Gummy supplements have rapidly transformed from a niche format into one of the fastest-growing product categories in the global nutraceuticals market. Their pleasant taste, portability, and high consumer acceptance make them a preferred delivery system for vitamins, minerals, collagen, functional botanicals, and more. This surge in demand has also reshaped the manufacturing landscape. Producers are under pressure to deliver consistent quality at scale and to solve the unique challenges posed by sticky, pliable, irregularly shaped gummies.

From ingredient hydration and molding to counting, bottling, and pouch packaging, the journey of a gummy product is far more complex than it appears. This article unpacks the full production process and introduces equipment innovations that have proven critical in helping manufacturers overcome gummy-specific challenges while boosting throughput, accuracy, and reliability.

Gummy Manufacturing Process

Producing gummies is a hybrid discipline that intertwines food science, precision mechanics, and strict quality controls. A gummy making machine orchestrates a multi-stage process that ensures uniformity in texture, flavor, dosage, and appearance.

1. Hydration, Dissolution, and Homogeneous Mixing

The process begins in a heated mixing tank where gelatin, pectin or other gelling agents, glucose syrup, sweeteners, colorants, vitamins, and functional ingredients are carefully proportioned. Precise temperature control ensures the mixture dissolves evenly without overheating, which is critical for vitamin retention and final texture.

2. Flavoring and Coloring

Once the mixture reaches the desired viscosity, it is transferred to a secondary flavoring tank. Here, natural fruit flavors, plant extracts, or functional actives are added. This step allows fine-tuning and ensures each gummy delivers consistent taste and nutritional value.

3. Vacuum Deaeration and Molding

Air incorporated during mixing must be removed to avoid defects. Vacuum deaeration eliminates bubbles, resulting in smooth, uniform gummies. Precision pumps then transfer the mixture to the depositor system, which injects controlled quantities into each mold cavity as the molds move along the conveyor.

4. Cooling and Setting

The filled molds travel through a controlled-temperature cooling tunnel. Steady, low-temperature cooling ensures structural integrity, prevents stickiness, and locks in the intended shape.

5. Demolding, Polishing, and Final Conditioning

After setting, gummies are released from their molds. They then enter a polishing drum where a thin coating of food-grade oil or carnauba wax is applied for shine, texture enhancement, and initial anti-stick performance.

At this point, the gummies are ready for packaging. However, packaging presents an entirely new set of technical challenges.

Why Gummy Packaging Is Uniquely Difficult

Unlike tablets or capsules, gummies are soft, moist, and often sugar-coated. These characteristics make them susceptible to clumping, bridging, and adhesion during automatic counting or weighing.

Common issues include:

Gummies sticking to stainless steel surfaces

Multiple gummies dropping together, resulting in miscounts

Blockages at feeding channels

Slow flow rate when transitioning from bulk hopper to counting system

Inconsistent separation during high-speed vibratory conveyance

For manufacturers scaling production, these issues directly impact throughput, accuracy, downtime, and ultimately profitability. This is why gummy-specific packaging technologies have become essential.

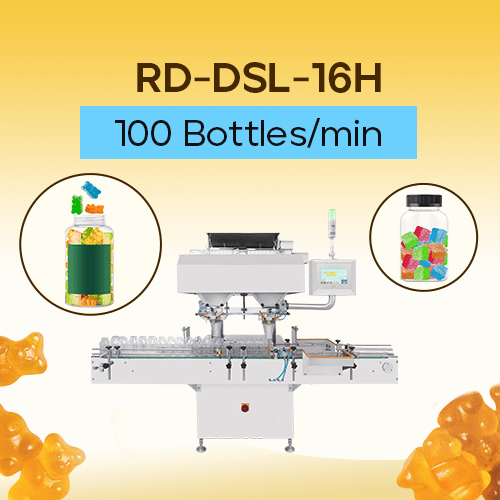

Gummy Counting Machine: Engineering Built for Sticky Challenges

To address the gummy industry’s biggest pain points, the RD-DSL-16H high-speed counting machine integrates a set of engineering innovations designed specifically for sticky, irregular, sugar-coated, or large-sized gummies. These features significantly reduce blockage, improve flow, and enhance counting accuracy.

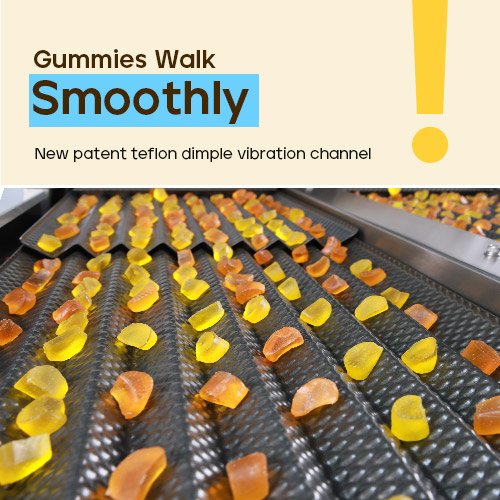

1. Teflon-Coated, Streamlined “Raindrop” Contact Surfaces

All surfaces in contact with gummies are coated in food-grade Teflon. Combined with a raindrop-shaped structural design, this dramatically lowers friction. Gummies glide smoothly over channels and vibration plates, separating naturally without sticking.

2. Pre-Separation Stainless-Steel Stirring Rod

A continuously rotating 316L stainless-steel stirring bar at the hopper entrance gently breaks apart clusters. This proactive dispersion prevents initial clumping before gummies even reach the counting channels.

