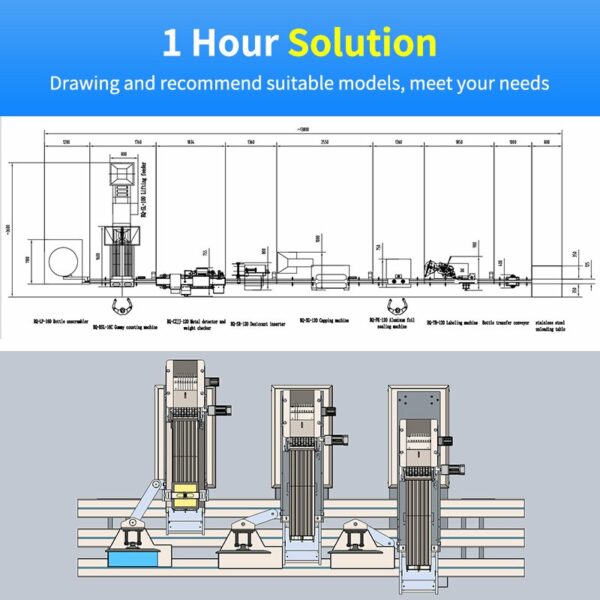

錠剤・カプセルの充填ライン

錠剤・カプセル製造用のカウントボトリングラインは、医薬品の効率的かつ正確なパッケージングを保証するために設計された一連の調整された手順を通じて稼働します。

計数機各ボトルが充填ステーションに到着すると、ノズルが計数された錠剤またはカプセルをボトルに注入します。

キャッパーマシン:キャッパーマシンは、各ボトルにキャップを装着し、締め付けます。この工程では、ねじ込み式、押し込み式、スナップオン式など、様々なタイプのキャッピング方法を使用できます。

シーラー: 不正開封防止包装の場合、誘導シーラーを使用して、ボトルの開口部に熱シールされたホイルを貼り付けることができます。

ラベリング マシン: 次に、ボトルはラベリング ステーションに運ばれ、そこで製品情報、バッチ番号、有効期限が記載されたラベルが貼られます。

仕様:

最大70本/分

15日で配達

3〜40mmの錠剤、カプセル、グミなどに適しています。