Enveloppeuse à flux à grande vitesse

L'emballeuse à flux à grande vitesse est basée sur le mouvement continu du matériau d'emballage, qui est utilisé pour emballer les produits de manière efficace et à grande vitesse.

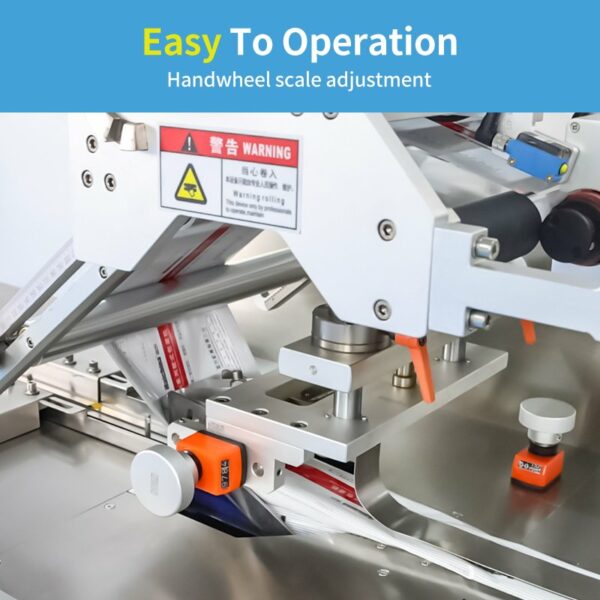

Un rouleau de film d'emballage souple (généralement en plastique) est monté sur la machine. Le film est ensuite retiré du rouleau et déplacé dans la machine.

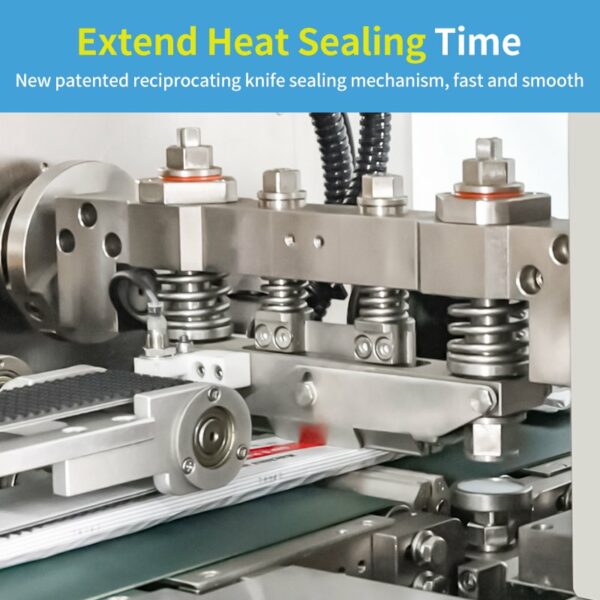

Le produit est introduit dans le tube de film formé. La machine le déplace en continu à travers le sachet. Le film est ensuite enroulé autour du produit, puis les bords sont scellés par des mécanismes de thermoscellage, formant ainsi l'emballage.

Aux deux extrémités du produit emballé, un ensemble de mâchoires de scellage se ferme, créant ainsi des soudures hermétiques au début et à la fin de l'emballage. Ces soudures sont généralement réalisées par thermoscellage ou par ultrasons, selon le matériau.

Après la découpe, le produit emballé sort de la machine, prêt pour un traitement ultérieur ou mise en carton.

Spécification:

Jusqu'à 180 sacs/min

Largeur maximale du film 350 mm

Convient aux industries pharmaceutiques, alimentaires, chimiques, des biens de consommation, etc.