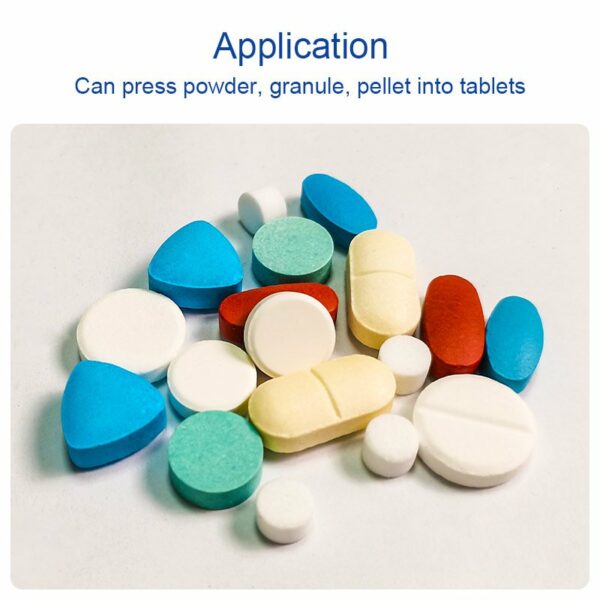

医療用錠剤製造機

医療用錠剤製造機は、一貫したサイズ、重量、硬度の錠剤を製造するために、体系的な圧縮メカニズムで動作します。以下は、その動作原理です:

供給とダイフィリング粉末や顆粒はホッパーに投入され、回転するダイシステムに導かれます。ダイは錠剤の形と大きさを決める空洞です。.

予備圧縮:初期圧力をかけてエアポケットを除去し、均一な密度を確保する。.

主圧縮:上パンチと下パンチが高い圧力(最大100kN)をかけ、粉末を固形の錠剤に圧縮する。.

排出:完成した錠剤はダイから押し出され、包装のために回収される。.

最新のロータリー式錠剤機はこの工程を自動化し、10,000~90万個/時の速度を達成します。高度なモデルでは、FDAやGMP基準に準拠した品質を維持するために、力制御システムとリアルタイム監視が統合されています。.

仕様:

最大110,000タブ/時

錠剤の最大直径24mm

15日間の迅速な配送