Étiqueteuse de bouteilles rondes

L'étiqueteuse de bouteilles rondes est conçue pour appliquer des étiquettes avec précision et efficacité sur des récipients cylindriques tels que des bouteilles, des pots ou des canettes.

Alimentation des conteneurs : les conteneurs sont placés sur le système de convoyeur.

Convoyeur à bande : Le convoyeur à bande transporte les contenants tout au long du processus d'étiquetage. La vitesse du convoyeur est synchronisée avec celle de l'étiqueteuse pour garantir une application précise des étiquettes.

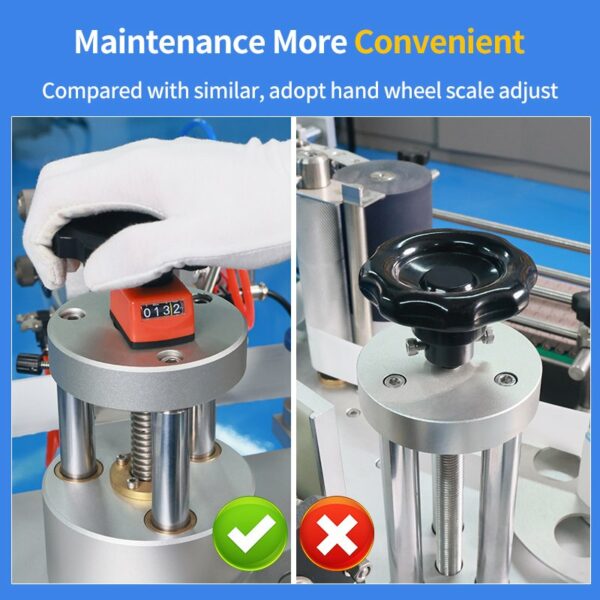

Roue ou vis d'espacement : Ce dispositif ajuste la distance entre les conteneurs pour garantir qu'ils entrent dans la station d'étiquetage aux intervalles corrects.

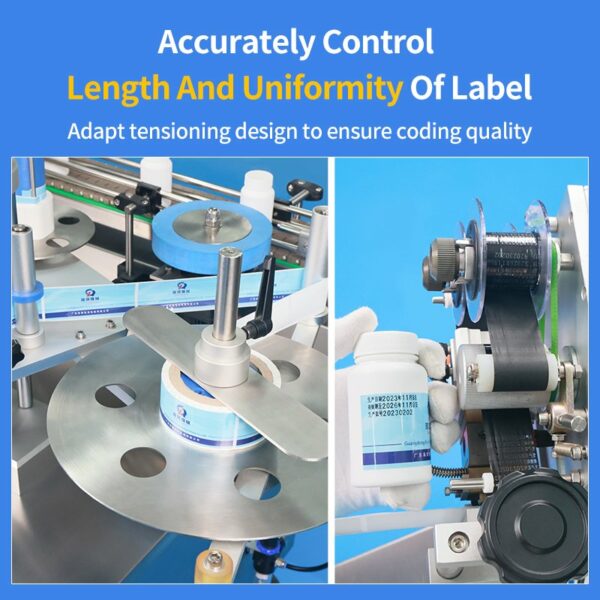

Capteur d'étiquettes : Un capteur détecte le bord avant de chaque étiquette pour garantir un positionnement précis. Ce capteur déclenche la distribution de l'étiquette au moment précis où le contenant passe devant le poste d'étiquetage.

Pinceau/rouleau applicateur : Lorsqu'un contenant passe devant le poste d'étiquetage, une étiquette est appliquée dessus. Possibilité de connexion au redresseur de bouteilles. machine de comptage automatique, machine à dessiccateur, machine à capsuler, machine à sceller dans la ligne d'embouteillage

Spécification:

Jusqu'à 120 bouteilles/min

Livraison en 7 jours

Convient à diverses bouteilles rondes