Machine d'emballage de bandes pour comprimés

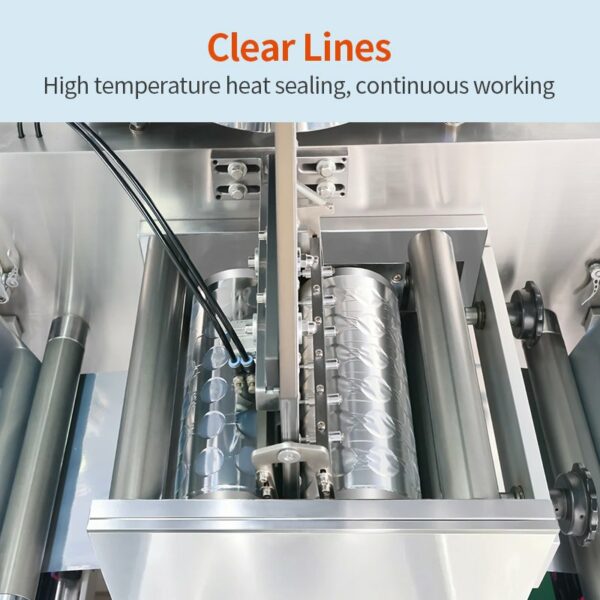

La machine d'emballage en bande est un modèle à cadence moyenne à élevée, spécialement développé par notre entreprise pour répondre aux principales préoccupations de nos clients en matière de protection contre la lumière, la résistance à l'humidité, la portabilité et la maîtrise des coûts des produits pharmaceutiques. Nous avons pris les devants pour résoudre des problèmes tels que les réglages complexes, la rupture et le désalignement des médicaments, la faiblesse de l'étanchéité, la facilité de déchirure et la découpe asynchrone.

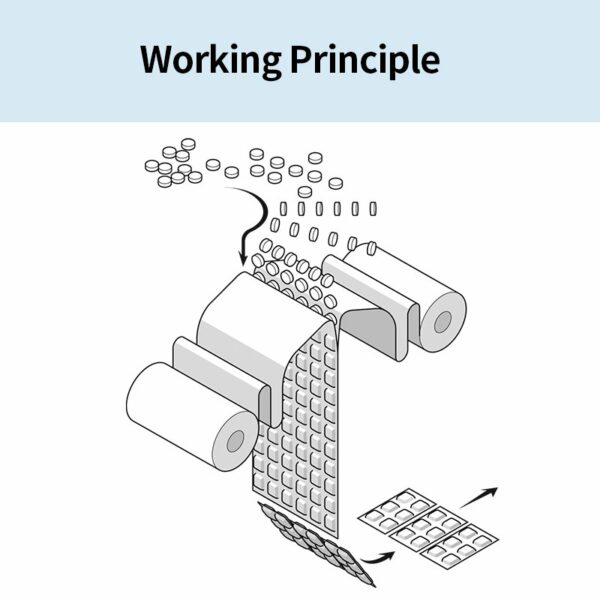

Cette machine réalise des processus entièrement automatisés, notamment l'alimentation des produits, le criblage des poudres, le tirage des films, l'emballage des produits, l'alignement du curseur, l'impression des numéros de lot, le gaufrage bidirectionnel, la découpe et le recyclage des bords des déchets, atteignant un niveau international avancé.

Les machines d'emballage à double feuille d'aluminium sont appréciées pour leur taille compacte et leur efficacité dans la protection des produits pharmaceutiques, leur coût inférieur par rapport à machines d'emballage sous blister.

Spécification:

Jusqu'à 4 800 pièces/h

Peut emballer des comprimés, des capsules, des pilules.

Livraison sous 7 jours