Walk down any pharmacy, supermarket, or consumer goods aisle. The neatly arranged boxes you see—holding your over-the-counter medication, your new skincare product, or even a small electronic gadget—share a common origin. They were most likely assembled, filled, and closed not by human hands, but by the precise, relentless work of a cartoning machine. Often the unsung hero of modern packaging lines, this equipment is fundamental to efficiency, hygiene, and speed in countless industries.

For those involved in manufacturing and packaging, understanding the capabilities of cartoning machines is not just technical knowledge—it’s a key to optimizing production flow and staying competitive.

How Does a Cartoning Machine Work?

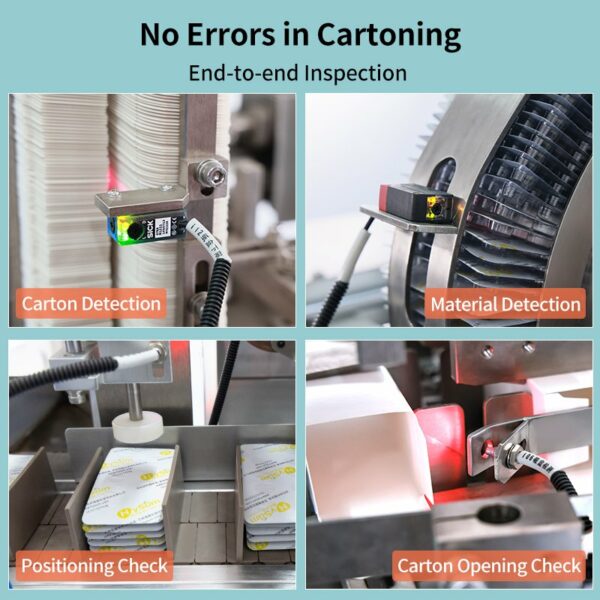

At the heart of a cartoning machine is the process of automatically placing products into folded cartons and sealing them. While configurations vary, the fundamental operation follows a clean, logical sequence that ensures remarkable reliability. The process can be broken down into four key stages:

Box Erection: The machine takes folded cartons from a cartons feeder device. A suction cup or mechanical arm picks up a single blank, opens it, and forms it into a rectangular box shape. At this stage, the box is open at both ends, ready to receive its contents.

Product Loading: This is the heart of the operation. The formed box is transported through the machine via a conveyor chain. As it moves, the product is inserted. Mainly, blister sheets, bottles, small bags and other products are transported by conveyor belts. The folding machine automatically folds the prepared instructions and moves with the product. When the box, product and instructions are in the same position, the push rod pushes the product and instructions into the box, and the pushing is completed.

Folding and Sealing: After the product and instructions are placed in the box, the two small ears at the box opening are folded by a mechanical device, the box tongue passes through the batch number printing device, and then passes through the mechanical tongue insertion device. If necessary, a hot melt glue machine can be configured at the tongue insertion station for sealing.

Discharge: The securely sealed and now fully packaged box is discharged onto a takeaway conveyor. It is now ready for the next step in the process, which could be bundling, case packing, or labeling.

This seamless, continuous cycle demonstrates a perfect marriage of mechanical engineering and practical application.

Versatility in Action

The true strength of a cartoning machine lies in its adaptability. It is not confined to a single industry or product type. Its ability to handle a diverse range of items makes it an indispensable asset.

Pharmaceuticals: This is a primary application. Cartoners are used to package blisters (medicine packs), providing essential patient information and tamper evidence. They also efficiently handle bottles of cough syrup or supplements, and small tubes of ointments or creams.

Food & Beverage: From tea bags and soup sachets to individually boxed bakery items or specialty coffee pods, cartoners add a layer of protection and brand presentation.

Cosmetics & Personal Care: Luxury soaps, bottles of lotion, and skincare tubes are often presented in elegant boxes, a task perfectly suited for high-speed, gentle-action cartoners.

Consumer Goods: Small electronics, hardware items (like lightbulbs), and stationery products all benefit from the structured protection and professional presentation a carton provides.

Creating a Seamless Packaging Line

While a standalone cartoning machine boosts productivity, its real potential is unlocked when integrated with other packaging equipment. This creates a synchronized, end-to-end packaging line that minimizes manual handling, reduces labor costs, and maximizes throughput.