3. PTFE Precision Flow Separator

A proprietary PTFE separator positioned at the transition point between hopper and vibrating chute ensures that only one gummy at a time can enter. If two gummies are stuck together, neither is allowed through until they separate. This guarantees complete single-piece flow into the counting track.

4. Enlarged PTFE Discharge Port for High-Volume Bottling

To accommodate larger gummies and avoid bottlenecking during high-speed bottle filling, the machine features an enlarged discharge port constructed from ultra-smooth PTFE. Even during rapid, continuous operations, gummies drop freely without compression or jamming.

5. Pneumatic Vibratory Bottle-Entry Nozzle

The discharge nozzle operates with soft pneumatic vibrations, preventing gummies from getting trapped at the edge of the bottle opening. This ensures stable, accurate filling and minimizes miscounts at the final moment.

Combined, these features deliver a production solution that is both high-speed and highly reliable, even for the most difficult gummy formulations.

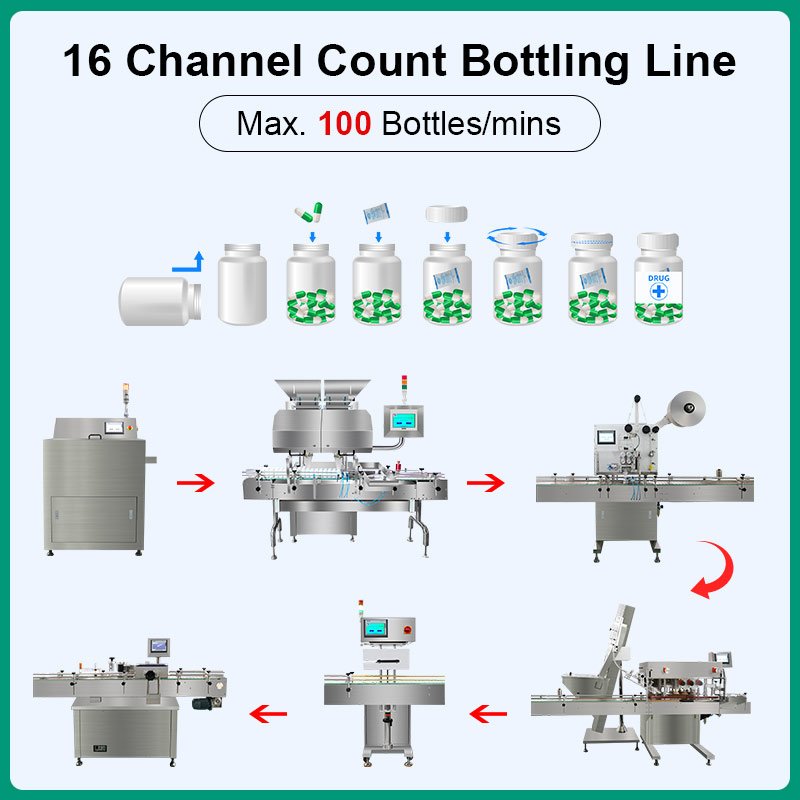

Complete Counting Bottling Line Solutions

A counting machine alone is only part of the full production workflow. For supplement brands and contract manufacturers targeting large-scale output, a automatic gummy bottling line offers productivity advantages, quality consistency, and labor savings.

A full-automation gummy bottling line includes:

Bottle Unscrambler: Automatically organizes empty bottles and places them in uniform orientation.

High-Speed Counting Machine: Counts and fills gummies with accuracy and repeatability.

Metal Detector: Ensures no metallic contaminants enter the final product.

Checkweigher: Verifies bottle weight to detect overfill or underfill conditions.

Capping Machine: Automatically applies and tightens screw caps at high throughput.

Induction Sealing Machine: Creates a hermetic seal under the cap to maintain freshness and prevent tampering.

Labeling or Sleeve-Label Application: Applies branding, nutrition information, and regulatory labels with precision.

Coding and Marking System: Prints batch numbers, expiry dates, and traceability codes.

Together, these elements streamline operations from end to end, creating a cohesive, cGMP-compliant production environment that is ready for global distribution.

Flexible Packaging Options: When Gummies Go into Pouches

While bottles remain the mainstream format for nutraceutical gummies, flexible packaging is growing rapidly. Pre-made pouch packing machine are increasingly adopted for single-serve and family-size gummy packs.

These systems follow a structured workflow:

1. Pick-up of pre-made pouch

2. Automatic opening and inflation of the pouch

3. Filling via multihead weigher or counting system

4. Optional nitrogen flushing

5. Sealing through controlled heat pressure

6. Output of the finished package ready for boxing

Advantages include:

Enhanced cost-efficiency for larger volume

Lightweight, eco-friendly packaging options

High retail appeal with flexible printing styles

Fast changeover for different pouch sizes and designs

This format is especially attractive for gummies sold in mass retail, club stores, or e-commerce bundles.

The explosive growth of the global gummy supplement market has raised the bar for production capabilities. Manufacturers today need not only excellent formulation and processing control, but also highly specialized packaging solutions capable of handling the inherently sticky nature of gummies with precision and efficiency.

From the intricate science of gummy formation to the engineering breakthroughs in anti-stick counting, filling, and sealing technologies, the entire workflow must operate as a cohesive, highly tuned system. Equipment such as the high-speed gummy counting machine demonstrates how design innovations directly solve production pain points, reduce downtime, and support consistent output at scale.

Whether your operation focuses on bottles, pouches, or both, a complete, integrated solution ensures product quality, regulatory compliance, and market competitiveness. As demand continues to rise, investing in the right manufacturing and packaging technology becomes not just a productivity gain, but a strategic advantage for any nutraceutical brand aiming to lead in the global gummy market.