1. What Is Capsule Filling Machine

Le machine de remplissage de capsules is the preferred equipment in the pharmaceutical industry. It can fill powders, granules, and pellets into empty capsules, suitable for capsule sizes #000 to #5, meeting your needs.

2. Different Types of Capsule Filling Machines

Based on the level of automation, the industry classifies capsule filling machines into three categories: manual capsule filling machines, semi-automatic capsule filling machines, and fully automatic capsule filling machines. All of them function to fill empty capsules with medication powder, with the main difference being the degree of your involvement. Here is a brief introduction to these three types of capsule filling machines.

(1) Manual Capsule Filling Machine

Manual capsule filling machine, as the name suggests, requires the operator to perform all tasks, including capsule separation, filling, and locking.

(2) Semi Automatic Capsule Fillier

Semi-automatic capsule filler handles most of the work automatically. You only need to issue commands on the touchscreen at different time points. The output is approximately 15,000 to 40,000 capsules per hour, depending primarily on the operator’s proficiency with the machine.

(3) Full Automatic Capsule Filling Machine

Fully automatic capsule filling machine is equipped with a vacuum capsule loading unit and a vacuum powder loading unit. Once the materials are prepared, you simply start and stop the process on the PLC (Programmable Logic Controller), and everything else is done automatically.

3. Capsule Filling Machine Working Principle

Do you know how it works? Let’s take a look at how capsule filling machines operate.

(1) Manual Capsule Filling Machine

The manual capsule filling machine consists of a body plate, cap plate, middle plate, alignment plate, tamping plate, and powder scraping plate. Operators first separate purchased empty capsules into caps and bodies. The body plate and alignment plate are aligned, and the capsule bodies are placed on the alignment plate. After a rotation, the capsule bodies on the body plate are filled. The process for the cap plate and body plate is similar; once filled, they are set aside. Powder is added onto the body plate and leveled with the scraping plate. The middle plate covers the cap plate to prevent caps from falling off. The cap plate is pressed down onto the body plate with force, locking the capsules into place, thus forming complete capsules.

(2) Semi Automatic Capsule Filling Machine

Le semi-automatic capsule filling machine operates in three main steps: capsule sorting, filling, and locking, all controlled via a touchscreen interface. Here’s a breakdown of its operation:

① Preparation:

Power and air supply are turned on. A suitable number of empty capsules are placed in the hopper.

The filling material is loaded into the filling cylinder.

The capsule tray is positioned at the sorting station, and initial setup is completed.

② Capsule Sorting:

The vacuum pump is activated. By selecting “Capsule Sowing” on the touchscreen, the machine begins operation.

Empty capsules are automatically placed into the capsule tray. Caps are oriented with caps facing upward and bodies downward. Once sorting is done, the tray rotates automatically. Due to suction underneath the tray, capsule bodies are drawn downward, separating them from the caps.

③ Powder Filling:

The operator moves the capsule tray from the sorting station to the filling station.

The upper half of the capsule tray is positioned aside. “Filling” is selected on the touchscreen to activate the filling station.

Powder is filled into the capsule caps. If necessary, secondary filling can be performed. After the first filling, the tamping plate is used to compact the powder on the tray. Another filling round can achieve multiple fills if needed.

④ Capsule Locking:

Once filling is completed, the upper and lower parts of the capsule tray are closed together.

The tray is then placed at the locking station. Press the locking button, the machine automatically locks the capsules.

Complete capsules are discharged from the outlet, completing the entire process.

This semi-automatic machine streamlines capsule filling operations while allowing operators to monitor and control the process through a user-friendly touchscreen interface.

(3) Full automatic capsule filling machine

The fully automatic capsule filling machine completes all operations including sorting, capsule separation, filling, rejection, locking, ejection, and cleaning automatically. You only need to press “Run” on the touchscreen to initiate the process. To achieve full automation, it is equipped with a vacuum powder loading unit and an empty capsule loading unit.

Preparation:

Power and air supply are turned on. The vacuum powder loading unit is connected with a powder-filled hopper.

The empty capsule loading unit is loaded with sufficient empty capsules from a material bin.

Operation:

The empty capsules are automatically fed into the machine. When the capsules reach two-thirds capacity at the discharge port, the loading unit stops automatically. It resumes when capsules drop below one-third capacity.

Similar to the empty capsule loading unit, the vacuum powder loading unit operates automatically and is not detailed further.

Start the vacuum pump to begin automatic operation.

Capsule Sorting: The machine automatically sorts capsules with bodies below and caps above. An air hose connects to the power part of the sorting station, synchronizing with the capsule separation step.

Filling: Powder is compacted five times in the metering disc before filling into capsule bodies.

Rejection: Faulty or already locked capsules that cannot separate at the sorting station are rejected. A stainless steel needle at the rejection station ensures proper rejection: the needle normally rests against the capsule cap, and if the cap and body are not separated, the needle pushes the capsule body, which is instantly removed by suction.

Locking: The steel needle ensures proper capsule locking without piercing. Its curved shape protects capsules from damage.

Ejection: Finished capsules pass through a polishing machine at the ejection port, ensuring smooth edges and no residual powder.

Cleaning Station: Since powder residue can accumulate at various stages, the cleaning station uses suction to remove any leftover powder and dust.

