- Casa

- Macchina di conteggio automatica

Macchina di conteggio automatica

Può confezionare tutti i tipi di capsule, compresse e caramelle gommose in un unico flacone, il che lo rende adatto a istituti di ricerca scientifica, ospedali, fabbriche farmaceutiche, prodotti per la salute e imballaggi per la produzione industriale. Può anche essere integrato con astucciatrice, etichettatrice, ecc.

Applicazione:

La macchina contatrice automatica è adatta a diverse applicazioni, tra cui capsule, compresse e caramelle gommose.

Capsula (000~5#)

Tavoletta (3-40 mm)

Gommosa (3-40 mm)

Come funziona

Oltre al semplice conteggio e al riempimento di compresse e capsule nei flaconi, la macchina contatrice automatica Rich Packing è dotata di sezioni di lavoro e tecnologie per garantire un processo di produzione fluido ed efficiente.

Ordinamento delle bottiglie

Organizzazione di tutte le bottiglie per la preparazione del riempimento.

Ingredienti per il ripieno

Inserimento di tutti i materiali nella macchina contatrice.

Conteggio

Allineamento in canali. Capsule, compresse o caramelle gommose possono essere contate e riempite fino a 9000 bottiglie/ora.

Iniettare pillole

Iniettare pillole in flaconi con tecnologia brevettata non è una carenza.

Smaltimento dei rifiuti

Smaltimento delle bottiglie difettose.

La gamma completa di macchine contatrici automatiche

Un'ampia varietà di modelli di macchine con capacità e budget diversi tra cui scegliere.

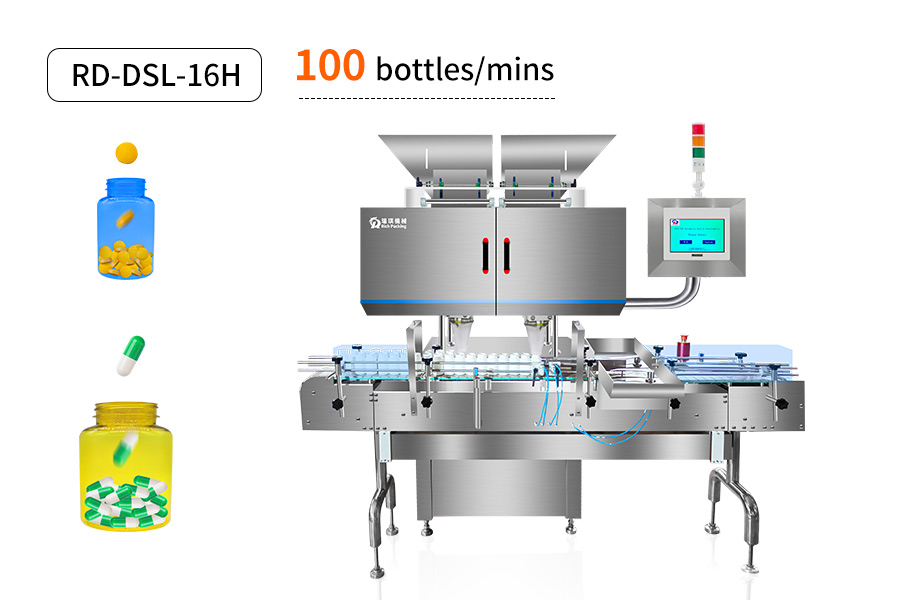

| Modello | 8B | 12B | 16B | 16R | 16 ore | |

| Capacità | 10-35 bottiglie/minuto | 15-45 bottiglie/minuto | 20-85 bottiglie/minuto | 100 bottiglie/minuto | 127 bottiglie/minuto | |

| Materiale capace | Capsule/compresse/gommose da 2-40 mm... | |||||

| Tasso di precisione | >99,8% | >99.97% | >99.98% | |||

Macchina riempitrice per il conteggio di compresse e capsule

Tablet and capsule counting filling machine involves several precise steps designed to ensure accurate counting and efficient filling into ...

Hai bisogno di un altro modello di macchina?

