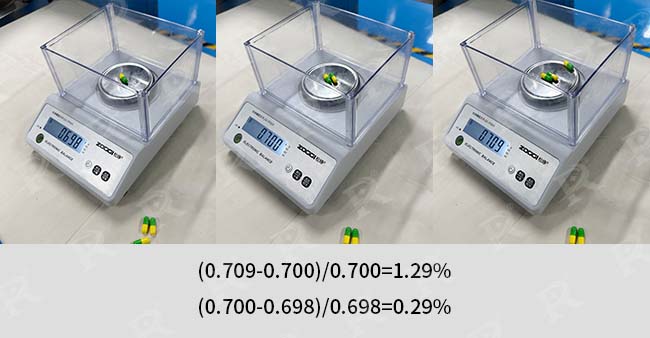

August 18, 2025, Malaysian client Luis visited Ruidapacking to test the NJP-1500D 캡슐 충전 기계. His goal was to ensure the capsule filler accuracy remained within ±2%, using a sampling method where 2 capsules were checked per 1,000, repeated 10 times. He told Emmy:

“Although the testing process had some challenges, the results were excellent. Your engineers and sales managers demonstrated strong professionalism. I hope we can establish a long-term partnership.”

Why Did Luis Visit the Factory for Testing?

Luis, a Production Director at a Malaysian pharmaceutical company, primarily manufactures capsules for international brands. His previous experience with a Chinese supplier was disappointing—despite online video demonstrations , the machine he received failed to meet the ±2% accuracy requirement, and after-sales support was lacking, rendering the equipment unusable.

This time, Luis wanted to see the machine in action and verify Ruidapacking’s production capabilities and after-sales service before committing.

Why Was the Filling Accuracy Unstable for Sticky Materials?

Luis brought two types of materials:

1.Free-flowing powder– Tested first, achieving ±2% accuracy consistently.

2.Sticky, viscous powder – Initially failed to meet accuracy standards.

Engineer Yang had pre-cleaned and maintained the machine to save time. However, when testing the sticky material:

- Initial samples exceeded ±2% variance.

- Adjusting to maximum fill volume (fully filling size 0 capsules) still didn’t resolve the issue.

After 30 minutes of troubleshooting, the engineering team suspected temperature and humidity effects. They moved the machine into a climate-controlled lab, letting it sit for 2 hours before retesting.

How Temperature & Humidity Affect Filling Accuracy

At 2:00 PM, the team resumed testing:

- The sticky material was loaded again.

- 10 samples (2 capsules each) were taken after 10 minutes of operation.

- High-precision scales confirmed all samples accuracy<±2% .

Both Luis and the engineers smiled in relief—the issue was resolved.

Key Takeaways

Free-flowing powders typically meet accuracy standards easily.

Sticky materials are sensitive to temperature & humidity—requiring controlled environments.

Luis concluded: “I’m very satisfied with this China visit. I’ll report back to management and highly recommend your company’s automatic capsule filling machine. You’ll also be our preferred supplier for blister packaging machine and cartoning machine—if needed, we’ll prioritize Ruidapacking at equal pricing.”

Emmy responded: “We don’t just sell machines—we ensure global clients receive high-quality pharmaceutical equipment.”