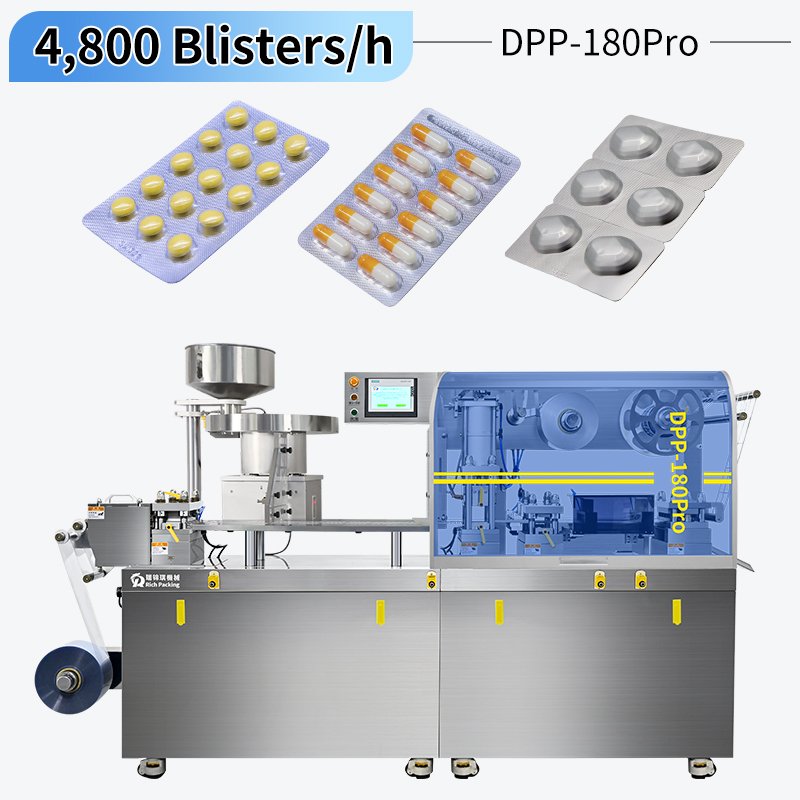

Integration with a Blister Packaging Machine

In pharmaceutical packaging, this is a classic and highly efficient combination. A blister machine forms the plastic cavities, fills them with tablets or capsules, and seals them with a foil lid. The completed blister pack is then conveyed directly into the waiting carton of the cartoning machine. An automatic leaflet feeder is often integrated at this point, placing the information leaflet into the box alongside the blister pack. This creates a continuous, high-speed line from loose pills to a fully packaged, compliant, and consumer-ready product.

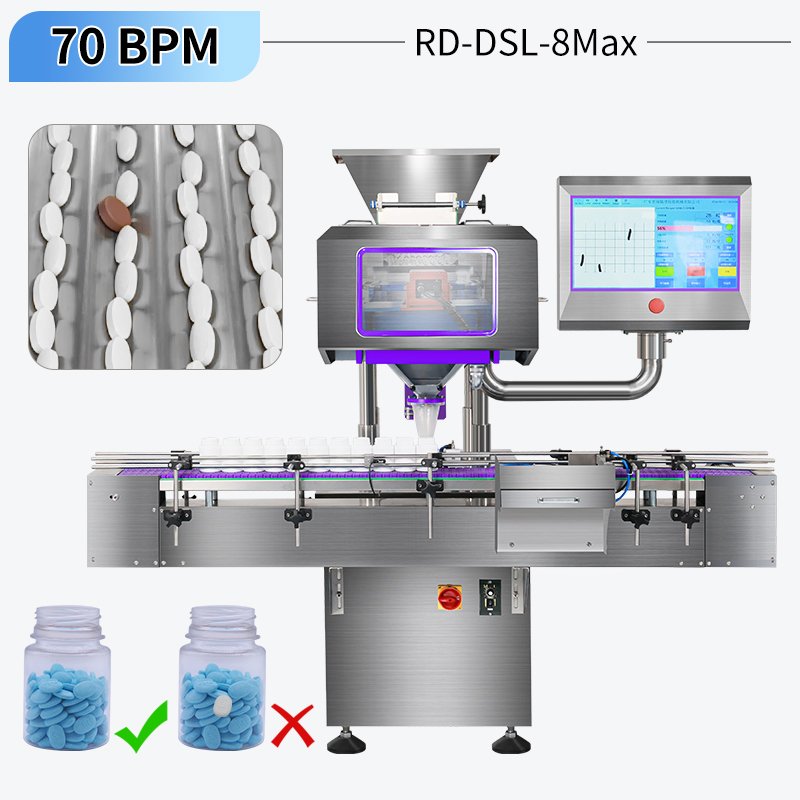

Integration with a Bottle Counting and Filling Line

For products like vitamins, supplements, or items sold by count (tablets or capsules), integration with a tablet capsule counting bottling line is essential. The counting line fills plastic bottles with a precise number of items and applies a cap. These filled bottles are then transported directly to the cartoning machine, which erects a box, inserts the bottle, and often adds a leaflet before sealing. This integration ensures count accuracy and creates a smooth, uninterrupted flow from bulk components to finished, boxed goods.

Kesimpulan

A cartoning machine is far more than a simple box-closer. It is a versatile, precise, and intelligent system that forms the crucial bridge between primary packaging (blisters, bottles, sachets, tubes) and the final product that reaches the consumer. Its ability to handle a wide array of products and, most importantly, to integrate seamlessly into automated packaging lines, makes it a cornerstone of modern manufacturing. By ensuring speed, consistency, and hygiene, it not only protects products but also powerfully communicates brand quality and value on shelves around the world. Investing in the right cartoning solution is a strategic decision for any business looking to streamline operations and enhance its market presence.