Applicazione più ampia:

Conteggio

Caramelle gommose, caramelle…

Oltre a essere disponibile solo per compresse o capsule, la nostra macchina contatrice, dotata di tecnologie speciali, è in grado di contare e riempire anche integratori alimentari, come vitamine e persino caramelle gommose. Questo può ampliare le possibilità della tua attività.

- Il design della leva separata consente uno scorrimento continuo che impedisce il bloccaggio.

- Il rivestimento in teflon sul canale consente un'erogazione fluida

- Ampia tramoggia in PTFE senza intasamento gommoso

Linea di conteggio completamente automatica

Progettata per funzionare completamente, dalla disordinazione del flacone all'applicazione dell'adesivo, la linea di conteggio automatica è progettata per aiutarti a disporre le tue capsule o compresse in un flacone che include tutto il necessario senza problemi. È conveniente e adatta a un'ampia gamma di formati di compresse.

Riordinatore di bottiglie

Macchina contatrice

Inseritore di essiccante

Macchina sigillatrice per fogli di alluminio

Macchina tappatrice

Etichettatrice

Un aiuto per imballare i tuoi prodotti

Ci impegniamo a realizzare macchine di qualità superiore che soddisfino gli standard GMP, dotate al contempo di funzionalità ed efficienza.

Efficiente senza pillola bloccata

50% più veloce rispetto a modelli simili di altri produttori e la pillola non si incastra grazie al design a riempimento pneumatico.

Protezione dalle pillole

La macchina contatrice non danneggia le pillole durante il processo, riducendo così lo spreco di materiale e i costi di manodopera per l'ispezione.

Stabile attorno alla polvere

Le nostre macchine contatrici resistenti alla polvere possono continuare a funzionare normalmente e mantenere prestazioni efficienti anche in condizioni di polvere.

Sistema di rifiuto automatico

In caso di capsule o compresse non conformi, l'intera confezione verrà automaticamente spostata lateralmente.

Ti copriamo le spalle con un servizio completo

Ti supportiamo durante tutto il processo, dalla scelta della macchina adatta alla cura che ne durerà per tutta la vita.

Garanzia a vita

Per garantire prestazioni eccellenti a lungo termine, offriamo riparazioni gratuite entro 3 anni e ricambi gratuiti entro 1 anno. Successivamente, garantiamo una consulenza tecnica gratuita a vita.

Consegna rapida in 7 giorni

95% delle nostre macchine standard sono disponibili a magazzino. In tal caso, la spedizione può avvenire entro 7 giorni. Per i prodotti personalizzati, la consegna richiede solo 20 giorni.

Servizio online 24 ore su 24, 7 giorni su 7

I nostri esperti clienti e i nostri ingegneri competenti risponderanno alle tue esigenze e risolveranno tutti i tuoi problemi entro 24 ore.

Domande frequenti

Sì, la nostra macchina contacapsule può contare le compresse senza apportare alcuna modifica.

Sì, possiamo integrare la macchina contacapsule con la macchina riempitrice per te. E se hai bisogno anche di una macchina astucciatrice integrata, possiamo fornirti una soluzione. Contattaci con i tuoi dati specifici.

CE: Conforme Europeo GMP: Buone Pratiche di Fabbricazione ISO: Organizzazione Internazionale per la Normazione FDA: Food and Drug Administration

Ecco alcuni aspetti specifici da considerare, come le dimensioni del prodotto, la capacità produttiva, le dimensioni della macchina e la garanzia. Dato che il costo della macchina rappresenta un budget elevato, un servizio post-vendita completo e duraturo può essere di grande aiuto per un'attività a lungo termine.

Sì, non esitate a inviarci le specifiche e vi forniremo una soluzione adatta alle vostre esigenze. Le nostre macchine possono coprire la maggior parte delle dimensioni e possiamo anche fornire servizi di personalizzazione.

- Controllare e pulire la parte elettrica per accertarsi che sia in ordine e priva di polvere, per evitare guasti alla linea.

- Pulire la piastra antiurto per evitare la corrosione una volta completata la produzione.