4. Capsule Filling Machine Advantages

High filling accuracy: If precision in filling is a requirement, the fully automatic capsule filling machine can achieve ≤3% accuracy.

High production capacity: The fully automatic capsule filling machine from Guangdong Ruiqi can reach a maximum output of 468,000 capsules per hour. This enhances productivity and reduces labor costs, making it an ideal choice.

Ease of operation: Simply ensure an adequate supply of materials; the machine handles everything else automatically.

Safety: With no need for manual operation, safety is significantly improved.

Versatility: Suitable for capsule sizes #000 to #5, it can fill powders, granules, pellets, or liquids into empty capsules.

5. Application of Capsule Filling Machine

Capsule filling machines are widely used across various industries including pharmaceuticals, dietary supplements, and food.

6. How to Maintenance Capsule Filling Machine

Maintenance and upkeep of capsule filling machines are crucial for ensuring high efficiency and extending their operational lifespan.

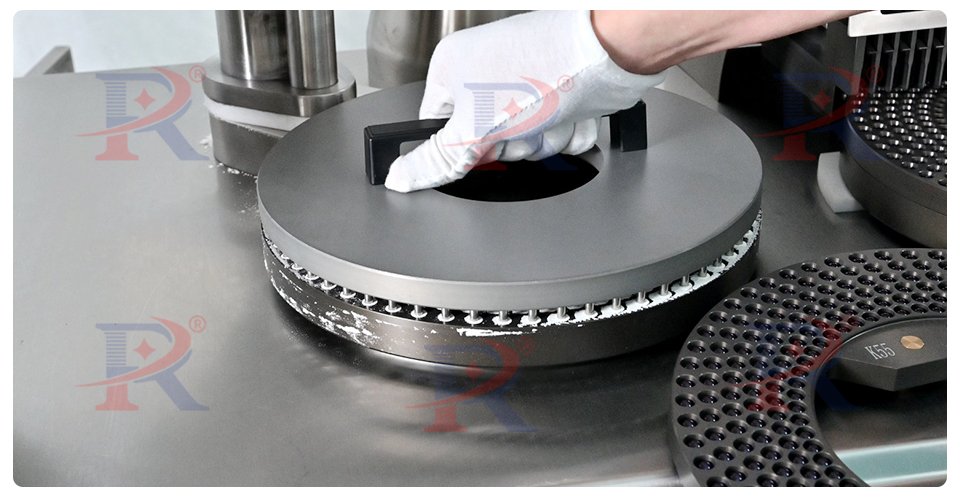

Daily Cleaning: After each operation, wipe down the turntable and all stations with a clean, dry cloth to prevent residual powder and dust, avoiding potential contamination during the next use.

Lubrication: Regularly lubricate bearings, gears, cams, and other components as per the manufacturer’s recommendations. Use lubricants specified by the manufacturer.

Inspection: Every two weeks, inspect oil and dust seals, gaskets, and springs for signs of wear and promptly replace them as needed.

Note: Machine maintenance should be conducted in accordance with the user manual or manufacturer’s guidelines to ensure optimal performance and longevity.

7. Development Trend of Capsule Filling Machines

With the development of the pharmaceutical and dietary supplement industries, there is a growing demand for capsules, driving the advancement of capsule filling machines towards automation and intelligence.

In the early 20th century, the first mechanical capsule machines were introduced, followed by semi-automatic and fully automatic capsule filling machines. Currently, the flagship technology in this field is the fully automatic capsule filling machine. However, some economically less developed countries or regions still use semi-automatic machines. As economies progress, technological advancements continue, and pharmaceutical standards become more stringent, the shift from semi-automatic to fully automatic machines is inevitable.

Looking ahead, the future of capsule filling machines will focus on automation and robotics, aiming for higher efficiency, advanced filling techniques, customization capabilities, and quicker changeovers between different product types and capsule sizes. Machines will also increasingly adhere to strict regulatory requirements, aligning with cGMP standards and enhancing traceability.

8. How to Choose Capsule Filling Machine

The choice of automatic encapsulation machine primarily depends on your production volume.

If your studio is newly established with limited budget and produces hundreds to thousands of capsules per day, a manual capsule filling machine is recommended.

For production volumes ranging from 100,000 to 150,000 capsules per hour, with moderate local labor costs, a semi-automatic capsule filling machine would be suitable. Additionally, if you need to perform secondary filling of powder, a semi-automatic machine is preferable as fully automatic machines cannot accommodate secondary filling.

If your production volume is high, manufacturing hundreds of thousands to millions of capsules per day, then a fully automatic capsule filling machine is the optimal choice.

9. FAQ on Capsule Filling Machine

Q: What is a capsule filling machine?

A: Capsule filling machine is a device used to fill various substances (such as powders, granules, pellets, or liquids) into empty hard capsules.

Q: What types of capsules can it fill?

A: Hard capsules.

Q: What materials can it fill?

A: Powders, granules, pellets, liquids, and mixtures.

Q: Does the capsule filling machine accommodate different capsule sizes?

A: Yes, it accommodates sizes #000 to #5.

The statements above reflect my limited understanding of capsule filling machines. If you have different perspectives or insights, I welcome your consultation and discussion.