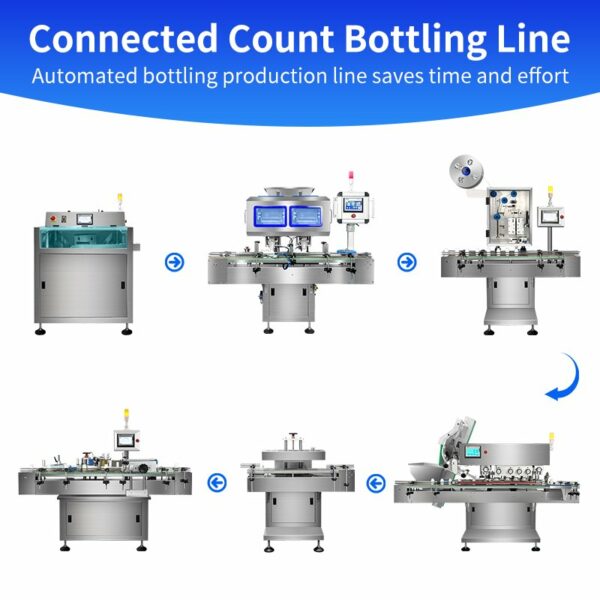

Machine de capsulage à grande vitesse

La machine de bouchage à grande vitesse est utilisée dans diverses industries pour placer et fixer les bouchons sur les conteneurs rapidement et efficacement.

Goulotte à bouchons : Les bouchons triés sont transférés vers une goulotte qui les guide vers la tête de capsulage. Cette goulotte assure un approvisionnement continu et régulier en bouchons vers le mécanisme de capsulage. Les contenants sont positionnés avec précision sous la tête de capsulage grâce à une roue crantée ou une vis de réglage.

Réglage du couple : La capsuleuse est équipée d'un système de contrôle du couple pour garantir une application correcte des bouchons. Cela évite tout serrage excessif ou insuffisant, garantissant ainsi une fermeture parfaite sans endommager le récipient ni le bouchon.

Contrôle qualité : Après le bouchage, les contenants passent par un poste d'inspection. Des capteurs ou des caméras vérifient le bon positionnement et l'étanchéité du bouchon. Les contenants défectueux sont automatiquement rejetés de la ligne.

Convoyeur de sortie : les conteneurs correctement fermés sont transportés vers le convoyeur de sortie, où ils sont collectés pour un traitement ultérieur, tel que étiquetage ou emballage.

Spécification:

Jusqu'à 120 bouteilles/min

Livraison en 7 jours

Convient à une large gamme de formes de bouteilles et de bouchons